MC Machinery Systems Officially Opens New Headquarters

Last week, MC Machinery Systems Inc. officially opened its new, larger headquarters in Elk Grove Village. Cynthia Kushtush from sister publication Moldmaking Technology was there to cover it. Here is a small sampling of what she saw.

Share

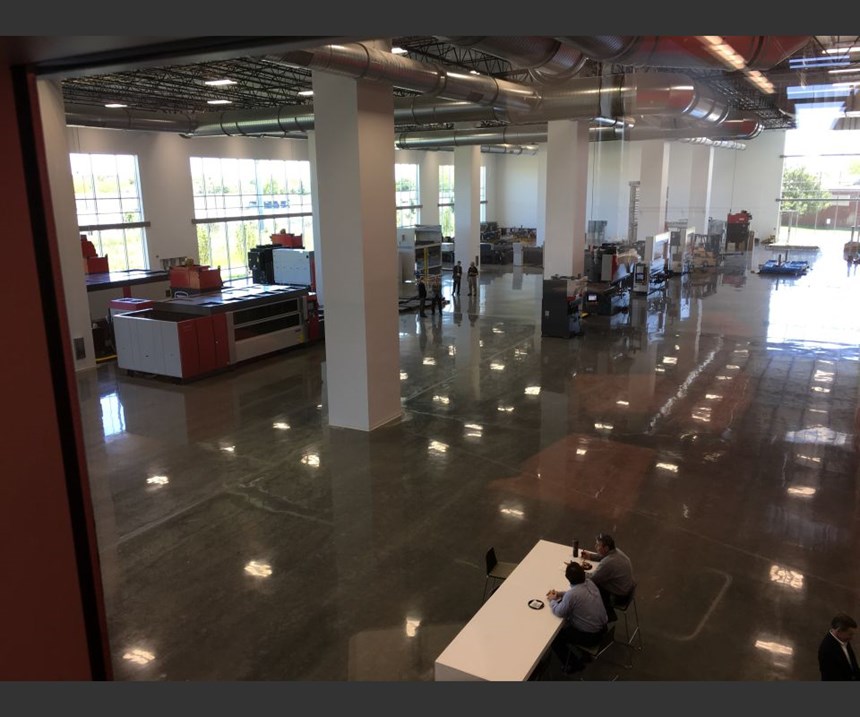

On June 30, 2016, MC Machinery Systems Inc., a subsidiary of Mitsubishi Corporation, announced its plans to build a new, larger facility in Elk Grove Village, Illinois. The announcement came with company representatives and partners from The Opus Group, Elk Grove Village and Heitman Architects overturning that first shovelful of dirt and, according to a few who were there, virtual reality headsets showing how the building would look when built. Well, last week they found out. MC Machinery Systems hosted an official ribbon-cutting ceremony with employees, partners and press (myself included) on hand.

"All of our competitors are located along Interstate 90 here," said Patrick Simon, marketing and corporate planning manager, during the opening ceremony. "You come out of O'Hare and this is the first building you see." He went on to explain that a gentleman from Ohio flew in to visit a competing EDM supplier, saw the MC Machinery signage on the building, and decided to stop in. "We did a demo for him, and I think we may have sold a machine."

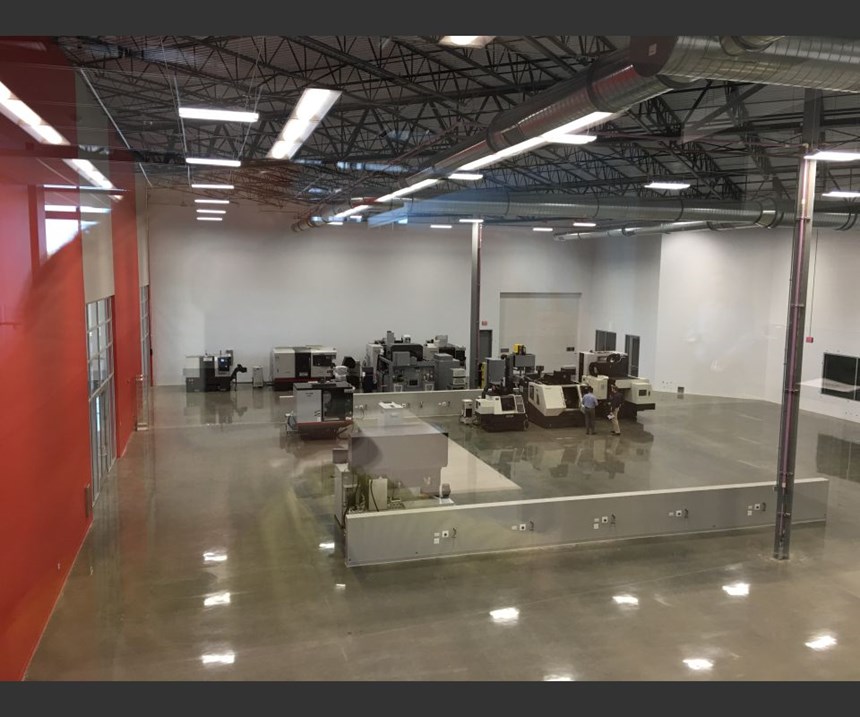

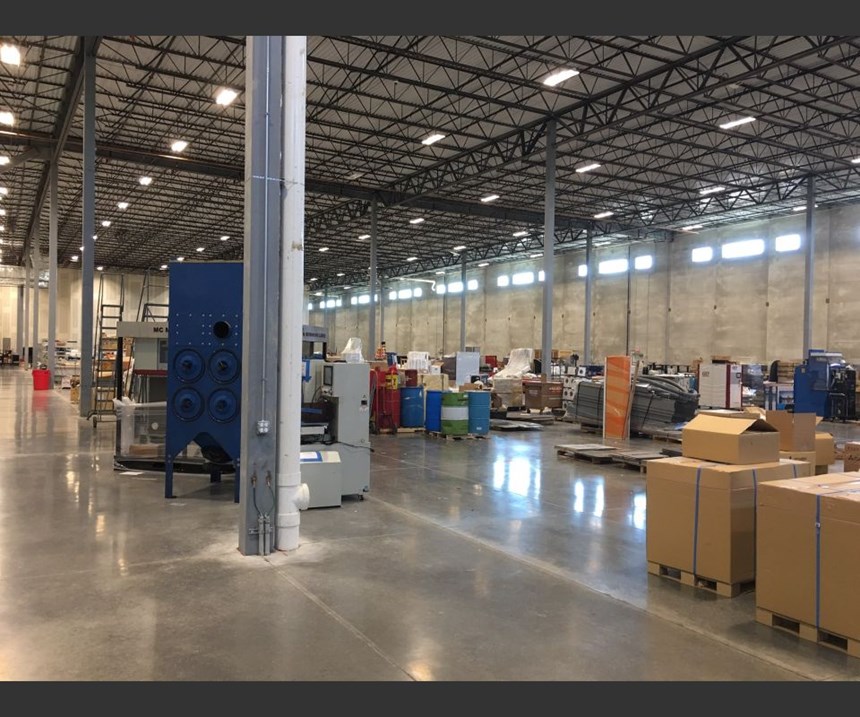

Above is a slideshow of highlights I put together after touring the new building. Mr. Simon said an open house event is in the planning stages for customers and others to visit, tour and see demonstrations of Mitsubishi EDM and laser, milling and turning, press brake and other machines. Take a look.

Related Content

-

Dielectric Oil Dramatically Reduces EDM Maintenance

Plagued by repeated small fires that interrupted its wire EDM throughput, this cutting tool manufacturer changed its dielectric oil and both eliminated fires and reduced its oil consumption.

-

Hybrid Control Makes Lights-Out EDM More Accessible

This CNC enables EDMs to switch between G-code and an integrated CAM system to adapt to changing conditions and make lights-out manufacturing more attainable.

-

GF Machining Solutions Celebrates 70 Years of EDM Technology

GF Machining Solutions is celebrating the 70th anniversary of its discovery of EDM Technology.