Simple Retooling Brings Significant Savings

Changing to Accupro cutting tools from MSC Industrial Supply and adjusting parameters accordingly enabled these shops to realize significant cost savings and productivity gains without fundamentally altering their operations.

Share

Although the old adage “if it ain’t broke, don’t fix it” might make sense in most contexts, this can be poor advice to follow when it comes to manufacturing operations. Even the most efficient processes typically have some room for improvement, and even simple adjustments can impact the bottom line.

Cutting tool distributor MSC Industrial Supply (Melville, New York) says two of its Alabama customers’ recent efforts to boost efficiency exemplify the benefits of constantly striving to improve. At Laser Fabrication & Machine, based in Alexandria, switching from high speed steel (HSS) drills to solid carbide models for drilling bushings reduced cycle times, improved part quality and boosted output levels. Decatur-based Micor Industries realized similar benefits on an aluminum firearm component by switching from standard carbide end mills to cutters coated with zirconium nitride (ZrN).

Laser Fabrication is a family-owned, 50-person shop that provides engineering, prototyping, machining and fabricating services. One of the company’s repeat jobs involves drilling 0.394-inch-diameter holes in 0.75-inch-thick 304 stainless steel bushings that form part of hinge assemblies for buses. Each order typically requires about 2,000 of these assemblies, which the shop splits into lot sizes of about 500 per month to complete the job in six months or less.

Until recently, these holes were produced with standard HSS drills running at 400 rpm and 0.003 ipr. With a cycle time of 2 minutes and 30 seconds, this was a slow process that required pecking at 0.1-inch depths to ensure straightness. The drills typically lasted for 100 to 200 holes before requiring re-sharpening. Unsatisfied with the amount of parts it could complete between sharpening the drills, the shop sought to improve the hole-making operation and reduce overall cycle time for the bushings. “I knew there had to be a better tool for the job, but I didn’t want to spend an astronomical amount of money on a simple drill,” recalls Chuck Thacker, shop supervisor.

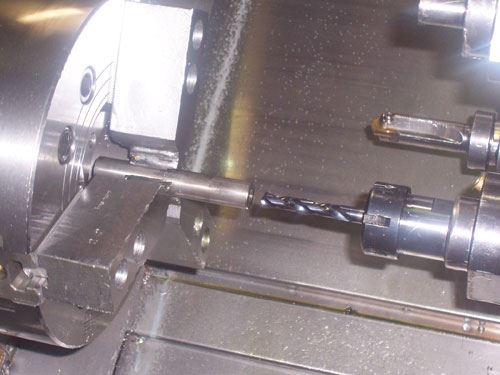

When Mr. Thacker consulted with MSC Industrial Supply about speeding the operation, the distributor suggested using a solid carbide, coolant-fed drill from Accupro. This 140-degree, AlTiN-coated tool features self-centering points and a flute geometry designed for high penetration rates and maximum tool life. With high hardness and wear resistance, it is said to be well-suited for aggressive machining of high-alloy carbon steels; nickel-based, high-temperature alloys; and titanium alloys.

Mr. Thacker admits that during initial test runs, he doubted that the new drills would offer much improvement. He also hesitated because of their slightly higher cost. However, witnessing one Accupro drill complete the work of 10 of the shop’s previous HSS models convinced him that the new tools would quickly pay for themselves. At that rate, tooling cost would remain the same, while overall cost per hole would drop significantly.

Today, the shop can machine about 6,000 bushing holes with each drill before re-sharpening. It can also run at more aggressive parameters of 875 rpm and 0.005 ipr. Cycle time has improved to 56 seconds per hole. Moreover, the solid carbide drills produce straighter holes with better surface finishes than their HSS counterparts, eliminating the need for pecking.

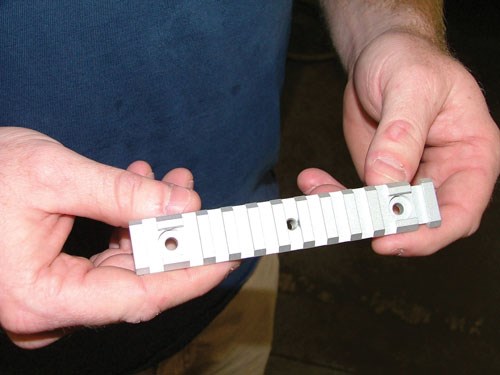

Another MSC customer, Micor Industries, also realized significant productivity and tool life improvements on one job through a simple retooling. This 55-person company specializes in defense, aerospace, oil field and medical work. The problem part was a 6061 P aluminum rail used to mount flashlights, scopes and other accessories onto tactical rifles. Measuring 5.5 inches long by 0.875 inch wide, each rail requires several machined slots. This job usually comes in once every two years in lot sizes of approximately 13,000.

Before the retooling, the shop employed standard, 0.187-inch-diameter, four-flute end mills for roughing and finishing the rails. Each tool typically lasted through about 750 parts before requiring replacement. The shop thought it could do better. “We tried everything for this particular job, but we were maxed out as far as machining feeds and speeds were concerned,” says Justin McMurrain, department lead man at Micor. “Our programmer Jeremy Benderman raised the issue that a different type of cutter might improve rail machining output.”

After evaluating the process, MSC recommended a solid carbide Accupro cutter designed for aluminum, brass, copper and other nonferrous metals. In addition to a ZrN coating that is said to increase lubricity and prevent edge buildup, the tool features vibration-damping cutting edges and a geometry that facilitates high chip loads.

Mr. Benderman worked with MSC sales associate Todd Bickel to test the new tool. Beginning with the same settings employed for the old cutter, they began to progressively increase parameters. Even when speeds and feeds reached levels that taxed the milling machine used to produce the rails, the coated tool never broke.

Today, the shop uses the new end mill to machine the aluminum rails with the same tool paths and cutting depths as the old tool. However, it has increased feed rate by 30 ipm, and it roughs and finishes the rail slots in one pass, as opposed to the multiple passes required with the old tool. Cycle time has decreased as a result. Additionally, the Accupro tool lasts through 2,000 rails without showing any signs of wear. In fact, MSC projected that this simple retooling would provide cost savings of $25,000 on the machine running the rail parts. “Micor’s re-evaluation of its tooling and manufacturing processes is an ongoing activity,” Mr. Bickel concludes. “Any time a supplier can offer a better tool or process, the shop is quick to evaluate and adopt it into its manufacturing operations.”

Related Content

Nidec Universal Head Enables Versatile Machining

The compact universal head enables better accessibility between the tool and the workpiece, as well as improved surface-finish quality, greater motion range and high-efficiency machining under ideal machining conditions.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreBig Daishowa Chuck Eliminates Chatter in Milling Operations

The Mega 12DS chuck is designed for trochoidal milling with anti-vibration end mills.

Read MoreTungaloy Drills, Milling Inserts Provide Enhanced Stability

Tungaloy has expanded its DrillForceMeister and TecMill lines with new drill bodies and milling inserts.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)