Share

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

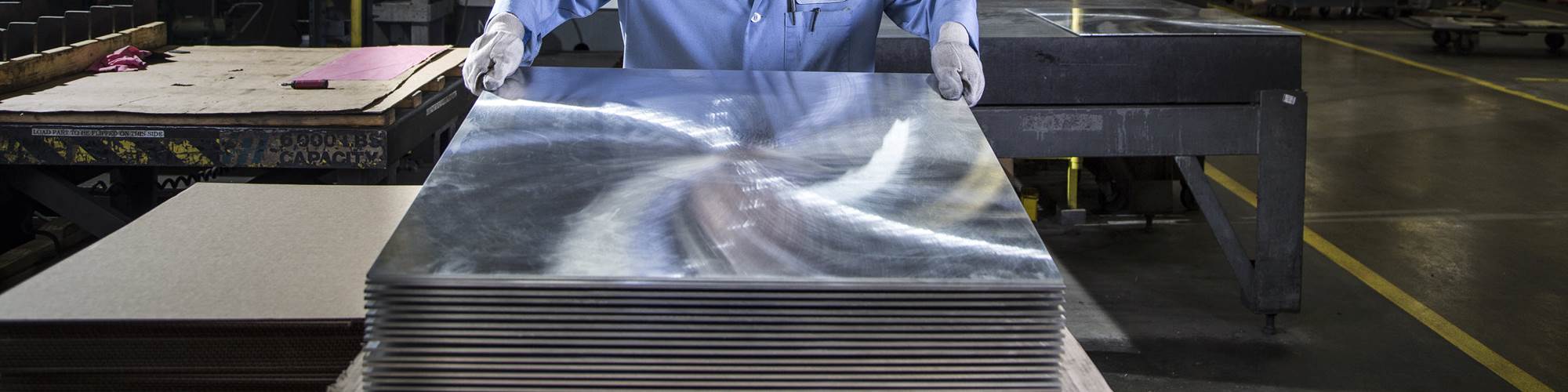

View MoreTCI produces machine-ready blanks to customer specifications within 0.002 inches all around and as close as 0.0005 inches dimensionally, if needed. The company uses a combination of both Blanchard and double-disk grinding, as well as duplex machining. These processes are ideal for achieving the desired tolerance and surface finish while reducing part movement in flat materials. Photo Credit: TCI Precision Metals

For many manufacturers, the first step in a machining operation is to square off the blanks before moving on to machining part features. Keeping the workpieces in a production line as similar as possible is vital, as variances in dimensions can lead to machining errors or automation failures. This is a time-consuming, but necessary process that ensures precision machining can take place. But squaring blanks can also be a bottleneck that demands valuable machining time and slows down throughput.

One solution to avoid this bottleneck is precision blanks machined and ground by a supplier. So we wondered: If machine-ready, precision blanks represent a time-consuming challenge for machine shops, what prevents them from representing the same challenge to a supplier?

To find out, we asked TCI Precision Metals.

Machine-Ready Blanks

TCI Precision Metals is a material supplier that deals in steel, stainless and aluminum — all of which are warehoused at TCI — as well as nickel alloys, tool steel, titanium and plastic on request. While much of its precision blanks are flat, TCI also supplies blanks for prismatic parts. The company uses precision saws and waterjet machines to cut the blanks to a basic shape, then grinds or mills them (in most cases) to a tolerance within 0.002 inches or tighter all around, including flatness. Additionally, the company can hold dimensional tolerances as tight as 0.0005 inches. “Our shop is designed to efficiently produce square, flat material at tight tolerances pre-machined to customer specifications,” says President and COO Ben Belzer. Machine-ready blanks arrive ready to go directly from receiving to machining.

TCI has an array of Blanchard and double-disk grinding machines, as well as duplex mills. The company chose these machines because they can easily achieve the required tolerance while minimizing stress on the parts. Once the blanks are cut or ground to final tolerance, TCI deburrs them and measures to ensure tolerance, employing portable CMMs as well as feeler gauges to check flatness. Additionally, the company can coordinate heat treatment and and coating of parts according to customer needs.

To manufacture its precision blanks, the company first saws raw material to an oversized stock (left), then grinds or machines that material to within 0.002-inches in thickness and 0.0005 inches dimensionally (center). Finally, the company passes the parts off to customers for final machining (right). Photo Credit: TCI Precision Metals

Belzer sees TCI’s niche as simplifying the production process for high-production milling work, especially in automated machining cells. “The more machining time a shop has dedicated to prepping parts,” he says, “the better our value offer is.” By switching to precision blanks, he argues shops with machines dedicated to prepping work can dramatically increase throughput.

Heavily automated machine cells can see especially good results. Robot and cobot arms rely on workpieces being precisely the same shape to reliably transport each part into the machine. Precision blanks guarantee that the parts are within the required specifications without any prep work on the part of the shop. “We see a lot of success with lights-out machining,” Belzer says. “When you set up a lights-out cell, you want to reduce variance as much as possible, and precision blanks can do that without adding any more work for the shop.”

High-Production, Low Automation

TCI performs most of its grinding operations using machine tools older than most of its workers. “Some of our best machines are over 50 years old,” Belzer says. “We have updated them with CNC technology, and they are very good at what they do.” The company has to keep these machines running in excellent shape, as replacements are not readily available. Not many companies make custom grinding machines large enough for TCI’s purposes, which means using older, well-maintained machines that can still reliably hit their 0.002-inch goal.

Meeting that 0.002-inch tolerance is vital for TCI. “We chose that tolerance because our machines can hit it easily, but also because it’s more than enough for our customers,” Belzer says. “At that tolerance, you can avoid any prep work before machining. Photo Credit: TCI Precision Metals

“Our most important area of expertise is in producing flat blanks, especially thin ones less than 0.5 inches thick,” Belzer says. With thicker workpieces, stresses in a small area are unlikely to cause a crack or deformation along the entire part, but flat parts are a different story. Internal material stress built up from the forging process can cause parts to bend or bow like a potato chip during finish machining, resulting in parts being scrapped. Deformation is most prevalent with thin parts with larger surface areas, as the width can provide stressed sections with leverage, while the thickness means there is less mass to resist movement. As part of the production process, machine-ready blanks are stress relieved to help prevent movement.

Belzer says that there are two major benefits to using a double-disk grinder when producing precision blanks: the ability to grind both the top and bottom at once — a process that helps reduce residual stress in the material. “Double-disk is just that,” Belzer explains. “The material floats between two grinding discs with material removed from the top and bottom equally.” The process releases material stress during the grinding process, resulting in a material that is flat and — because the stress has been released intentionally — has a propensity to stay flat.

The Blanchard grinders are primarily used for flat blanks that are too wide for double-disk grinding. For these large parts, the company uses vacuum workholding developed in-house to prevent deformation on especially thin blanks and to allow grinding access to 100% of the surface. The raw material for TCI’s blanks can exceed 120 pounds per piece — or even over 1,000 pounds — providing a significant downward force that helps keep the workpieces in place. The Blanchard grinders are suited for this task because they have large abrasive surfaces that can quickly achieve the desired flatness over a large area. However, unlike the double-disk grinders, blanks machined on a Blanchard require separate setups for each flat surface.

Somewhat ironically for a process that helps shops automate production, the grinding process at TCI is not heavily automated. While the company produces tens of thousands of blanks per month, it relies on the experience of its employees to maintain production levels. The machinists and grinding specialists at TCI need to be experts in identifying which machines are best for which parts, as well as knowing the grit and feed rate required.

Dovetailing Into Milling

In addition to its grinding machines, TCI uses duplex mills for machining prismatic, six-sided blanks. For example, the company uses an Amada THV800 for machining large prismatic blanks up to 31 inches in length and width, and 9 inches thick. The machine has a rotary table that enables the company to mill both length and width in a single setup, further improving the speed of production.

“We use the duplex mills because that’s really the fastest way to machine six-sided blanks that are 1 inch or thicker, and the duplexes can easily hit our tolerance,” Belzer says. The company also uses duplex milling to stack multiple, thin, flat blanks and mill them to length and width before surface grinding. “Volume cutting, milling and grinding are efficient and allow us to provide increased value to our customers,” Belzer says.

Blanks with simple features already added can make production run even smoother. Grooves, dovetails and other elements that aid in setup are relatively easy for the company to provide and save shops a great deal of spindle time. Photo Credit: TCI Precision Metals

TCI also provides blanks with added features to further assist its customers. “This can be a small feature or a hog-out,” Belzer says, “but lately we are getting a lot of requests for dovetails.”

Dovetail fixturing has become very popular in five-axis machining, and Belzer sees precision blanks becoming more popular in that realm. “It’s really the same value proposition as anywhere else,” he explains. “Do you want an experienced machinist spending valuable time cutting dovetails into the bottom of a workpiece, or do you want them machining complex parts?”

Related Content

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Read MoreManaging Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreUsing the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Read MoreRead Next

Keeping Blanchard Grinding Current

What do you do when a large portion of your business depends on machine tools that are more than 30 years old? You roll up your sleeves and perform some of the maintenance of your machines yourself, even if you are the company’s VP, because that maintenance is crucial to the shop’s success.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)