Share

GF Machine opened its North American Medical Center of Competence in Lincolnshire, Illinois on April 19 with a wide variety of machines on display. Between a versatile automation cell, intuitive EDM features and powerful lasers for both marking and micromachining, the technology on offer could spark shifts in medical manufacturing and beyond.

The automated cell at the heart of GF’s Medical Center of Competence includes a Form P 350 die-sinker EDM, a Mikron Mill S 400 U, inspection equipment, storage racks and a robot that manages it all.

The Automated Heart

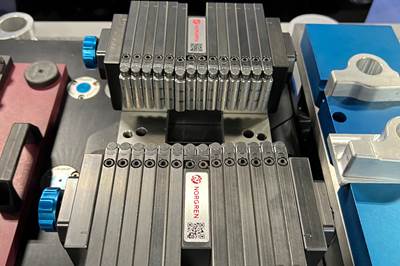

At the heart of GF’s Medical Center of Competence is an automated cell bringing together several of the company’s machine lines. Both low-volume, high-mix and high-volume, low-mix applications are possible on this demonstration cell, which includes a Mikron Mill S 400 U milling machine, a Form P 350 die-sinker EDM, 3R workholding devices and cell management software, a FANUC robot and a CMM. The S 400 U also has a grinding option and a wet electrode cutting option, while all machines benefit from 3R’s one-minute setup times and repeatability within several microns.

GF positions itself as being able to make previously impossible parts, using this cell and the rest of the machines within the Center of Competence to demonstrate new design possibilities to shop owners and product design teams.

Killing the Right Sparks

Of note was GF’s wire EDM technology. This includes both the Cut F 600, a mid-range offering making its North American debut at the unveiling, and the Uniqua control technology on both this machine and a higher-end Cut P machine.

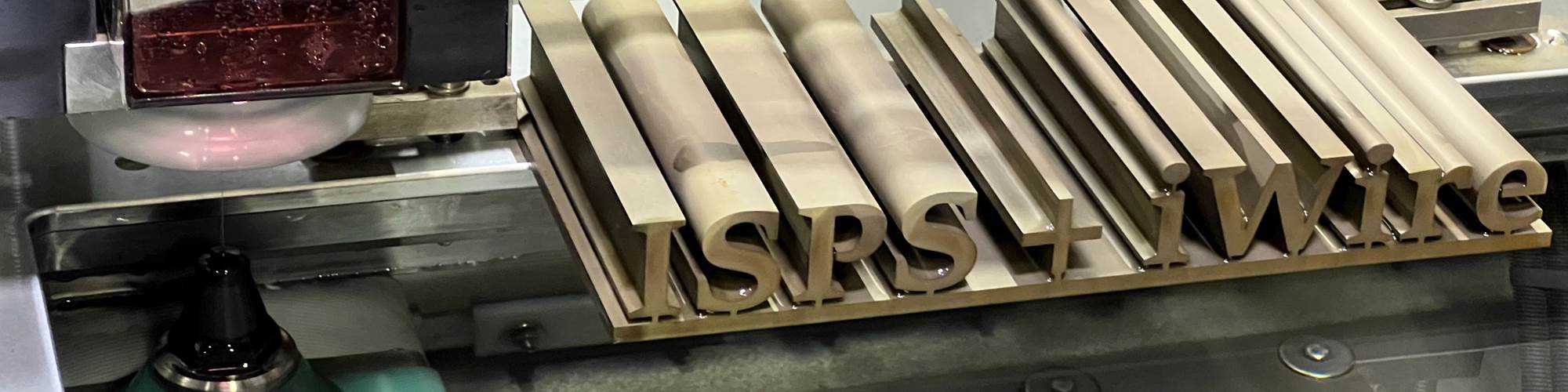

Both the new Cut F and higher-end Cut P EDMs include ISPS and iWire functionality in their controls. These features adjust sparks and wire feed rate to optimize cutting time and wire consumption rates.

The Cut F features increased accuracy compared to the budget Cut E machines, with more durable ballscrews, a liquid-cooled Y-axis, and an X-axis repositioned to benefit from this cooling. Visitors to the unveiling also saw a demonstration of GF’s iWire technology, which senses height differences between sections of parts and automatically compensates, reducing wire consumption. Company representatives say this feature saves an average of 27% of wire — but the demo part on the Cut P boasted 60% savings. This technology works in conjunction with GF’s ISPS (Intelligent Spark Protection System) technology, which uses a sensor close to the cut zone to analyze Z-axis sparks along the wire.

As with the height differences iWire observes, the control uses this information to adjust cut parameters, reduce wire breakage and maximize operation speed. Erik Poulsen, GF’s medical marketing manager, says the technologies in the Uniqua control provide an unmatched level of fine control — even predicting the strength of individual sparks and killing single, overpowered sparks to maintain a smooth process.

GF’s also showcased an important update to its die-sinker EDM technology: iGap. This software ensures sparks only form on the front of the electrode, not the sides. By controlling the location of these sparks (and concentrating the machine’s power), electrode wear decreases and average cycle times are 30% faster.

Laser Focus

The company has also been quietly developing powerful laser technology to perform not just texturing operations, but full-on micromachining. Visitors to the Medical Center of Competence opening event glimpsed both applications.

GF’s laser texturing software enables users to scan a desired texture and replicate it with a laser texturing machine, such as the Laser P 400 U on display in the Medical Center of Competence.

Texturing is more than a simple finishing operation for medical applications, with Poulsen describing laser-created textures that assist in osseo-integration and friction reduction, as well as textures that are hydrophobic, hydrophilic or anti-bacterial. Users can create these textures with relative ease, as GF’s laser machines are accurate to within tens of microns — enough to eliminate the need for masking — and texture programming is streamlined through an ability to scan textures into the control system for replication.

While GF demonstrated its laser machines’ ability to perform laser texturing at the Medical Center of Confidence, it showcased laser micromachining at its nearby Microlution facility. The company pointed to three machine types for different applications: the MLTC for tube cutting, general purpose ML machines and MLDS machines that pair a laser with metrology or boring stations for a high-end multitasking solution.

These machines can use nanosecond and femtosecond lasers, with nanosecond pulses creating a heat-affected zone that adds variability and femtosecond pulses achieving low surface variability without a heat-affected zone. Control over the lasers is now so fine that the MLTC can create features that aren’t through-features, and both the MLTC and the ML5 can perform OD turning with lasers. Spot sizes average 20 microns, with one demo part pushing the MLTC to an 11-micron spot size.

The ML5 is climate-controlled, five-axis laser micromachining system. The company’s engineers say the laser uses prisms to strengthen the beam, ending up with hundreds of Megawatts of power for the tiny fractions of a second in which the laser is pulsing. Parts can have negative, positive or zero tapers, and parts-cleaning is all but eliminated.

GF Microlution is making strides in laser micromachining. The company says it cuts about 80% of its test parts from stock using lasers, and can also perform OD turning and create non-through features at accuracies within several microns.

GF mostly relied on demonstrating test parts on the Microlution floor, as many applications in the medical field and beyond are under strict NDAs. These test parts showcased the extremes these machines could meet, with the 11-micron part mentioned above being a stainless-steel pipe 0.012 inch in diameter with a 0.009-inch hole and tiny, non-through-part features. Other sample parts made with GF Microlution’s laser lineup included representatives of aerospace and electrical work that the company made available for inspection under microscopes.

Erik Poulsen is convinced that micro lasers will be increasingly vital to medical manufacturing. EDM and conventional machining can both currently create parts on a much larger scale, much faster for a fraction of the cost — but the precision and detail laser micromachining can offer (not to mention its current usefulness in texturing) enable product designers to explore new ideas and target new standards in the ever-growing medical market and beyond.

Related Content

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreShould Blisk Machining be in Your Growth Plan?

Blisk machining offers a great business opportunity but requires technical expertise in machining difficult materials with multi-axis machines. The right partner can help you get started.

Read MoreFive-Axis Machines Speed NASCAR Engine Production

Moving from an aging set of five-axis mills to more advanced machines enabled Hendrick Motorsports to dramatically improve its engine production.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRead Next

GF Machining Solutions EDM Features Enhanced Control

The Cut F 600’s iWire function automatically identifies and adapts wire speed to changing erosion height conditions during the wire EDM process, eliminating wire breakage while reducing overall wire consumption.

Read MoreWhen Laser Cutting Precision Begins with the Quote

A harmonious marriage of CNC machining and sheet-metal fabricating equipment depends on identifying the right process and the right price for every part.

Read MoreAutomation and Process Simplification Define Eastec 2023

Manufacturing technology at this year’s Eastec met the market with tools to streamline operations and assist machinists in achieving greater productivity.

Read More

.jpg;maxWidth=300;quality=90)