Share

When diversifying the shop’s customer list, Kaci King looked to her own interests for inspiration. A fascination with space has led to spaceflight customers, just as a family history of military service has led Kaci to pursue — and win — defense contracts.

When creating custom tooling, clarity of purpose is as important as flexibility of planning. The West Ohio Tool Company, a second-generation custom cutting tool manufacturer based out of Russells Point, Ohio, learned this lesson during a leadership transition in early 2020 and has thrived since. CEO Kaci King even says that the company is on track for its largest year ever in terms of sales in 2023.

Finding Traction

Kaci had performed financial and accounting duties for West Ohio Tool for just over two decades when her father, the company’s founder, had a stroke in late 2019. As he stepped back (reluctantly), she began to take on more of his duties. By early 2020, she was officially CEO, with her husband Rea coming on as president to help fulfill some of Kaci’s father’s duties.

Neither Kaci nor Rea has much experience running machine tools. But familiarity with the company helped them get started, as did Gino Wickman’s Traction: Get a Grip on Your Business, a book Kaci and her father encountered early during the transition. “I had never read a book so full of tools that I felt like I could open the toolbox and be able to start using and implementing them,” Kaci says.

The book detailed the importance of developing core values on the leadership team and building a business around those values. This led to the Kings enumerating six core values for West Ohio Tool:

- Do the right thing always

- Exceed expectations

- Grow or die

- Embrace and drive change for leading-edge innovation

- Together, everyone achieves more

- Focus on the impact/results

But just as Kaci began preparing to put these core values into action, COVID-19 struck. As a tooling company largely serving automotive, the near-overnight shutdown in the industry hit West Ohio Tool hard.

“I read an interview in Inc. Magazine with a woman who basically stated the quickest way to grow your business is to do something at least once a year that absolutely terrifies you,” King says. “And I said to my husband, if we get through this, we are going to grow this thing because we’ve been more scared now than we’ve ever been.”

Careful management carried the company through the pandemic, and the Kings began to carry out their culture shift within West Ohio Tool.

“I feel like the two biggest pieces of the pie are people and processes,” King says. “Because when those things fall into place, the data takes care of itself.”

Success and Succession

Difficulties stemmed from friction between Kaci and the three-person team her father had been building as potential successors. This team had gained a lot of authority over the shop floor over the years, but Kaci and her father had realized the company’s client list was shrinking disastrously under their guidance. Even before the initial leadership transition, the two had discovered that, under the succession team, West Ohio Tool was only targeting repeat business.

The client list had shrunk to one page, and only 0.5% of quotes were captured to become new orders. This attitude also extended to monitoring machines for efficiency, with the team only looking into process issues if job travelers reported efficiency percentages below 50%, as well as customer focus, with King estimating that the shop’s client list was between 95% and 98% automotive at one point.

“Our team became very reactive, not proactive, in a lot of places that needed daily looking at,” King says.

To counter these issues, the Kings embarked on a two-pronged approach: implementing the six core values they had developed, and following a plan Traction called RPRS (or, “Right Person, Right Seat”). While the core values shaped a general philosophy for the shop, RPRS called for the adjustment of roles to ensure people were in the job best suited for their talents. “When the right person is in the wrong seat, people argue,” King says. For the few employees who needed to be shifted between departments, their productivity and job satisfaction noticeably improved.

Unfortunately, the former succession team did not take to this new leadership style, with two people leaving in 2020 and the third being let go in early 2022. These departures led to a gap in machining experience on the shop floor, until the Kings found that an experienced service technician they worked with was looking to get back into production. They hired him in March 2021 and swiftly began shoring up their production staff with additional local hires.

But where West Ohio Tool previously hired for experience, it now hired for culture fit. In an even larger change, it advertised less for open positions, and instead headhunted people locally. The new production manager then taught these new hires machining skills.

“I feel like the two biggest pieces of the pie are people and processes,” King says. “Because when those things fall into place, the data takes care of itself.”

West Ohio Tool pairs several machines with robots, but otherwise only runs a single shift, on weekdays only. The company is flexible about starting times, however, and employees clock in any time from 4 A.M. to 10 A.M., leading to 14 staffed hours each day on the shop floor. Image courtesy of West Ohio Tool. This image was part of a staged photo shoot, and does not include customary PPE.

New Business

Thus far, the data seems to agree with King. The client list now fills 3.5 pages. West Ohio Tool is also capturing quotes with much greater frequency — around 40%, rather than 0.5%. Even softer metrics are seeing benefits: the production manager took a vacation around the time of my visit in August 2023, with King saying it was the manager’s first absence since he was hired that the shop didn’t need to call him mid-vacation for his assistance. Even hiring looks good, with no open positions — almost unheard of in the manufacturing world.

As for West Ohio Tool’s client mix, it has seen mild diversification. Automotive is still the company’s top industry, but it only makes up about 70% of its clientele. The rest come from a wide range of industries, including aerospace, defense, semiconductors, healthcare and spaceflight.

To further gain work, West Ohio Tool is implementing AS9100 — a feat which King says has kept the shop on the ball with maintaining its culture. While waiting for the final certification, it has also taken steps to meet the defense industry’s upcoming CMMC requirements. This has involved overhauls of the company’s security and computer systems, and with the installation of security doors, it should be compliant with CMMC level 2.

According to King, this could make the shop one of the first outside parties in Ohio approved for CMMC level 2 certification. As the shop is seeking additional defense (and defense-related automotive) work, this will set West Ohio Tool ahead of its competitors for many defense-related quotes.

West Ohio Tool uses Tool Studio to simulate production of the tools it designs in SolidWorks and ensure the designs are feasible on the company’s equipment. The company also has a proprietary process for reverse engineering tools via SolidWorks. Image courtesy of West Ohio Tool.

Gaining an Edge

“If you say you’re an innovator, you need to have the technology to be able to do it,” King says, and the shop actively tries to use advanced technology to streamline production of increasingly durable tooling. In the first six months of 2023 alone, the shop invested 50% of sales back into equipment. As for what gets bought from year-to-year, the shop can only plan so far ahead. “With custom cutting tools, depending on carbide or PCD or CBN — the breakdown of orders can look so different in January than in June,” she says.

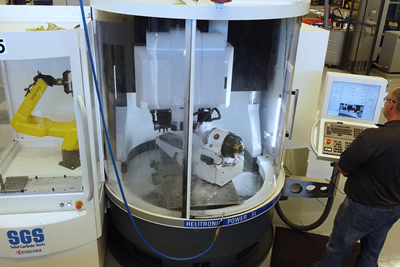

This was the case in 2023, when the shop bought a second Walter Power Helitronic Diamond tool grinding and eroding machine. West Ohio Tool had bought the first in 2017, using the erosion capabilities to produce certain complex geometries and helical features its wire machines could not reach. It also performs better on PCD tooling — an aspect which went from boon to necessity after one automotive transmission manufacturer declared it wanted to move from carbide to PCD, whether or not West Ohio Tool could supply it.

After several experiments, West Ohio Tool developed what it calls the EdgeX4, a carbide tool with an entirely PCD edge. The new tool is more expensive, but boosts tool life from around 25,000 estimated holes and 10 regrinds to well over 1,000,000 holes. In truth, the company still doesn’t know the full tool life of its new tooling — none of its clients using EdgeX4 have reached it.

Early in 2023, a new customer came onboard with West Ohio Tool and mentioned that tooling from this machine was the only tooling it had found that could cut multiple parts and multiple holes in its ceramics. King says the company quickly exploded in importance, with six figures of sales within six months. Plans for other machines had to go on hold however, as resting this entire contract (as well as West Ohio Tool’s entire EdgeX4 line of tools) on a single machine could spell disaster if it was to go down.

As such, the shop pivoted and bought another Walter Helitronic Power Diamond, and plans to replace a handful of manual machines still on the shop floor were pushed back.

West Ohio Tool has also been able to take advantage of Walter’s rebuilding program for some of its old machines. As part of this process, Walter replaces everything but the metal housing. All the electrical connections and axes are new, just housed in the old machine. King says that this process is roughly half the cost of buying an entirely new machine, but can improve job cycle times by 30% to 50%.

Each piece of this puzzle — from machine investment choices to culture shifts — has helped build West Ohio Tool’s ability to service its customers. For now, King’s aims to reach a $10 million sales goal. With 2023 shaping up to be the company’s largest year yet, this goal might not be too far off.

Related Content

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreRead Next

Rebuilding Machine Centers: Low Cost, Higher Performance

By sending its grinding machines out for rebuilding, a tooling manufacturer achieved higher speeds at roughly three-fourths the cost of a new machine.

Read MoreWest Ohio Tool Acquires Women-Owned Business Certifications

The company is now a certified Women-Owned Business Enterprise for the state of Ohio, which expands opportunities in obtaining contracts for goods and services, construction, engineering, IT, professional services and other sectors.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)