Medical Shapes a Shop

Medical job and contract shops face challenges—some unique to the market they serve—that push them to become more efficient. Learn about the efforts this shop has made to clear the hurdles it has encountered along the way.

Share

Machine shops are shaped by their customers, and 3D Medical Manufacturing in Riviera Beach, Fla., validates this idea.

As its name suggests, this successful job shop serves the medical industry exclusively. Specifically, it manufactures implantable components, electromechanical assemblies, and surgical devices and drilling instruments for a variety of medical customers. Customer demands as well as challenges inherent to serving the medical market have influenced not only the equipment that the company has purchased over the years, but also the shopfloor practices and business strategies it has adopted to become more competitive.

During a recent visit, Joe Davis, 3D Medical Manufacturing’s executive vice president, highlighted two tough challenges that today’s medical manufacturing shops face. The first is process validation. In recent years, the U.S. Food and Drug Administration (FDA) has become more proactive in inspecting medical machine shops to validate their machining processes. This takes time and money on the shop’s end. And the inspection goals can be as detailed as ensuring that a CNC machine’s software is performing as it should. (For example, it might be necessary to prove that the M code for turning on a machine’s spindle achieves the correct rpm via testing with a tachometer.) In fact, re-validation is necessary even if a machine is moved a few feet to a new location in a facility.

The medical OEMs are feeling the same pressure. That’s why once a machining and manufacturing process for a new component is established, it can be very burdensome to make a change to that process and re-validate. This traps medical machine shops inside an innovation paradox. After gaining experience running a job, a shop may find ways to manufacture a component more effectively. Mr. Davis says shops can make small changes without notifying the customer to have the process re-validated, such as small modifications to speeds or feeds, or perhaps using a different grade cutter. However, large changes that might affect the integrity of the part must be re-validated (such as suggesting a new coolant or part-cleaning technique). And because re-validation can be tedious for shops and medical OEMs alike, the OEMs are not apt to consider a process change unless it will result in a significant improvement in cost, time, etc.

The second challenge shops face is pricing competitiveness. The Patient Protection and Affordable Care Act (aka Obamacare) includes a new tax on medical devices; therefore, medical device OEMs are looking for suppliers that offer competitive cost advantages for the parts and assemblies they provide. Whereas years ago OEMs were likely to stick with component suppliers that delivered the requisite quality at a competitive price and on time, today there is more pressure on shops to decrease prices.

Medical devices and components are becoming increasingly complex, so shops clearly require advanced machining equipment to deliver the requisite geometric accuracy and excellent part appearance that medical OEMs demand. However, the challenges of serving the medical industry are spurring shops such as 3D Medical Manufacturing to find other ways to become more competitive.

Medical Experience

3D Medical Manufacturing is led by Joe Davis and his brother Jim Jr. The brothers grew up in the metalworking business, working at their father’s machine shop in the ‘70s as well as at a shop owned by one of his friends. Both brothers received manufacturing engineering degrees and subsequently started their first medical machine shop in 1987. After selling that business, they started 3D Medical Manufacturing in 1994. The business currently has 265 employees and two locations, the Florida operation and a second in New Jersey.

The Davises were early adopters of Swiss-type lathes, and they continue to tap the advantages that this multi-process platform offers. The shop currently has 48 Swiss-type machines from Marubeni Citizen-Cincom as well as five-axis machine tools, wire EDM units and automated CNC grinding machines. However, it also has a wealth of non-machining processes in-house, such as citric and nitric passivation, vacuum heat treating, laser welding, laser marking, media blasting, and shot peening. It has electronics test equipment and a Class 7 clean room for electronics assembly, too.

The shop finds great value in being vertically integrated in this way. Having complete in-house control over these processes ensures it will not have a vendor change a validated process without alerting the shop. In many cases, it can perform the service less expensively, too. In fact, once the price of a contracted service begins to increase, the shop will consider bringing it in-house. For instance, electropolishing and titanium anodizing are likely to be the next processes the shop will add to its in-house repertoire.

Vertical integration is only one way the shop is able to meet the challenge of being a successful supplier to the medical industry. Here are three other ways:

• Setup time reduction. Because the shop’s average lot size is only 340 pieces, it has to be proficient at setups and, in turn, effective at scheduling. By carefully planning job sequence, the shop is able to run like jobs together on a machine to minimize the number of tools that must be changed during a set up. Scheduling also makes best use of the shop’s limited amount of setup personnel, so machines aren’t down for extended periods of time waiting for a setup person to become available.

According to Eddie Peña, vice president of manufacturing, Swiss-type lathes can take more than 7 hours to set up, which is why 3D Medical Manufacturing often holds kaizen events to determine how to streamline setup of those machines. For one recent event, the shop brought a well-rounded team together to study and improve upon the existing process, including Mr. Peña, the CNC Swiss supervisor, Swiss setup machinist, tooling and pre-kitting specialist, and manufacturing engineer.

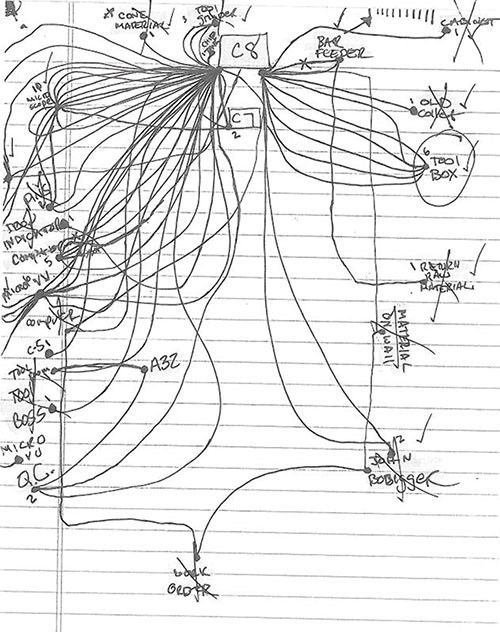

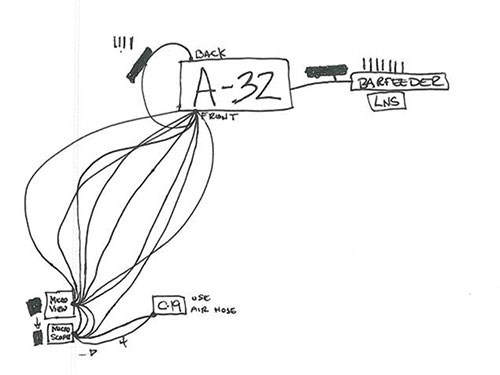

The team analyzed the original set up, which included taking video, in order to document not only every step of the process, but also every physical step a setup person had to take during that process. This led to the development of the complex “spaghetti chart” shown to the left. The spaghetti chart illustrates the setup person’s paths to complete the task. Total time for the original setup was just less than 6 hours, and the setup person walked a total of 5,170 feet. Reviewing and revising this process yielded a faster setup time of 3 hours 41 minutes with only 1,125 feet of walking distance, as illustrated in the other more streamlined and “cleaner” spaghetti chart. One significant change was the addition of job carts to the setup process. Now, all documentation, tools, gaging and any other necessary equipment is pre-configured into carts that are staged for setup personnel to access. A photo of those carts is shown above.

• Tooling control. 3D Medical Manufacturing is currently on its second iteration of a tool vending system, a system from MSC Industrial. This system enables the shop to accurately track every nondurable tool for each job while providing daily tool usage reports for those jobs. This enables tight cost control and ensures that the shop never runs out of the tools it needs, which was a problem in the past that led to extended machine downtime and high next-day shipping charges. The vending system automatically reorders tools once a specified minimum inventory level is reached, and the shop’s tool crib manager reloads the tools when they’re delivered.

However, this system also serves as an important problem-solving device, Mr. Peña notes. He says each job has a maximum number of tools that an operator can pull. The system locks out operators who attempt to pull a tool beyond that limit and notifies a supervisor of the situation. That way, the supervisor can work with the operator to determine why tools are breaking or wearing sooner than expected. In some cases, the operator can precisely explain the problem, meaning a change to the process might be warranted. In other cases, the operator might be unsure of the problem. Therefore, the notification turns into a teachable moment, because the supervisor can help the operator pinpoint the issue and remedy it. The shop also has expanded this concept to its inspection devices, some of which are supplied by customers. This eliminates time wasted looking for special gages, for example, and ensures accountability for those devices.

• Kanban. The kanban inventory system 3D Medical Manufacturing has established for its largest customers was an eye-opener. At the time of my visit, the shop had approximately $4 million in pre-packaged inventory ready to ship to customers in the lot sizes they commonly require.

Mr. Davis explains that this represents an atypical strategy for most shops, but it makes sense for 3D Medical Manufacturing. In the past, customers would have the shop quote small batches to cover their needs over a short time frame (so they would not have to hold too much inventory themselves). This made scheduling challenging because the shop wasn’t sure when an order would be placed and what the lot size would be. Plus, customers that encountered an unforeseen spike in part requirements would place emergency orders that needed to be filled faster than normal, disrupting job sequence.

By maintaining a level of pre-packaged inventory, significant as it is, the shop can more effectively plan work because customers place their orders far in advance. Mr. Davis says the clearer product forecast also enables him to better plan for the addition of new equipment and personnel.

For customers that commit to large orders, the shop agrees to stock an established amount of pre-packaged, finished-parts inventory as well as raw material in cases where special alloys are specified. When inventory levels are reduced to a certain point, a card is pulled and scanned to notify production planners to introduce that job into the schedule.

The key to the success of this system is developing long-term contracts with customers that might run 9, 12 or 16 months. Mr. Davis says the shop develops detailed customer contracts because there are medical OEMs that want to establish this type of relationship with a vendor, but don’t know how to do it. The shop’s contract specifically explains what both parties are committing to so the customer never runs out of the components or assemblies it needs and the shop won’t have to sit on inventory for an extended period of time.

As Mr. Davis notes, it’s all about making customers happy. 3D Medical Manufacturing is willing to carry a high level of inventory to ensure that.

But the shop applies this concept in reverse by setting up similar relationships with its cutting tool suppliers to reduce overall tooling costs. When arranging long-term agreements with those suppliers, the shop also will often ask them to provide value-adding training to employees. In fact, a representative from cutting tool manufacturer Kennametal holds training classes at the shop and even issues diplomas to those who pass the course. Topics covered in these classes include identifying insert failure, determining optimal cutting data and general tooling best practices.

Related Content

Tungaloy-NTK PCD Grade Optimizes Dimensional Accuracy

The DX200 is an effective tool for machining application-specific components that demand high levels of material purity, such as metal medical implants and sputtering targets for semiconductor applications.

Read MoreThe Producto Group Appoints New Member to Board of Directors

Dean Schauer, the newest appointee to the company’s board of directors, is the current CEO and president of Confluent Medical Technologies.

Read MoreEDM, Laser Micromachining and More at GF Medical Demo Center

At GF’s Medical Center of Competence, the company shows off EDM and laser features that could make a large impact on medical manufacturing — and elsewhere.

Read MoreFive-Axis Turnkey Machine Halves Medical Shop’s Cycle Times

Horizontal five-axis machines cut cycle times in half at ARCH Medical Solutions – Newtown. But its leadership gives equal credit to a surprising factor: the OEM’s service department.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)