Share

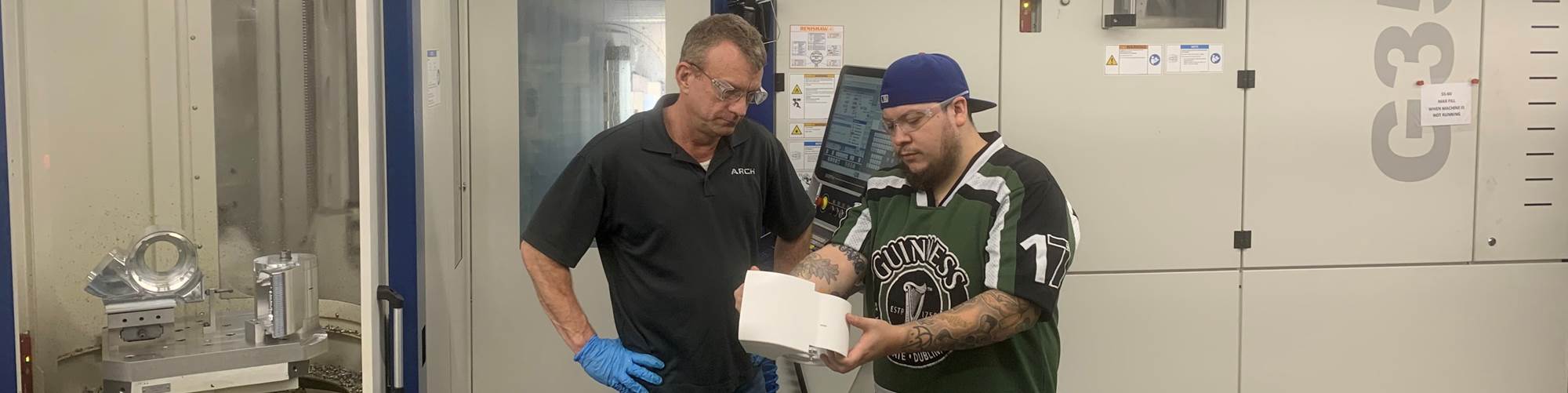

The G550 was ARCH – Newtown’s first Grob machine, and first five-axis machine. It combined work previously requiring two turning operations and one milling operation, completing the job in half the time of the original process. The machine’s expanded capacity from its pallet system has also enabled the facility to use the G550 for other large parts, where it often cuts cycle times by as much as 50%. Images courtesy of ARCH Medical Solutions – Newtown.

Medical parts take high-precision to extreme levels — in ARCH Medical Solutions’ case, oftentimes to tolerances as strict as a few ten-thousandths of an inch. Meeting this level of quality requires meticulous machines. Meeting it promptly requires an equally meticulous process. In 2020, ARCH’s Newtown, Connecticut, facility bought a five-axis Grob machine to consolidate operations for a medical robotics part from several machines to one. When this proved successful, the facility invested further into Grob with a turnkey machine. This second machine lowered cycle times for several applications by 50% — but to the staff, the technology in the turnkey machine is equaled in importance by the facility’s experience with Grob’s technicians and process engineers.

Making Medical Machinery

ARCH Medical Solutions operates over 20 manufacturing facilities across the U.S., with the majority working on orthopedic implants. The Newtown facility is one of about 30% that instead focus on medical capital equipment — centrifuges, clinical analyzers and robotic surgical devices, for example.

The Newtown facility began to investigate Grob machines in 2019 to produce a surgical robot component. Work on a centrifuge rotor required two turning operations and one milling operation, the latter on one of two old four-axis horizontal machines. When management encountered the five-axis horizontal Grob G550, they found the size of the table more than fit the 630-mm by 630-mm pallets for the rotors. Equally important, the pallet system and axis layout struck them as useful for consolidating operations and facilitating lightly staffed third-shift production.

After visiting other shops and hearing positive feedback about the G550, the facility moved forward with the machine in early 2020. Combining setups and operations decreased work-in-process and throughput time by half, while the combined operations freed up the older machines and made the job much easier to schedule. The improvements were drastic enough that the facility also found additional capacity on the G550 machine, which it can use for its other large parts.

“Helping us develop our talent is just as critical as having a good piece of equipment,” Young says.

Turnkey Service

In 2022, the shop returned to Grob to purchase a turnkey G350 that could specialize in the facility’s smaller parts. The same benefits from the G550’s pallet system and five-axis setup held true for this machine, even with a smaller work envelope and pallet size (this one 400 mm by 400 mm). ARCH presented Grob with two applications it wanted to complete on the machine, targeting a 50% improvement in cycle time.

When Grob delivered a presentation to ARCH proving that “they had a workable vision that they could attain,” as put by ARCH Medical Solutions – Newtown’s VP of Operations, Don Stankus, ARCH asked Grob to produce test versions of the parts the machine would need to run. After designing the fixturing and tooling the machine would need for optimal performance, Grob ran the parts at its facility and tested them with a CMM, rather than sending them to ARCH for initial inspection. Stankus says this was a pleasant surprise, as most turnkey providers the company had worked with in the past did not have ways to inspect parts on-site, and Grob’s ability to do so shortened the turnkey development process.

Grob’s thorough testing of the turnkey solution prior to sending it for installation at ARCH also cut a lot of difficult process development work for the shop. In the past, Stankus says, turnkey partners tended to step away from projects after making a viable part, not a viable process. This often left ARCH to redevelop the process, usually causing about as much work as if the company was designing a process from scratch. “Most of the time we seem to get to 80% of a complete part, then it becomes difficult and it takes a long time to finish it,” Stankus says.

“That last 20% takes 80% of the effort to get it across the finish line,” agrees Joe Young, president of ARCH Medical Solutions – Newtown. But Grob handled this last 20% on its own before handing it off to ARCH, surpassing the initial cycle time targets for the turnkey project in the process.

To install the machine, Grob sent a technician who would not only set it up, but spend three weeks training Brian O’Leary — the shop’s process engineer — in designing five-axis programs and using the Siemens Sinumerik 840D control, which was new to everyone at the facility. “Helping us develop our talent is just as critical as having a good piece of equipment,” Young says, and he credits the technician with helping O’Leary and the ARCH team upskill quickly enough that the facility could transfer its parts to the machine almost seamlessly.

Process Engineer Brian O’Leary (left) spent three weeks training with a Grob technician to learn how to use the Grob G350’s Sinumerik control. After O’Leary shared this training with his team, Lead Machinist Jonathan Urvina Palmer (right) has been able to prepare difficult operations with ease.

Usability and Usefulness

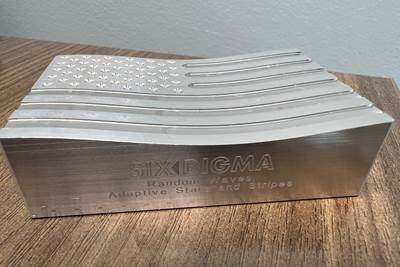

Training on the Siemens control swiftly spread across ARCH’s shop floor, and according to O’Leary, the control’s preloaded cycles for difficult machining maneuvers (such as swivel cycles) and its graphical interface have won over most of ARCH – Newtown’s operators. Several features have also caught management’s eye, with Stankus pointing to the control’s ability to track parts by their position in a lot or pallet as a great boost to traceability. He also notes that the shop has benefited from functionality that enables operators to to freely add subroutines to perform operations like engraving.

Performing this sort of experimentation in the medical manufacturing sector may seem reckless and foolhardy — but the benefits go beyond the Newtown facility to other machine shops under the ARCH brand. Namely, an ARCH facility in Sonora, California, also uses Grob machines to create components for medical robots, enabling both facilities to share their optimized part programs for greater cycle time gain. The Sonora team has also been able to provide stopgap training and support when required until Grob is able to send one of its technicians.

According to Stankus and Young, ARCH typically doesn’t need to wait long for that technician. The facility uses Grob’s web-based support service for most minor questions or repairs, with a technician arriving relatively promptly for more difficult repairs. What’s more, this technician is typically the same one who installed the G350, so he has a familiarity with ARCH’s equipment and a rapport with the staff.

“That’s just as valuable as the equipment, because if you can’t make the thing sing, then you aren’t going to make money on it,” says Young. “They do a great job of helping us to fully utilize the capability.”

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreRead Next

Investing in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read MoreThe Benefits of Horizontal Turning on a Mill-Turn Machine

A mill-turn machine that can rotate a large, bell-shaped workpiece in a horizontal orientation enabled this manufacturer to hit tight tolerance and cost targets. Minimizing non-value-added time and running lights out were also essential for success.

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read More