The Employee-Owned Advantage

This Ohio shop is 100-percent employee-owned. Thus, both management and shopfloor employees recognize the importance of optimizing efficiency wherever possible. Thanks to a strong willingness to invest in and embrace new technologies, sales-per-employee has increased by more than 50 percent in the last five years.

Share

It takes more for a shop to prosper than simply purchasing advanced machining equipment. Shopfloor employees must be willing to welcome new technologies and techniques for a shop to succeed. Scott Carter says the personnel at Mansfield, Ohio’s Rable Machine hold that belief.

Mr. Carter, the shop’s president and CEO, points out that the company has invested $5 million in new manufacturing equipment during the last five years. As a result, the average sales per employee has increased by 53 percent in that time span. Mr. Carter notes that while it was important to integrate advanced Swiss-type lathes, dual-turret and dual-spindle turning centers as well as various elements of automation, it was the shopfloor employees’ willingness to embrace change that ultimately led to improved sales.

What bolsters this culture of continuous improvement is the fact that Rable Machine exists as an ESOP—an Employee Stock Ownership Plan. All 72 employee-owners are stock shareholders in the company with a direct financial stake in its performance. That means management is willing to invest in equipment that will lead to greater efficiency on the shop floor. Just as importantly, those on the shop floor fully support the addition of multifunction machines and automation, for example, rather than fearing it.

“Because of our ownership culture and widespread business knowledge, our people are more open to change,” Mr. Carter explains. “Everyone understands that we have to keep moving forward to be competitive, so they embrace the influx of advanced processes, including automation.”

This mindset was clearly evident during a recent visit to Rable Machine’s clean new facility.

Employee-Owned Advantages

Frank Rebel (pronounced ´ra-bəl) began his business in 1946 to provide machined components to the growing number of appliance manufacturers in the area. In 2010, the company moved from what had become a cramped 29,000-square-foot building to a 53,000-square-foot former bottling plant. The larger facility enabled Rable Machine to more readily implement lean manufacturing and cellular machining strategies while greatly improving work flow through the shop. Today, Rable Machine provides parts and assemblies made from a variety of materials to customers in the medical; aerospace; automotive; HVAC; oil and gas; and pump and valve industries.

The company became 100-percent employee-owned in 1998. Rick Rupp, who had purchased the company from Mr. Rebel, was looking to exit the business around that time. Unfortunately, he had no family members to whom he might turn over the keys and no specific buyer for the healthy company. By choosing an ESOP as his succession plan, Mr. Rupp was able to realize tax advantages while putting shop ownership into the hands of all those who worked there.

In general terms, an ESOP is a trust, and the employee-owners are participants in that trust. Mr. Carter says that in the case of Rable Machine, the ESOP offers a number of attractive advantages for employees, such as annual stock distributions with the opportunity to grow value of existing and future shares as well as the ability to diversify employee portfolios to reduce risk and promote a stable return. The company also offers a quarterly gain sharing program based on manufacturing budget objectives, an annual profit sharing program, stock distributions as the value of company rises, and even a reduction reward program in which payouts are given to employees who identify ways processes can be improved.

Although the company is an ESOP, Rable Machine’s management still makes all major business decisions. That said, the shop has established an Employee Participation Group (EPG) made up of representatives from across a variety of departments and shifts to provide recommendations to top management related to specific projects and procedures. For instance, the EPG helped create the company’s attendance and hearing protection policies. In addition, the EPG is involved with shaping the shop’s wellness program. (The company set aside a portion of the new, larger facility to be used as an exercise room filled with equipment that employees are donating for use there. There are also plans to develop a walking trail on the company’s 13-acre lot.)

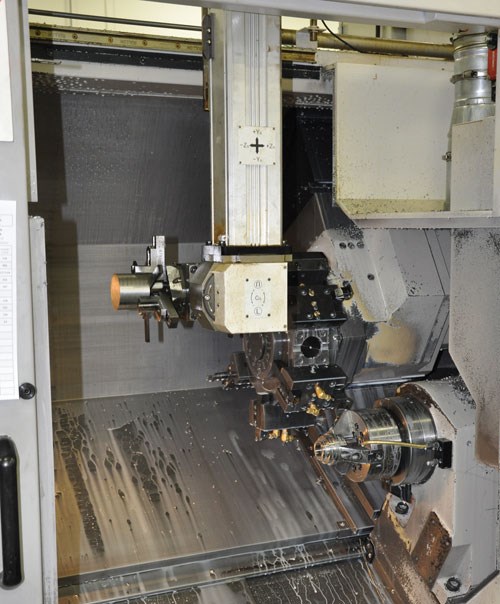

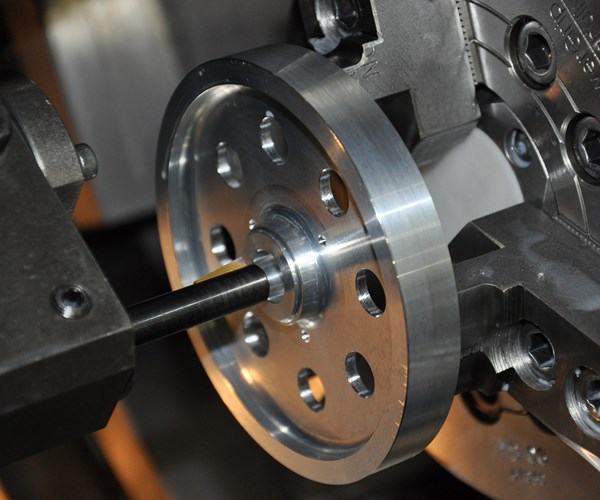

Similarly, whenever a new machine tool is considered, management brings in people who will be directly involved with the equipment to provide feedback. These days, the shop is increasingly adopting equipment that offers the possibility to machine parts complete. Turning centers with live tooling, multiple turrets and multiple spindles can do what once required two or three machines to complete. This greatly reduces setups, part handling and work in process. When multiple machines are needed, some lathes and mills have been paired in cells to minimize part travel.

Mr. Carter notes that machine loading/unloading is the most disliked task on the shop floor. Those on the shop floor also realize that machine tending is the least efficient duty they perform. That’s why they appreciate not only the trend toward multifunction equipment, but also the increasing adoption of automation, Mr. Carter explains. To that end, most lathes in the shop are fitted with bar feeders. There’s also a Doosan Puma LSY-GL gantry-loaded turning center that enables long stretches of unattended operation. Other machines have shop-designed automated loading systems or carousels to collect completed parts. The shop’s latest piece of automation is a robot-tended Mazak Quickturn 250 lathe with a part shelving system to accommodate a variety of jobs. Such automated processes enable the employees to perform more important duties, such as inspection, assembly or parts packing to help speed delivery times for jobs. The processes also enable employees to be focused more on monitoring, tweaking and optimizing machining processes.

In turn, management looks to add equipment that can enable shopfloor employees to be more efficient in their duties. This is especially evident when it comes to speeding and simplifying part inspection and statistical process control (SPC) tracking, which is becoming increasingly important. Here are a few examples.

• Knowledge-based SPC—An increasing number of Rable Machine’s customers are calling for SPC tracking. Previously, that meant operators had to be mindful about how often part measurement was required and diligent about logging inspection data using a conventional paper-based system. Each part had an accompanying inspection control plan, which included information such as dimensions, tolerances and measurement tools to be used to determine particular dimensions. Depending on part complexity, these inspection control plans could contain 10 documents. In addition, operators had to keep an eye on any part features that were trending out of tolerance and make machine adjustments, such as changing offsets or replacing a worn tool.

To simplify these efforts, the shop began implementing the Micronite knowledge-based SPC system from High Tech Research (Deerfield, Illinois). This system allows operators to quickly enter dimensions without wading through multiple pages of an inspection control plan. Plus, the system keeps track of the frequency of the checks, prompts operators when inspection is required and identifies the tool path that controls each dimension. When a feature is starting to drift out of tolerance, the system will issue a warning and ultimately issue a stop alert to signal the operator to bring the process back under control.

The system also prevents operator over-management. Rather than allowing a cutter to experience normal, expected wear, some operators try to stay perfectly in the middle of the tolerance band. Such over-management can result in not using all the available tool life as well as additional machine downtime for frequent adjustments.

There are currently five workstations in the shop running the Micronite software, and the shop plans to install five more. Because moving away from paper-based SPC procedures represented a major change for the shop, 30 employees were actively involved early in the evaluation process.

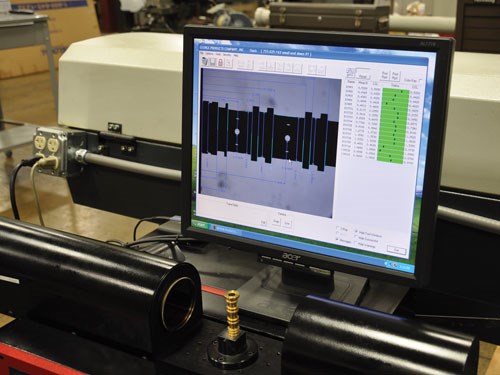

• Non-contact inspection—To simplify measurement of small parts, the shop purchased an OASIS optical profile inspection system from Micro Quality Corporation (Boca Raton, Florida), which can measure multiple part dimensions simultaneously and instantly. The system creates a shadow image of the part on a computer screen and automatically measures every dimension to an accuracy of ±0.0001 inch. An inspection program created for each job includes the dimensions to measure with requisite tolerances. Measurements are instantly compared against process limits, and the system provides operators with a graphic display of feature measurements in relation to the tolerance band. Operators know immediately if a good part has been produced.

This system is tied into the Micronite system for easy SPC data transfer. For now, the shop has one OASIS device that is installed on a cart so it can be located wherever needed. Most machine tools have electrical outlets attached to them to provide power to the device.

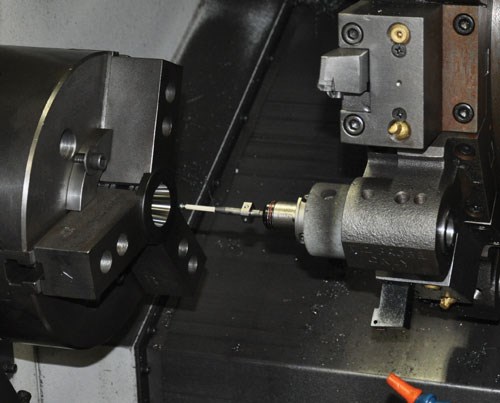

• On-machine probing—Most machines the shop purchases these days include a touch-trigger probe to enable in-process inspection for part features with exceptionally close tolerances. The probes automatically signal the machine control to make offsets based on the measurements it takes, and will prompt an alarm if a feature is found to be trending outside of tolerance. The key, Mr. Carter explains, is to choose a few critical dimensions for the probe to measure, not all of them. This minimizes the amount of cutting downtime due to workpiece probing.

Communication is Key

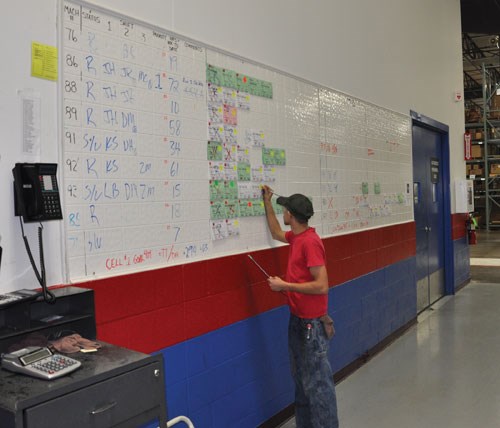

Studies show that productivity and profitability improve after an ESOP has been implemented. The success that Rable Machine has experienced certainly supports that notion. Mr. Carter, who has been involved with ESOP companies since 1986, says the most important aspect of managing an ESOP is maintaining an open line of communication. After all, the employees “own a piece of the rock,” so they are naturally interested in how the company is performing.

Related Content

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreHow to Choose the Correct Fixed-Body Plug Gaging Solution

The two types of fixed-body plug gages are both accurate, fast and easy to use. Consider these factors when selecting one for your gaging application.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)