Meeting Microgrinding Challenges

A technology for microgrinding reminiscent of Swiss-type machines' sliding headstocks can handle higher length-to-diameter ratios in the grinding of medical guidewires and other long, skinny parts.

Share

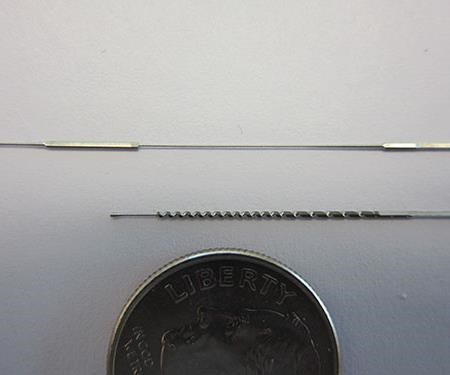

Industries such as medical and dental continue to design components with extremely small features. For example, medical guidewires, which serve as guides for larger devices during angioplasty and other minimally invasive procedures, might call for threads, flats or multiple tapers to be ground on wire as long as 16 feet, but only 0.005-inch in diameter.

Turning’s answer to machining parts with high length-to-diameter ratios is the sliding headstock, the signature feature on Swiss-type lathes. A sliding headstock feeds barstock through a guide bushing and past a tool during an OD turning operation. The guide bushing offers support for the barstock very near the point of the cut, preventing workpiece distortion. This makes Swiss-types particularly effective for turning long, slender parts.

Glebar has developed a similar technique for microgrinding. The Ramsey, New Jersey, manufacturer of OD grinders, centerless grinders, double-disc grinders, and other grinding equipment and accessories offers the CAM.2 machine for grinding medical guidewires (often made of shape-memory alloys such as nickel titanium) and other small-diameter components. This microgrinding machine can accommodate workpiece stock as small as 0.005 inch in diameter and offers a minimum grinding diameter of 0.0005 inch. In addition to guidewires, the machine is well-suited for grinding other cylindrical parts that require tiny features, including dental posts that might call for tapers, threads and grooves.

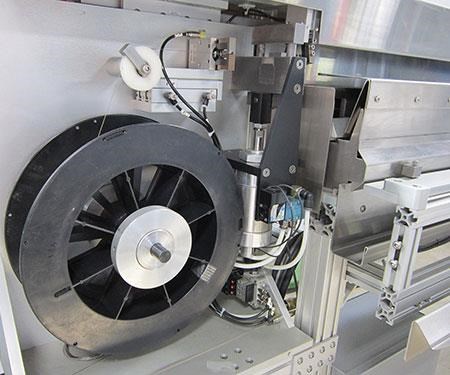

The CAM.2 machine is the next-generation version of the company’s CAM-SXE machine, which was introduced in 2001. The company says the machine platform was developed to address challenges grinding the ODs of parts like guidewires on a conventional centerless grinder. On a centerless grinder, the part is pulled through the machine by the grinding and regulating wheels. To grind a profile, the part’s position is detected by sensors, and the gap between the wheels is adjusted. Instead of applying such a monitor-and-react approach, the new CAM.2 machine uses a dual-carriage, dual-collet linear-motor part-feed system that simultaneously controls wire linear position, linear feed and rotation. This enables the machine to control both the wire diameter and length to a resolution of 0.1 micron.

With this method of OD grinding, the front of the wire feeds through a hydrostatic bushing that uses pressurized oil to enable the wire to accurately float inside the bushing as it spins. The hydrostatic bushing is akin to a Swiss-type’s guide bushing, offering support very near the area of contact between the part and the grinding wheel. As a result, there’s essentially no limit to the length of the wire to be ground. (The CAM.2 machine can also be run in centerless-grinding mode, using a centerless fixture instead of a regulating wheel and work rest insert, simplifying setups and change-overs, the company says.)

Feeding systems are available for individual pre-cut wires or spooled wire. For individual wires, an operator can insert a bundle of wire in the feeding system, and then a vacuum pickup system places individual wires into the feeder. (Feeders can range in size from 3 to 16 feet). Pinch rollers are used to feed a wire to the machine’s two collets. Conversely, the spool system feeds out wire to the appropriate length, and the wire is then tensioned and cut and fed to the collets.

The CAM.2’s grinding wheel spindle power is 3 hp, and wheel speed is variable to a maximum of 3,600 rpm. Grinding wheels are 12 inches in diameter and might range in width from 0.01 to 1 inch, depending on the application. An automatic CNC-controlled diamond-roll dresser is available, which is often a better option compared to a single-point dresser for more advanced CBN and vitrified grinding wheel technology, the company says.

The machine’s CNC has a 15-inch touchscreen and offers 3D visualization of part and wheel shape. Its programming system is conversational, using graphic and menu-driven functions to enable a part program to be completed without G-code knowledge. Among other benefits, this intuitive interface enables one operator to tend multiple machines at once for long stretches of automated operation.

The CAM.2 is available with a number of accessories, including a three-stage recirculating coolant system, wheel balancing system, programmable part extractor, grit blaster and vertical subspindle. In addition, an inline diameter contact gage is available that mounts on the exit side of the machine and measures the ground part. Diameters at several points can be measured, and that data can be used for size compensation and comparison against high and low user-defined limits. The company also offers its new P4K inspection system for small parts. This system uses a precision linear stage that pulls a part through a laser gage, matching diameter and length readings in real time at a rate of 10,000 readings per second. A diameter and length reading is taken every 30 millionths of an inch at a speed of 3 inches per second, and diameter measurement accuracy is ±0.5 micron. The P4K can send diameter measurement to the CAM.2 machine to adjust for wheel degradation by changing the grinding wheel slide position. Similarly, it can send measurement data to correct the wheel dressing profile for infeed applications on the CAM.2 machine as well as the company’s GT-610 centerless grinder. One P4K measuring machine can support as many as seven grinding machines with such feedback capability.

Related Content

Turning Fixed-Body Plug Gages Inside Out

Fixed-body mechanical plug gages provide fast, high-performance measurement for tight-tolerance holes.

Read MoreHow to Choose the Correct Fixed-Body Plug Gaging Solution

The two types of fixed-body plug gages are both accurate, fast and easy to use. Consider these factors when selecting one for your gaging application.

Read MoreThe Many Ways of Measuring Thickness

While it may seem to be a straightforward check, there are many approaches to measuring thickness that are determined by the requirements of the part.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)