Share

Rathburn Tool was founded by current company president Angie Holt’s father in 1983. Today, the company has 32 CNC machines (half are lathes and half are milling machines), and works with the heavy truck, rail, fastener, medical furniture, recreation and audio/visual industries.

“I never expected to come and run the family business,” says Angie Holt. “That was never in the plans.” In 2018, Holt became president of Rathburn Tool & Manufacturing, a business her father founded in 1983 to produce small quantities of parts for the heavy truck industry. “Our first location had manual machines on concrete blocks on a gravel floor,” she says. “But he really ramped up the technology very quickly over a short period of time.” The shop had the first non-captive CNC in the area, and was on the leading edge of statistical process control (SPC).

Rathburn was the business Holt grew up around, packaging parts and mopping floors over summers and on the weekends. She left home and spent 20 years in the corporate world, doing finance, operations and project management in the commercial construction industry. In 2018, she returned to Rathburn with the intent to support the business as operations manager, using the skills she’d developed during her time away. “It wasn't until I got here and we sat down as a family that I realized we needed to make a serious change,” she explains. By the time Holt joined Rathburn, her father had been retired for 10 years and the company’s growth had slowed under the interim leadership. Now, as the company’s president, she has overseen a number of changes that have diversified the company’s capabilities and customer base, transforming the business from stagnant to successful.

When Holt joined Rathburn and refocused the company’s strategy, Swiss-type machining was a natural fit. The company had been considering this capability for years — in fact, engineering manager Brian Cole keeps a “wish list” of machines based on the jobs he quotes, and Swiss-types were at the top of the list.

Swiss on the List

One major change Holt has made is building more flexibility to deliver high-quality batch production work. Rathburn has a few dedicated cells that run continuous production, but now the focus is on growing the batch work. A batch could range from 50 to 5,000 parts, depending on the design, industry and machine. “We’re targeting technology to suit that — to be able to set machines up and turn them with the expectation that those are going to be repeat orders,” Holt explains. The shop has added several new machines since 2019 in support of this work, most of which has been turning equipment.

This is part of Rathburn’s larger strategy to diversify into new end markets. “Too much of our work was dedicated in too limited of an area,” Holt says. Her plan also included hiring a technical sales representative to pursue new work for the business. The new work, in turn, helps determine which new technology the shop invests in. Rathburn’s engineering manager, Brian Cole, keeps a wish list of new machines based on the jobs he quotes, and will quote jobs with the shop’s existing equipment as well as machines on his wish list. Holt then uses this information to decide where to grow the business. “As we look at the quotes, we can ask, why did we miss that? What kind of machine would make us more productive? Could we produce that at the same or better quality, better throughput, or be able to offer it at a cheaper rate?” she says. One capability that kept appearing on the wish list was Swiss-type machining. When Holt joined the company and realigned its strategic goals, Swiss machining was a natural fit. So in 2019, the company purchased a used Citizen Swiss A32.

“As we look at the quotes, we can ask, why did we miss that? What kind of machine would make us more productive? Could we produce that at the same or better quality, better throughput, or be able to offer it at a cheaper rate?”

This rail industry part was the first job Rathburn ran on its Swiss-type machine. It was a recurring job that it had previously been making from hexagonal stock on its chucker lathes; using a Swiss-type allows the use of round barstock, reduced three setups to one, improved part quality and enables more unattended machining.

The first job Rathburn ran across the Swiss-type was a recurring job that it had previously been making on its regular chucker lathes. The part, which is for the rail industry, has a hexagonal feature, and thus required hexagonal stock on the chucker lathes. Moving it to a Swiss-type machine enables the use of round barstock, reduces three setups to one, has improved part quality and enables the shop to run more unattended. These factors have allowed the shop to reduce the price it charges the customer by 20%. The shop has since found additional Swiss-type work in industries including fastener, medical furniture, recreation and audio/visual equipment, and added two more Citizen L32s.

The shop upgraded one of the L32s with a flexible guide bushing from JBS. The system uses air pressure, enabling it to adjust to uneven extruded barstock. Holt says that lead times for ground and polished aluminum barstock have been as long as six-to-eight weeks recently, and it’s more expensive. But flexible guide bushing allows the shop to use unground stock, which saves time and money. Because Rathburn does batch work, which isn’t as predictable as production work, it doesn’t want to hold several different types of bar stock in inventory — a key reason why the shop tries to get things off the shelf as much as possible to save time and money. “It allows us to be more reactive to the batch orders,” she notes. This feature has proved so helpful that the shop is planning to upgrade its other two Swiss-types with the same system.

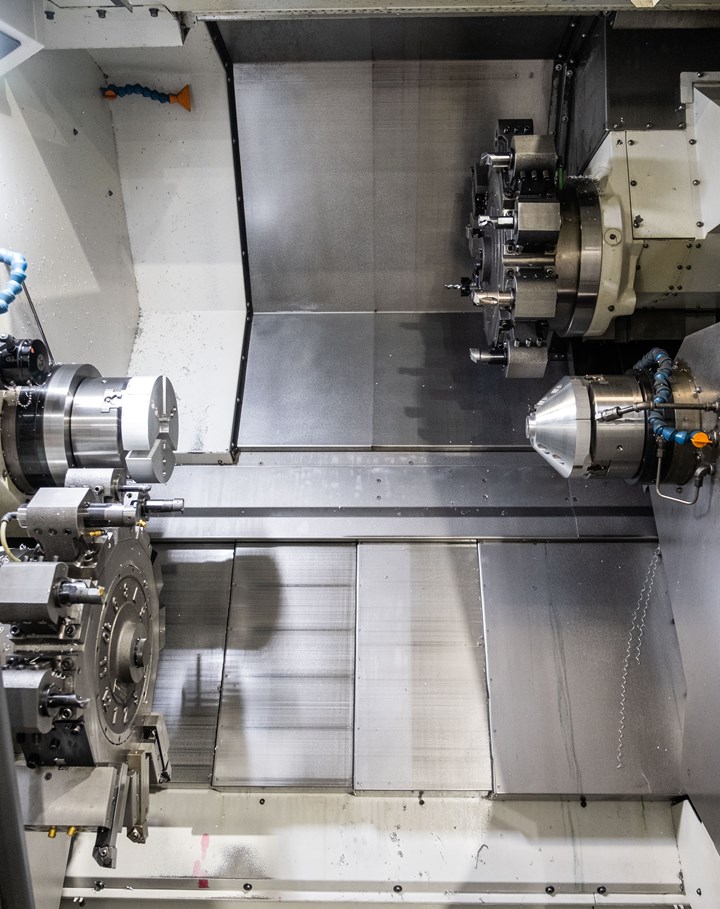

Another technology Rathburn had been considering for years was live tooling lathes. The shop now has two, this Takisawa TM-4000Y2 twin-spindle, twin-turret lathe (nicknamed “the Beast”), and a Takisawa TS-4000YS twin-spindle, single-turret lathe (“Baby Shark”) that, for the right jobs, can improve throughout and allow more unattended machining.

Feeding the Beast

Another capability that was on the wish list was live tooling lathes. In fact, Holt considered adding live-tooling lathes early on in her tenure. Her first equipment purchase as company president in 2019 was two “beefy” Takisawa TCN-2600L6 chucker lathes with box guideways, which were meant to replace two of the shop’s older chucker lathes. “After we bought them, I thought, was that really the right decision?” she says. “Should we have gotten live tooling? Should we be looking at something different?” Eventually, she realized that a lot of the work running across these lathes either had no milling, or required very heavy milling. The live tooling was obviously no benefit to parts that required no milling, and the parts with heavy milling were best suited to a two-operation process. The cycle time on a live tooling lathe would be too long, and the machines just aren’t designed for heavy milling. “It actually was a solid purchase,” she says. “I think it's suited us well and I'm glad we have them. They stay pretty busy.”

As the shop continued to acquire new customers, it eventually did add live-tooling lathes — a Takisawa TM-4000Y2 twin-spindle, twin-turret lathe (which the shop has dubbed “the Beast”) and a Takisawa TS-4000YS twin-spindle, single-turret lathe (known at Rathburn as “Baby Shark”). The shop added its first live-tooling lathe, the Beast, for a repeat order for a part that seemed to be a good fit. In the end, that part didn’t end up running on the new machine, but it did enable the shop to win new work from a longtime customer. “Even though the original reason for moving to purchase the machine didn't work out, the fact that we'd seen a lot of work that would be a good fit for it was the reason it ultimately did pan out,” Holt notes.

The key to working with live tooling lathes is finding parts like these, with the right balance of turning and milling work. Live tooling has no benefit to parts with no milling work, but parts with too much milling work aren’t right either — the cycle times would be too long, and the machines aren’t designed for heavy milling.

One adjustment the shop has had to make with the live tooling lathes was learning which parts are best suited for them, and which parts are best suited for chucker lathes with additional setups on a milling machine. Cole says that when making this decision, he first looks at whether a part’s tolerances match the shop’s capabilities. Next, he determines which machines (or combination of machines) can be used to make the part. Then he looks at timing (and which machines are open within that timeline), as well as quality and ability to run unattended before determining which process to use.

Ultimately, the shop has found parts with the right balance of turning and milling for its live tooling lathes. One example comes from a new customer that makes fire safety equipment such as fire hose fittings. Some of the connectors Rathburn makes for this customer have threads and holes with tolerances that need to be held to another edge, so machining them in one setup on a live tooling lathe helps with part quality as well as throughput and unattended machining.

The Wish List Grows

As Rathburn grows and diversifies, so does its wish list. The company is currently considering a vertical lathe, which would be allow the shop to handle larger turned parts, as well as a twin spindle single-turret Miyano BNX model that can machine parts on the main spindle and the subspindle at the same time. The Miyano still requires chucking the parts, but the simultaneous machining on the two spindles would increase throughput over its Takisawa chucker lathes.

As with all of the decisions that Holt has made since joining Rathburn, she’ll count on input from her employees to guide her as she translates her business experience into the manufacturing industry. “There's so much I'm still learning every day in order to lead competently and wisely,” she says. “And so I rely on my team help me in those areas where I'm lacking, and I'm learning as I go.”

Related Content

Facilitating Lean Manufacturing Through Modularity

Knowing how to subdivide machines and jobs has enabled Danobat to create a lean manufacturing process that improves its lead times by up to 25%.

Read MoreTop Shops: Designing a Shop to Meet Customer Needs

Working closely with customers and making careful investments has enabled this Wisconsin machine shop to tackle difficult jobs with tight deadlines as a core part of its business.

Read MoreCustom Motorcycle Parts Made Here: Video Tour of a Family-Owned CNC Machine Shop

Lee Wimmer invited us to tour his second-generation family-owned machine shop in Perkasie, PA. This video explores the production processes behind precision-machined parts for both Wimmer Custom Cycle and LS Wimmer Machine Co., and shows how ingenuity and determination are still at the heart of American manufacturing. Today, both companies are now managed by Wimmer’s three sons.

Read More3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

Read MoreRead Next

When a Lathe With Live Tooling Rivals a Multitasking Machine

This shop is working its way up to a full-fledged B-axis multitasking machine. Meanwhile, turning centers with a Y-axis and live tooling are doing just fine.

Read MoreHow to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.

Read MoreWhen Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read More

.jpg;maxWidth=300;quality=90)