Share

Listen to Episode 2 here, or visit your favorite podcast platform to subscribe to “Made in the USA.”

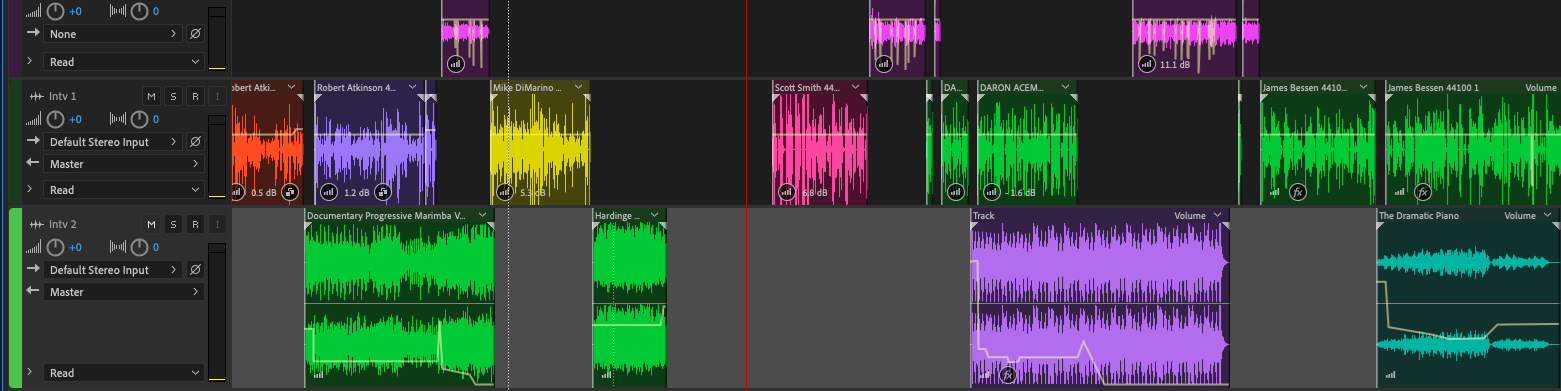

The following is a complete transcript for Episode 2 of the “Made in the USA” podcast. In addition to the hosts, the commentary in this episode is provided by:

- Daron Acemoglu, Economist and Professor, MIT

- Robert Atkinson, President, Information Technology & Innovation Foundation

- James Besson, Professor, Boston University School of Law

- Mike DiMarino, President, Linda Tool

- Rob Ireton, Plant Manager, Plethora

- Scott Smith, Group Leader, Intelligent Machine Tools, Oak Ridge National Laboratory

Brent Donaldson: Welcome to ‘Made in the USA, a podcast that dives deep into the past, present and future of American manufacturing. I’m Brent Donaldson.

Pete Zelinski: I’m Pete Zelinski. And in the last episode we talked about a number of factors that contributed to the decline in manufacturing employment that turned into a plummet in U.S. manufacturing employment for more than a decade starting around the year 2000.

When we look for root causes there, increased reliance on automation is one piece of the puzzle. And in this episode, we are going to talk about that: automation. Last episode, there were reasons why we said, “not so fast,” in response to those who saw automation as the principal explanation for the U.S. manufacturing job declines just after the year 2000. Still, automation played a role — it would be incorrect to say that advances in automation don’t affect employment levels. But there’s an even more fundamental question that I think we need to answer when we talk about automation, and that question is: to what extent is automation an answer to the skilled workforce shortage, and to what extent is automation vs. Skilled labor the wrong comparison to make in the first place?

Brent Donaldson: Exactly. When a company opens a new manufacturing plant or expands an existing one, we rightly celebrate the jobs it will create. But ultimately, and this sounds awful to even say, but ultimately are jobs the point? When it comes to the health and welfare of our economy and our people, are jobs the ultimate goal?

On one hand, the answer is yes. It is perfectly valid to say that the priority in manufacturing or any other industry is to protect jobs. And if you believe that, then you might also believe that automation, and let’s stick with manufacturing here, so… machine tools that run unsupervised, software automation, robots that automate certain tasks — if you are a person who believes that at the end of the day our industrial sectors have a sacred obligation to provide and protect jobs, then you will look at lights-out machining as technology and think maybe that’s cool tech but it’s also scary, right? There used to be a person who ran that machine tool overnight, and now that person is no longer needed.

Pete Zelinski: But the other side of that example is that, because the machine shop automated and innovated a way to produce more parts with less people, that shop gets to keep producing. Its customer isn’t looking for a cheaper solution because the shop is using technology to produce more. And now that shop keeps the contract, pays its employees and maybe even grow its business. Lights-out machining keeps the lights on.

So we are going to talk about automation — its meaning for manufacturing, its meaning for our workforce, and we want to warn you now that automation is a complicated topic with parallel truths that exist at once. But let’s start with a simple one, a simple truth: people have been automating for so long that we rarely think about the automation we use in our daily lives, like washing machines, cars, microwaves, automatic bill paying from your checking account, or even a hand cart…

Scott Smith, Oak Ridge National Laboratory: A lot of people think the robots are coming to take their jobs, right.

Pete Zelinski: This is Scott Smith, who you might remember from the first episode. He’s the group leader for machining and machine tool research at Oak Ridge National Naboratory.

Scott Smith: And there's a lot of articles that are written with that sort of a theme in it, we're afraid of robots, we're going to lose our jobs. But we're not afraid of hand trucks for example. Right? One person with a hand truck can carry a lot more boxes than one person without a hand truck. So, think of all the jobs that were lost because we bought those hand trucks. But nobody suggests that we go back and just have people carry boxes. We're more productive with the hand trucks. So the argument that I'm making is about increasing the production We have to get more productive. That's the way that I see it. So, how do we do that? What's the what's the strategy in a high-wage country? Okay, so we have to innovate.

Pete Zelinski: Scott goes from hand carts to machine tools, and we need a definition here. As we described in the last episode, machine tools are the machines that make machines. They are a technology Brent and I know well — we write about them for Modern Machine Shop magazine. At the same time, talking about manufacturing means talking about machine tools. They are arguably at the foundation of the manufacturing economy, and they are some of the most important representatives of manufacturing automation.

Scott Smith: So if I think about machine tools, when I'm putting machine tools in a high wage country, well, they have to be highly automated, right? And in a low wage country, you have a you have an operator at every machine and the machine doesn't have very much in the way of automation because you can't afford that. But you've got lots of people there and you're not paying them very much. So if you need more things, you buy more machines, and you have more people standing next to those machines. And you just copy that over and over and over. In high wage countries, you can't do that. In high wage country, you have to figure out a way for one person to produce more things. So in high wage country, you have palletized systems. You have robots who are loading parts on the pallets or people who are loading parts on the pallets.

Brent Donaldson: Economist Robert Atkinson gets a bit more into the weeds on this point.

Robert Atkinson, Information Technology and Innovation Foundation: What you see is manufacturing, jobs have grown somewhat since early 2012, 2013. But you have to understand the reason manufacturing jobs are growing — it's just very troubling and hardly anybody's talking about this. For the first time, again, probably in American history, U.S. manufacturing productivity, measured as output for our work, is actually growing more slowly than services. And that's one of the reasons why we're seeing manufacturing job growth — because you're not automating. Manufacturers aren't automating as much as they should be. And that to me is a big serious long-term problem, because while in the short run, yeah, sure, we can create some jobs there. As the overall economy expands, companies get more work, more machine tool work, more machining, so they have to add a couple more workers. That's fine in the short run. But in the medium term, if you can't raise your productivity, you lose price competitiveness in global markets. And so I really worry that —and I’m not saying it's going to happen — but I worry that unless we turn that around, the next big challenge will be how do we be more competitive with places like Mexico, or places like Germany, or places like China or India? You know, we, U.S. manufacturers, we can't compete on low costs. We want to compete good wages, good living standards. But the only way to do that is you have to raise productivity and you have to keep innovating.

Pete Zelinski: So the argument here is how increased productivity is the only way we can compete with low-wage countries. What’s productivity? The amount of output per person, using technology to let each person drive more output. But the topic is about more than that. Sometimes it means doing more with the same amount of space. This is especially true in places where space is at a premium, like New York City.

Mike DiMarino, president, Linda Tool: So I have some automation here. And I was looking at very sophisticated automation until (the pandemic) unfolded here because I needed it to produce. So in New York, for me, people say me all you need to expand, you’re so jammed up in here, why don’t you buy another building? I say, listen, with the way New York is, if I buy another building, I'm not going to put machines in it, I'm gonna put a condominium or a co-op on it, and sell it and sit on the beach and collect money every week, you know? So in order for me to expand here, I've over the past 10 or 12 years, I’ve gotten rid of older technology machines, CNC machines, and brought in machines where one machine can take the place of three. So I brought in mill-turns, I brought in a gantry motor, I brought in five-axis. So that allowed me to expand, but not on a real estate footprint.

Brent Donaldson: That’s Mike DiMarino, who you might remember from the first episode. Incidentally, Pete, you and I have been in Mike’s shop in Brooklyn and he’s not kidding when he says he takes advantage of every square foot of that space. He’s even got a rooftop garden where he grows herbs and flowers and several unusual varieties of tomatoes.

At any rate, his arguments are right. He can’t expand his footprint, and he’s limited to how many employees he can fit in his current space. So, growing the business means increasing productivity with the employees that he has. But obviously, he still needs people. I think we need to be careful not to confuse automation with automatic. People need to program those CNC machines to design the parts, to run measurements and do QC. So at some point you have to ask: even if he had room to grow, would he hire more people?

Scott Smith: So if you look in a highly automated system, there's a lot more machines than there are shop floor workers. One person on floor runs a lot of different machines. But all together, there's a lot more people than there are machines because it created all kinds of new jobs to do that. So you have the NC programmers, the process planners and all that kind of stuff. The workers, you know, they're supervisors rather than operators. A lot of people when they talk about the loss of the jobs, they have in their mind the people who put the workpiece in the machine and push the button. But I think you've got to look at all the jobs, right?

Pete Zelinski: So there it is. You have to look at all of the jobs. And economists have done that. Or tried to. And let’s accept that as a nation, we’re more competitive in manufacturing if we embrace automation. But there are costs, and we have to be real about that, too, and those costs are not distributed evenly throughout the country. At the regional level, in communities that benefit from manufacturing plants, it is at best a mixed blessing – and maybe a net loss – if those plants advance into greater automation.

Daron Acemoglu, economist and professor, MIT: You know, what automation does is that it substitutes capital for labor.

Pete Zelinski: This is Daron Acemoglu, professor of economics at MIT.

Daron Acemoglu: And that's why (automation) is such a powerful trend, because if you can efficiently use it, capital would be cheaper. And that's why employers find it profitable to use robots, and you see that some of the sectors that have switched to robots, like car manufacturers have increased their productivity substantially. But that means that, you know, capital owners gain to some degree and also this enables, to some extent, cheaper car being manufactured. And what we do is that we use data and estimates from a variety of sources to compute what the impact of this would be on prices and gains for other parts of the economy. And it turns out, you know, those gains are important, but they're not enough to make up for the employment losses that have happened in the areas where manufacturing used to concentrate.

Brent Donaldson: So yes, clearly there are costs associated with automation. He’s not making a value judgement there. We’re better off to some extent having cheaper cars. But there is a cost, and the cost is often localized. The result of that is, ironically, that at the local level some people might hope their manufacturing plants don’t become too technologically advanced.

Pete Zelinski: To be fair, I think plenty of people would have a problem with this line of argument. It seems to suggest we should go slow on automating or not automate at all. It also seems to contradict the world we see. We have jobs in this society, this technologically advanced society. Even during a time when unemployment is high, most people who want a job can have a job, even in a society with lots of automation. We mentioned washing machines as an example of automation. If people don’t have to do their wash by hand, doesn’t this set them free to do more productive work? Doesn’t automation in the end ultimately lead to more jobs? Or better jobs? It seems to. How does this happen?

This gets back to the question we asked earlier: to what extent is automation an answer to the skilled workforce shortage, and to what extent is automation vs. Skilled labor the wrong comparison to make in the first place?

James Besson, Boston University School of Law: Yeah, I think it's the wrong comparison.

Pete Zelinski: This is James Besson, executive director of the technology & policy research initiative at the Boston University School of Law, and someone who writes frequently about automation.

James Besson: Automation can have the effect of increasing the demand for skilled labor I think historically that's often been the case. If you look at something like the textile industry, you know, we think about today the textile industry automation is something that destroys jobs, and employment in textiles has been going down since the late 1940s. In the U.S., part of that is because of global trade, but only the most recent years is that true. But for over 100 years before that automation was accompanied by growing employment in the textile industry, and many other industries as well. You know, it may seem to many people counterintuitive or not even nonsensical, that automation could create more jobs. And in doing so, it often was creating jobs have a higher level of skill or improving the value of skills. So Why was this? How did this happen?

You know, think about textiles. At the time they began automating textiles in the early 19th century. Cloth was extremely expensive, the typical person only had one set of clothing. When automation came along, it reduced the amount of labor needed to produce a yard of cloth. And, but in a competitive market, that meant that the price went down. Well, the price went down, and now all of a sudden, people could afford more cloth. And they bought a whole lot more cloth. In fact, so much more cloth that the number of textile workers increased, even though the labor per yard went down. That that was true for like I said, 100 years, over 100 years. You get to the mid 19, mid 20th century though and all of a sudden people have lots of cloth, you know, they've got full closets. They've got cloth furniture, upholstery, they've got draperies, you know, all sorts of uses of cloth. Automation is still chugging along it's still reducing the relative price of cloth. But demand just doesn't go up that much like it did in the beginning. Demand is become satiated and so, at that point, the labor reducing side of automation takes hold. There seems to be some studies suggesting automation is very closely related to upskilling. You know that they may reduce certain kinds of labor, but there at the same time, they're increasing demand for more skilled workers.

Brent Donaldson: So automation led to an increase in jobs, but only because an expensive product became very cheap and totally changed the market. That’s not happening anymore – textile demand has been stable and employment is no longer growing. So when you talk about automation increasing low-skill jobs, you need a case like that: an expensive product becoming really cheap. Could we get to really cheap cars, really cheap cell phones? The trend lines don’t seem to be moving in that direction.

Meanwhile, it’s not just manual-labor workers like in a textile mill whose work can be displaced by automation. We mentioned software is automation as well. Not just manual work, but also mental work can be automated. Rob Ireton is a plant manager at plethora, another company that does CNC machining. In addition to using automation on the plant floor, this company uses software automation to get the job ready for machining, and that is just as important.

Rob Ireton, Plethora: Most of our automation right now is focused on the software, which as I mentioned earlier, it's the user interface, it is the interaction with the customer on the front end. And then in the background, our proprietary software is doing the analysis of the parts. And then it is moving that information into our programmers, which, we currently have a bank of traditional programmers that take that data, and if it's good to go, they release it to the machine.

We had a study done a couple months ago, and within the $20 billion machining industry, the quick turn R&D focus is $7 to $9 billion of that. And that's where we live. And I think that's one of the reasons why we are expanding is because we have a philosophy of delivering high quality parts in the shortest amount of time possible.

Pete Zelinski: This is weird to say out loud but it’s an important point: thinking takes time. But by automating thinking, this company can run smaller orders faster, deliver them faster, and take on a lot more of this small-order work.

And in this case we are not just talking about button-pushers or low-skill manual laborers. Automation replaces knowledge work as well.

Brent Donaldson: CNC machine tools are a kind of automation. And those machine tools replaced machines that were not automated, at least at some point in the past. But new machine tools are computer controlled — they have to be programmed. Therefore, many machine shops today employ CNC programmers, and that is a type of job that didn’t exist before machining became highly automated. And this goes back to what Scott Smith was saying: the final tally has to include all of the jobs.

Pete Zelinski: I think we’ve arrived at the point where this topic become really complicated. Automation creates new categories of employment. Automation creates jobs. But certain communities lose out from automation. The boom in textiles jobs from automation isn’t likely to happen again. And not only that: we now understand how we can automate certain quote-unquote, thinking jobs.

So which is it? Does automation kill jobs or create them?

And the answer is… yes. Both.

Daron Acemoglu: You know, once you continue the right line of reasoning that I was talking about earlier, you know, automation, robotics would be one part of it. But it's true for, you know, computerized numerical control, numerical control and other types of automation. Also, they substitute capital for workers, but much of that takes place at the lower end of the skill distribution. You're not replacing engineers; you're not even replacing technicians. In fact, many of these automation technologies need more input from technicians, design workers, engineers. So it's really workers, middle-skilled workers and lower-skilled workers, that are being replaced. And that puts pressure on the wages of these workers and tends to contribute to inequality.

Brent Donaldson: If you remember earlier in this episode, Acemoglu said that with automation, capital replaces labor. Or at least, some labor. It also demands other types of labor. And as anyone in manufacturing can attest, there is not enough of supply of this new type of labor. That is a problem. We are building more advanced pieces of automation faster than we can adapt people’s skills to run that automation. Our wages reflect this. People who can program and run this kind of automation are in demand. Thankfully — and this is the point we’ll finish on — there are examples of how we can meet that demand.

Daron Acemoglu: Well, I think it's complicated with skilled workers. We have some other work which shows that for other countries, and this will happen for the U.S. later on also, that are in the midst of rapid demographic change. Automation is a very powerful tool. So if you look at Germany, South Korea, Japan, three of the most rapidly ageing economies, they are facing acute shortages of middle-age workers, and those are the workers that typically focus on blue collar occupations in manufacturing. Without any response from technology, manufacturing in these economies would have been heavily damaged. But Japan, South Korea and Germany have increased their share of international trade in manufacturing. They have continued to make inroads in manufacturing growth. How did they do that? They did that by responding massively to their demographic trends and investing in automation and, in fact, becoming leaders in the technologies of automation in the world.

Now, that's less easy with skills. Because so far, the automation technologies that we have, don't perform the tasks that skilled workers used to perform. So when U.S. workers, we saw US employers complain about lack of skills. They're really asking for workers with high technical capacity, the ability to flexibly switch from one task to the other, some knowledge of engineering. And all of these are tasks that at the moment, machines cannot perform. You know, some people think AI just around the corner is going to start doing what robotics did to middle-skilled blue-collar occupations in manufacturing. That AI is going to do this for higher skilled workers in, you know, finance and accounting and medicine and so on. We'll see about that. I think it's optimistic to think that's just around the corner. But, manufacturing automation is not really is not really going to be able to replace the very trained highly skilled engineering design and technical workers.

Brent Donaldson: So let’s wrap this up. There are high-skill and low-skill employees in manufacturing. Or maybe a better way to say it is high-expertise versus repetitive, even though some of that repetitive work is pretty high-knowledge. But because of this difference, automation actually needs more employees at the higher end.

And Pete, you and I see all the time when we write about machining: The machine shop owner who says he would buy another CNC machine tool if only he could find another skilled machinist or programmer to run it. This is the “skills gap” we talk about all the time. On the one hand, automation displaces and replaces jobs. On the other hand, it needs more jobs. It can’t perform if the right people with the right expertise aren’t there.

Pete Zelinski: Right. At the beginning of this episode, we asked to what extent are jobs sort of “the point” of manufacturing. On one hand the point of manufacturing is to make the stuff that humans want and require.

So… if jobs are not the point of manufacturing, why do we worry so much about how many people are employed in manufacturing? Why does the graph that looks like a literal cliff where jobs plummeted from in the early 2000s concern us?

Clearly, jobs are not beside the point. The issue is more complex than that.

Manufacturing is necessary work, work that to some extent defines the health of a nation, manufacturing is valuable work, including valuable work for people to do, because it is work that directly involves value creation by making objects people want or need. Nd manufacturing is work that, even when it is automated, needs people. We are doing this podcast because manufacturing is worth understanding… because it is worth encouraging. And Americans want our manufacturing to be “Made in the USA” because it’s work we ought to want our country and people in our communities to be doing.

But the commitment to manufacturing means a commitment to preparing people for manufacturing even as we advance manufacturing so every person in it can do more and more. Companies need to be involved in this. The public sector and the school system need to be involved in this. The question that we, as a country, can answer is: will automation harm communities by costing jobs, even though it struggles to deliver its full promise, or will automation thrive because we have the people who are ready to adapt to the new roles able to oversee this automation?

Brent Donaldson: Made in the USA is a production of Modern Machine Shop and published by Gardner Business Media. The series is written and produced by me and by Peter Zelinski. I edit the show.

This podcast was recorded at the historic Herzog Studio, home of the non-profit Cincinnati USA Music Heritage Foundation. Our outro theme song is by The Hiders.

If you enjoyed this episode, please leave us a nice review. If you have comments or questions, email us at madeintheusa@gardnerweb dot com. Or check us out at mmsonline.com/madeintheusapodcast.

For our next episode we wanted to really beat ourselves up and focus on a topic that is easily as complex as automation. So, we’re going sort out the benefits and challenges of keeping production in the United States. A look into our manufacturing supply chains, next time on Made in the USA.

Related Content

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreFour-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Read MoreInvesting in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read MoreTranslating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

Read MoreRead Next

Made in the USA: A New Podcast from Modern Machine Shop

The podcast series explores the current state of American manufacturing.

Read MoreIntroducing Our New Podcast, “Made in the USA”: The Show for This Moment in U.S. Manufacturing

Join us as we talk about jobs, the supply chain, generational transition and other important themes that will shape the way forward for U.S. manufacturing. Hosted by Modern Machine Shop editors Brent Donaldson and me.

Read More

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)