When Nilpeter embarked on a lean initiative 14 months ago, no one at the printing press manufacturer had any inkling that they had already taken an important first step. As it turned out, a previous equipment purchase, made for an entirely different reason, dovetailed perfectly with the company’s efforts to reduce waste and improve efficiency.

Since installation in mid 2010, the LT 300-MY turning center from Okuma America Corporation (Charlotte, North Carolina) has been performing exactly as expected. So have the accompanying Hydrobar Sprint S3 bar feeder and BlazeAir vacuum unloader, both from LNS America (Cincinnati, Ohio). As a result, Nilpeter has improved productivity on one group of its most critical parts by 90 percent, says Steve Sander, machining manager.

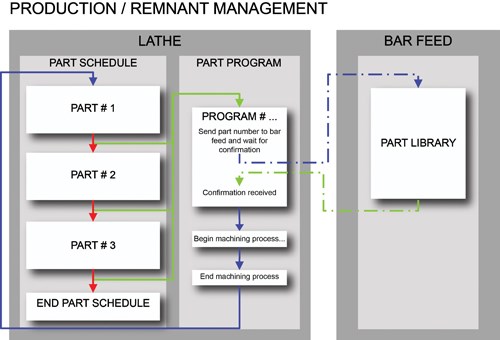

While each piece of equipment certainly played its own role, Mr. Sander attributes much of that gain to the system that ties all three together: e-Connect, an Ethernet-based communications system from LNS. By enabling the lathe, bar feeder and unloader to exchange critical data—and more importantly, to act intelligently on that data—this system significantly simplified changeovers and reduced material waste.

Little did Mr. Sander know that months down the road, those same advantages would play an important role in reaching a more expansive goal. That is, facilitating Nilpeter’s move away from producing parts in relatively high-volume batches and toward a just-in-time, on-demand strategy. “e-Connect wasn’t initially part of our lean plan, but it has definitely worked out to our advantage,” he says.

A Captive Shop

Nilpeter traces its roots to 1919, when it produced its first printing presses in Copenhagen, Denmark. In 2001, Nilpeter bought out another company and started operations at its 65,000-square-foot plant near Cincinnati, Ohio, marking its first foray into the U.S. market. The company manufactures five distinct lines of presses at that facility for label and packaging printers.

Each press includes approximately 300 unique components, depending on the model, and Nilpeter produces all but about 15 percent of these at its in-house machine shop, Mr. Sander says. While the company maintains four VMCs and an HMC fitted with a 20-pallet automation system, a large portion of its work consists of cylindrical parts processed on three Okuma turning centers. Among those machines, the LT 300-MY is the workhorse, Mr. Sander says, processing as many as 90 percent of all non-hollow, cylindrical production parts longer than 6 inches.

A Pressing Need

The volume of work processed on this lathe accounts for much of the reason why communication with its attendant bar feeder would have further-ranging consequences than anyone anticipated. At the time of purchase, however, the company had a narrower goal in mind: to improve productivity on a family of impression rollers, which are critical components of each press. Nilpeter manufactures eight of these components, which vary slightly in diameter from 2.2618 to 2.2621 inches. That might not seem like much of a difference, but consider that evenly applying images to the material being printed requires these rollers to meet final diameter tolerances of ±0.00005 inch.

The previous manufacturing process for these rollers was “tedious,” to say the least, Mr. Sander says. After cutting the 1215 stainless steel stock to length, blanking it and facing it on a manual lathe, the part would be sent out for gundrilling. Then, it would return to Nilpeter for turning on a CNC lathe before being sent out again for pre-grinding and chroming. Finally, it would return to the facility for finish grinding. Nilpeter devoted a total of 4.5 operator hours per impression roller, in addition to the time each part spent outside the facility.

A Critical Link

Nilpeter selected the LT 300-MY on a recommendation from Dave Marsh, sales and application specialist at Gosiger, the company’s Dayton, Ohio-based Okuma dealer. With twin turrets and seven axes, the machine enables precise turning of both ends of the part as well as milling and drilling operations. This has eliminated the need to send the rollers out for gundrilling. Meanwhile, the LNS Sprint S3 automatic bar feeder features a hydrostatic, self-opening bearing block design. This provides the smooth, continuous loading and the bar support needed for the lathe to operate at its maximum rpm and to reduce vibration, a critical factor in maintaining the tight tolerances the rollers require, Mr. Sander says.

For its part, e-Connect made change-overs within the impression roller family quick and easy, he explains. Rather than manually intervening at the lathe’s THINC OSP control to switch among the different rollers, operator Bob Silcott had only to load the day’s production schedule and ensure the feeder was adequately stocked with 2.75-inch barstock. When production shifted to a different-diameter roller, the bar feeder would automatically detect the program change via the Ethernet link and load the corresponding setup data for the new part, including cut length, top position and so forth. In this way, the system contributed to reducing production time from 4.5 operator hours to less than half an hour per part, Mr. Sander says.

Connecting With Lean Ideas

More importantly, however, e-Connect’s capability for seamless change-overs turned out to be a useful means toward another end: consolidating the product mix. That consolidation was part of a broader effort to reduce waste and streamline production that the company embarked on approximately a year ago. Andy Colletta, company president, was inspired to rethink Nilpeter’s production strategy after visiting a customer that was deeply involved in its own lean initiative. “Seeing that operation really set the light bulb off in his head,” Mr. Sander recalls.

It wasn’t long before Nilpeter hired an outside consultant and began an extensive review of all aspects of its business that continues to this day. On the manufacturing side, the chief goal was to produce parts as-needed according to demand from the assembly department, as opposed to producing parts in bulk according to quarterly forecasts. This would ensure better use of capacity, reduce stored inventory of finished parts and avoid problems associated with inaccurate forecasts, Mr. Sander explains.

One of the first steps toward implementing this new just-in-time strategy was working to reduce setup time. This would be particularly important for the LT 300-MY and bar feeder, considering the volume of work that moves across that machine. Practices such as pre-staging needed materials and having two operators work together helped reduce the time required for a complete change-over from 2 hours to less than half an hour. However, management soon realized that lengthy individual setups weren’t the only thing holding back its efforts.

Consolidating the Mix

Historically, Nilpeter has maintained stores of 15 different diameters of barstock, but that started to make less sense as the company dived deeper into its lean initiative. “The first thing we did was reduce setup time, but once we’d done that, the question became ‘Why are we setting up so often?’” Mr. Sander recalls. “Why do we need to have barstock in every eighth-inch increment?”

After closely examining its mix of nearly 100 different turned parts, Nilpeter determined that the vast majority could be produced from five different barstock diameters: 0.75 inch, 1 inch, 1.5 inches, 2 inches and 2.75 inches. Consolidating products into five families based on these diameters would not only reduce the number of setups required, but also simplify the purchasing of raw material by reducing the need to carry large inventories of different-diameter barstock.

Just as it did with the eight models of impression roller, e-Connect has eased change-overs within each of these five part families. However, now that it’s applied on a broader scale, the system’s benefits go even further, namely by helping the company make the most of its raw material. Additionally, the system is sophisticated enough to work with Nilpeter’s job-scheduling priorities, Mr. Sander says.

During production, the bar feeder continuously tracks material usage and informs the turning machine how much stock is available. If remaining stock is insufficient, the system searches the production schedule for another part that could be produced with the remaining barstock, opting to switch to the highest-priority parts first. In the event that it identifies another job, it loads the corresponding setup data for automatic, seamless change-over. Otherwise, the system either instructs the feeder to eject the remnant and load the next bar or alerts the operator that a change in barstock diameter is required to proceed.

“When we originally bought this equipment, we liked the fact that we could basically load the bar and let it run,” Mr. Sander says. “The beauty is that it’s just as easy to make ones and twos of 20 different part numbers as it is to make 20 of one part number. We just schedule the programs at the lathe control, tell it how many parts we want, and it’ll use the optimal amount of material to churn out as many as possible before we have to change to another bar diameter.”

Looking Ahead

The company is currently considering replacing the bar feeder on another lathe, an Okuma Captain-L370, with new LNS model equipped with the Ethernet system. That would extend the benefits already realized on the LT 300-MY to the smaller parts processed on the Captain-L370, Mr. Sander says. The company also has yet to take advantage of some e-Connect functionality, including the ability to analyze and adjust the production schedule from a remote location and receive automatic email alerts for faults or errors.

Regardless of whether Nilpeter follows through with these tentative plans, the system has already played a modest, yet important, role in helping to reduce waste, labor costs, and both raw material and finished part inventory. As the company continually strives to improve efficiency, it will no doubt look to streamlined data communication among its equipment as one possible way to facilitate additional lean connections.

.jpg;maxWidth=300;quality=90)