Online Store for EDM Wire Gives Small Shops A Boost

Online ordering of a small number of EDM wire in spools encourages small shops to use premium wire types for faster cuts, better results and overall lower cost.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

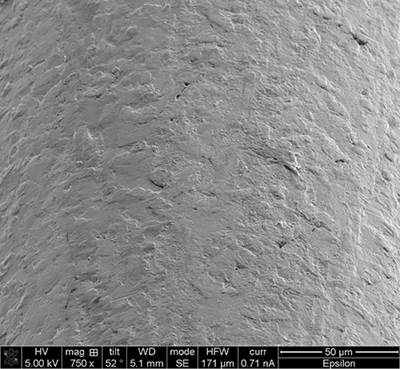

One of the premium wires offered by GIP and available for online purchase is Epsilon Double Coated. It is finished with a second coating of zinc-rich brass designed to improve the wire’s ability to generate exceptionally smooth surfaces in skim cuts while retaining fast-cutting properties in rough cuts through the solid.

Although any company using wire EDM may benefit, Global Innovative Products (GIP) of Mason, Ohio, has a new online method for ordering spools of EDM wire, an option that looks especially promising for smaller shops. These shops are likely to rely on one or several of their wire machines for their flexibility and capability, yet they might not need a large quantity of wire types on hand or maybe they cannot afford to do so. According to Barry Ramsay, GIP’s general manager, these users may not command the best attention from supply houses or EDM consumables dealers that focus on volume sales. As a result, purchasing options for their wire needs can be limited or uncertain, he says, noting that an online store provides an alternative that gives these shops several benefits.

In particular, the benefits he sees for GIP’s approach to online ordering include improved cash flow and liquidity (no need to tie up capital in wire inventory by buying large quantities), access to a variety of wire types (GIP’s offerings range from high-quality, plain brass wire to a number of coated, double-coated and stratified products) and transparent pricing (the dollar amount for each unit is clearly stated, and quantity discounts are applied to all buyers).

However, Mr. Ramsay says that one of the biggest benefits is access to technical information and application recommendations, especially related to using premium wires, which can speed cutting time, give better results, and minimize wire breakage and re-threading problems. Smaller shops, he says, either resist moving to premium wire types because of the perceived learning curve, or the lack of application savvy causes them to miss out on the full productivity advantage of premium wire. “We can provide recommendations for the right settings and machining parameters to unlock the value of premium wire. We also offer technical phone support, enabling a user to talk to an experienced EDM operator who can walk them through any glitches,” he explains. For many customers in the Midwest and East Coast, in-shop consultation is available.

Trevor McCoy, CNC/EDM programmer, runs a FANUC wire EDM with GIP’s Plasma coated brass wire at Clippard, a Cincinnati-based manufacturer of fluid control products. He states that this wire achieves better finish with a 15 to 20% reduction in run time.

GIP works directly with Thermo Compact and Bedra, two leading wire producers, who manufacture wire to GIP’s specifications, many of which are based on exclusive R&D work at the company’s metallurgical labs in Mason, Ohio, Mr. Ramsay says. Currently, the range includes products that are equivalent or superior to about 80% of the most common commercially available wire types. “We can supply wire types that match or exceed the performance of proprietary wires promoted by machine manufacturers. The user doesn’t have to feel locked into using only the builder’s specified brand-name wires,” he adds.

He compares using GIP’s new online service to other popular retail and consumer shopping sites. The wire buyer can create an account or make a purchase as a guest and have the appropriate quantity of wire shipped directly to their shop. Overnight delivery is also available. “Even high-volume users of wire may find this online service convenient and efficient. We can ship product by the pallet if that is what is needed,” he adds.

Related Content

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRead Next

Double-Coated EDM Wire Offers Fast Cutting and Smooth Skim Cuts

An EDM wire with of a second coating of zinc-rich brass improves the wire’s ability to generate exceptionally smooth surfaces in skim cuts while retaining fast-cutting properties in rough cuts through the solid.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)