Share

Producing parts at high volumes often means that minor process improvements can dramatically impact the cost of production. Often, a single change in technology utilization can yield results that have a sizable impact on a part’s profitability. Likewise, slowdowns and bottlenecks in production can be costly.

At cutting tool manufacturer Ceratizit, the problem was unusual: Its wire EDMs kept catching on fire.

When Oil Causes Friction

Ceratizit is a cutting tool manufacturer that focuses on high-end tooling for the metalworking industry. Ceratizit USA, the United States branch of the company, is headquartered in Schaumberg, Illinois, where it produces both standard and custom tooling for shops working in the automotive and aerospace industries, among others.

The company’s tooling offerings include polycrystalline diamond (PCD) cutting tools. PCD’s extreme hardness and wear resistance make it an excellent choice for cutting tools, as it can outlast solid carbide tools by 10 times or more, according to the company. However, its desirable qualities also make it a challenge to cut into shape, which is one reason why the company relies on wire EDMs for producing PCD cutting tools.

Unfortunately, the wire EDM production line for PCD tooling, which includes five machines and is intended to run 24 hours a day was plagued by disruptions.

According to the company, the EDM department was a high consumer of cutting fluid, specifically the dielectric oil used for the wire EDM process. “Oil loss from evaporation and dragout — oil clinging to parts as they’re removed from the machine — dramatically impacted our oil consumption,” Facilities and Maintenance Manager Manfred Haemmerle says.

Additionally, the filters needed changing two to three times a year. “When you do a filter change, more product is also taken out of the machine and fresh product must be installed,” Haemmerle explains. “It’s the labor, too. Changing filters is not a half-hour job; it’s a half-day job.” Altogether, these drains on the oil supply forced the company to go through four to five drums of oil every year.

While these oil-consumption woes were concerning, the physical qualities of the dielectric oil caused an additional problem. The oil had a relatively low flash point — the temperature at which a material ignites — which led to repeated fires in the machines as they cut the PCD.

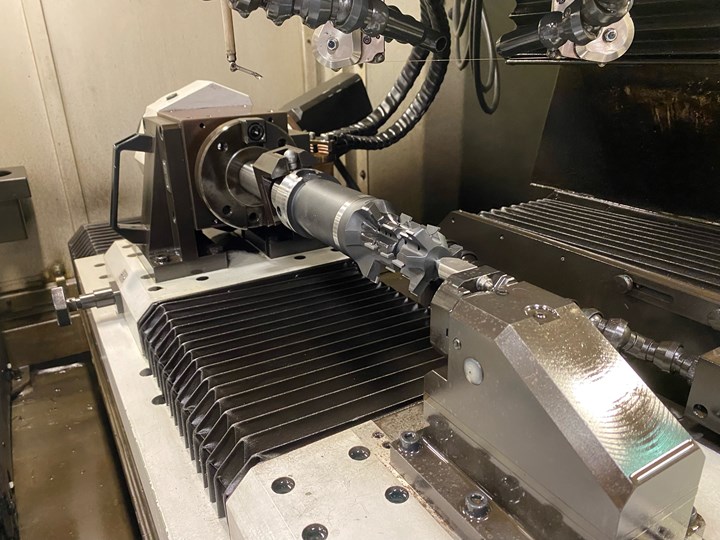

PCD cutting tools exhibit extreme hardness and wear resistance, enabling them to outlast solid carbide tools by 10 times or more. However, the company aimed to have its production line running 24 hours a day, and the EDMs cutting the tools into shape were experiencing downtime due to fires caused in part by the dielectric fluid’s low flash point. Photo Credit: Ceratizit

“We were experiencing at least two fires per machine every year,” says Haemmerle. “That is in addition to numerous flare-ups that quickly died out.” Each EDM is equipped with a fire-suppression system that floods the work area with carbon dioxide the moment it detects a fire. At no point were the workers in danger, nor were the machines at risk of being permanently damaged. But the fires (and even the small flare-ups) would still damage the machines.

The need to replace damaged machine components led to days of downtime every year. On top of that, the company needed to replace the CO2 cannister that doused the fire before an EDM could boot up. “We will not start a machine unless it is totally safe to do so,” Haemmerle says. Eventually, the company began keeping multiple cannisters of CO2 in stock to avoid last-minute replacements that would cause further downtime.

Essentially, the company was planning around the expectation that its EDM oil would occasionally flare up, and that was costing it in material losses, machine component replacements and machine downtime. Looking for a more manageable process, Ceratizit reached out to Blaser Swisslube for a solution.

Reducing Costs, Eliminating Fires

After consultation with Blaser and their local distributor DXP Enterprises, Ceratizit decided to try out a new dielectric oil, the Blasospark GT250. DXP Oil and Coolant Specialist Andy Anderson convinced the company to try the new fluid, which is a synthetic paraffin oil converted from natural gas, eliminating impurities that can contaminate products derived from crude oil.

Ceratizit eventually turned to its supplier, who suggested a new dielectric oil with a flashpoint twice as high as the old one. This has eliminated fires in the EDMs. Photo Credit: Ceratizit

The biggest draw of the new oil is its higher flash point, igniting at 230° F, roughly twice the temperature of the previous product’s flash point. Since adopting this oil, the company has yet to have a single fire in its wire EDM line, allowing it to scale back its stock of CO2 cannisters and eliminating costly downtime.

Additionally, the replacement oil is less prone to both evaporation and dragout, and the filters need changing only once every year. “With our previous product, we were going through four to five barrels every year,” Haemmerle says. “With the Blaser oil, it’s only one barrel a year.”

With one process change, the company has dramatically reduced maintenance time, oil consumption and machine replacement parts. Ceratizit is now running its wire EDM line much closer to its 24-hour goal, improving its production of PCD cutting tools.

It is not often that you fight fire with oil.

Related Content

New Look, New Feel, New Robots at System 3R

Are AMRs the next big trend in job shop automation? System 3R’s IMTS booth will emphasize both its specialty EDM tooling and its automation products, including an autonomous moving robot.

Read MoreGF Machining Solutions EDM Features Enhanced Control

The Cut F 600’s iWire function automatically identifies and adapts wire speed to changing erosion height conditions during the wire EDM process, eliminating wire breakage while reducing overall wire consumption.

Read MoreEDM Network Wire EDM Features Four-Axis Cutting

The EDMMax 434W fast-wire EDM includes four-axis cutting capability that enables it to cut 3D support structures or other shop-related parts.

Read MoreMWI Introduces Wire EDM Consumables Designed to Maximize Energy Efficiency

Blac Technology’s specialized composition is designed to provide uniform distribution and embedding of particles throughout the surface.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)