Double-Coated EDM Wire Offers Fast Cutting and Smooth Skim Cuts

An EDM wire with of a second coating of zinc-rich brass improves the wire’s ability to generate exceptionally smooth surfaces in skim cuts while retaining fast-cutting properties in rough cuts through the solid.

Share

The science behind the wire EDM (electrical discharge machining) process is not always well-understood. For example, misconceptions about the performance of the EDM wire often cause consternation when results are disappointing, despite the fact that these results are consistent with known metallurgical principles.

A new EDM wire product being introduced by Global EDM Supplies Inc. (Mason, Ohio) is based on insights into these principles, says Dan Tomalin, the chief metallurgist who led the development of this wire. Called Epsilon wire, its primary innovation is the addition of a second coating that improves the wire’s ability to generate exceptionally smooth surfaces in skim cuts while retaining fast-cutting properties in rough cuts through the solid, Mr. Tomalin says.

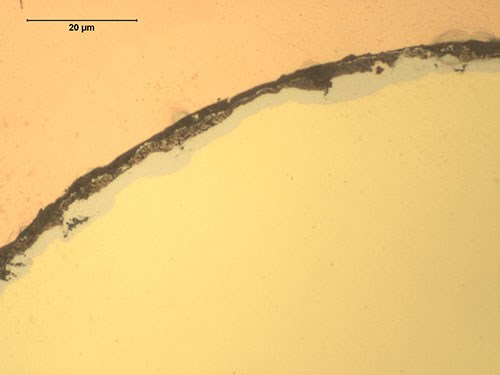

Epsilon wire takes the fast-cutting characteristics of a “gamma-coated” wire, but overcomes the limitations that this type of wire faces in skim cuts by adding a final coating of unalloyed zinc mixed with epsilon-phase brass.

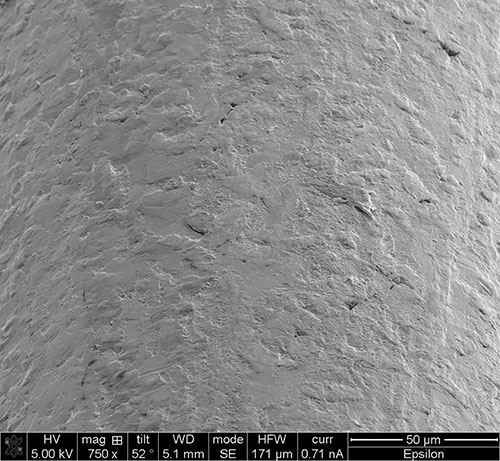

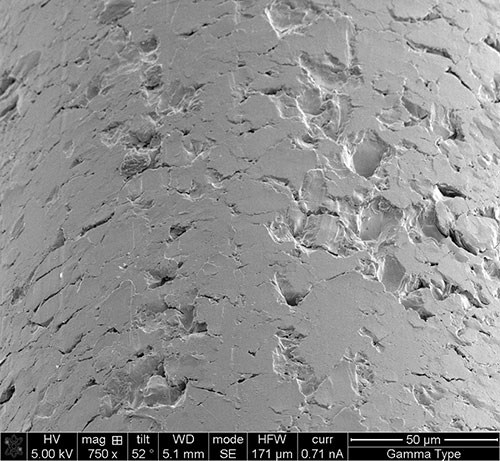

Gamma-coated wires are so called because they are composed of an alpha-phase brass core overlaid with a gamma-phase brass coating. Brass is an alloy of copper and zinc. Gamma-phase brass is the form of this alloy with a very high content of zinc as the alloying element (typically 65 percent zinc by weight compared to 35 percent zinc in the alpha phase). When used as a coating, gamma-phase brass is relatively brittle and must be applied with a manufacturing process that leaves a very thin layer with numerous microscopic fractures. As a result, this coating creates a discontinuous surface, that is, the alpha-phase and the gamma-phase particles leave an uneven concentration of zinc across a pitted texture.

When roughing with gamma-coated wire, the discontinuous surface helps the dielectric fluid flush away the ashy debris created by the EDM process. The pitted texture promotes a turbulent flow of the fluid because the electrical discharges are scattered throughout the stream. In addition, the zinc-rich gamma-phase particles sublimate, that is, they pass from a solid state to a gas in the intense, highly localized heat of the electrical discharges. In a gaseous state, the particles of zinc are extremely small. When quenched by the fluid, these fine particles are easily washed away.

This enhanced flushability enables the gamma wire to withstand a more aggressive level of metal removal by the action of the electrical discharges. In short, it cuts faster. The significant gain in productivity justifies the higher cost of the wire.

However, the flushability of the gamma-phase coating is not helpful in skim cuts. In fact, the properties of this coating are detrimental because the uneven concentration of the zinc content results in irregular discharges that may occur at undesirable energy levels. Skim-cutting, in contrast, relies on uniform, low-energy discharges that selectively remove the unwanted peaks on the workpiece surface.

Here is where the additional coating on the Epsilon wire comes in. This second coating forms an outermost layer with a concentration of zinc that is more uniform than found in the irregular surface of the gamma/alpha structure. When engaged in a roughing mode, the outer epsilon layer is sacrificial. It is quickly “blown away” by the more intense discharges imposed by the higher voltage, thus exposing the same discontinuous discrete particles that enable conventional gamma-coated wire types to achieve superior metal removal rates. Yet, when engaged in skim cutting, the rich and uniform concentration of zinc remains intact at the lower voltage to promote a more efficient smoothing action that leaves a superior finish.

Mr. Tomalin notes that, although double-coating the wire adds to its price, the value of fast roughing and efficient skim cutting with one wire contributes to overall reduced production costs.

Read Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)