Smoothing out the Rough Edges

Surface finishing additively manufactured metal parts.

Share

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreSo, is machining the only way to finish your metal part after additive manufacturing (AM)? You might think so from everything you see and read, but there are countless other post-processing techniques to improve the surface finish and dimensional integrity of your part. Besides, if you have to machine your AM part, you will likely need fixtures and jigs to orient and hold your part, especially if it is a complex organic shape. You will also need to establish datums and references on the part once it is removed from the build plate so that you know how to orient and align it. In short, doing all of this extra work to machine your AM part will quickly undermine all of the benefits and advantages of using AM in the first place.

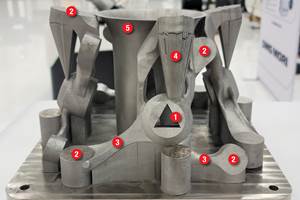

The big challenge with metal AM parts is that they are not “smooth” when they come off the build plate. The close-up of the lattice structure in Figure 1 is a great example of this. Partially melted powder particles adhered to the part, stair-stepping effects of the layer-by-layer process, tessellation of the 3D solid model and differences in up-skin and down-skin surfaces all contribute to surface roughness as I discussed in my October column. Smoothing out these rough edges and surfaces adds time and cost for post processing too and is critical for meeting specifications and tolerances, especially mechanical properties and fatigue life.

As it turns out, there is a host of technologies available for finishing and post processing your AM parts. In fact, it is the same set of technologies that you might use to finish any metal part. AM does not rewrite the rules or redefine the law of physics, nor does it negate the requirements that must be met in order for the part to fly on an airplane or be implanted into someone’s hip, for instance. Tolerances still have to be met, mechanical properties still have to be strong enough and costs need to be competitive, just like any other manufacturing process.

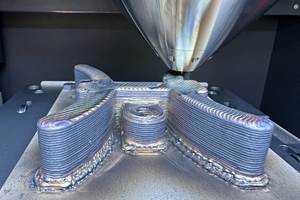

So, what are popular post-processing technologies for AM right now? Media blasting with abrasive materials such as sand, grit and ceramic beads is an easy start and a simple way to reduce surface roughness, but it can be labor-intensive and hard to achieve a uniform and precise finish on the entire part. Likewise, shot peening improves surface finish (see Figure 2), and it has the added benefit of improving the mechanical properties on the part’s surface through the plastic deformation that occurs during the process. Burnishing can also be used to accomplish this in specific regions on an AM part (versus peening the entire part with shot material).

Shot peening is a cold-working process, and companies offer laser peening as an alternative. Interestingly, it is not the thermal effects of the laser that do the work; it is the mechanical effects of the shock wave from the laser pulse that cause plastic deformation and harden the surface. In fact, researchers are starting to combine different lasers into one AM process—use one laser to melt the powder layer-by-layer to fabricate the 3D part and a different laser(s) to do micro-machining and surface finishing. It makes sense to me.

Vibratory finishing, tumbling (barrel finishing, for example) and centrifugal finishing ( harperizing, for example) are also good ways of smoothing out surfaces without needing special jigs or fixtures. Like media blasting and shot peening, these processes work well for finishing external surfaces, but accessing internal surfaces and channels can be challenging. To accomplish this, surface-finishing techniques like abrasive flow machining (e.g., extrude hone) use a viscous fluid containing abrasive particles to deburr and polish internal surfaces and pathways.

Electro-chemical polishing or etching provides an alternative to abrasive polishing. It uses a chemical etchant stimulated by electrical current to smooth and treat the internal and external surfaces of a metal part. The process is relatively inexpensive and controllable, but it requires careful handling of the etchant and waste products.

Polishing and superfinishing processes can also be used to finish metal AM parts. Isotropic superfinishing, for instance, is starting to garner a lot of attention in the AM community given its ability to smooth surfaces and enhance their properties (e.g., corrosion, wear resistance) at the same time.

Related Content

Designing a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read MorePush-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)