Share

Okuma held its 2023 Technology Showcase event March 7-8 at its newly renovated facility in Charlotte, North Carolina, as well as at its Partners in THINC facility.

Thoughts of factory automation usually bring to mind robot (or these days, cobot) arms tending machine tools. But as Tim Thiessen, VP of sales and marketing at Okuma, points out, automation is a much broader concept that includes everything from bar feeders and pallet systems to gantry loaders and software. Shops have different needs based on the size and volumes of parts they produce. A high-volume precision turning facility can automate with bar feeders and parts catchers, while a job shop producing low volumes of complex parts can benefit from a pallet changer.

Several of the machines demonstrated at the event included automation, including this MB-80V large-capacity bridge mill, which featured an automatic pallet changer with two pallets.

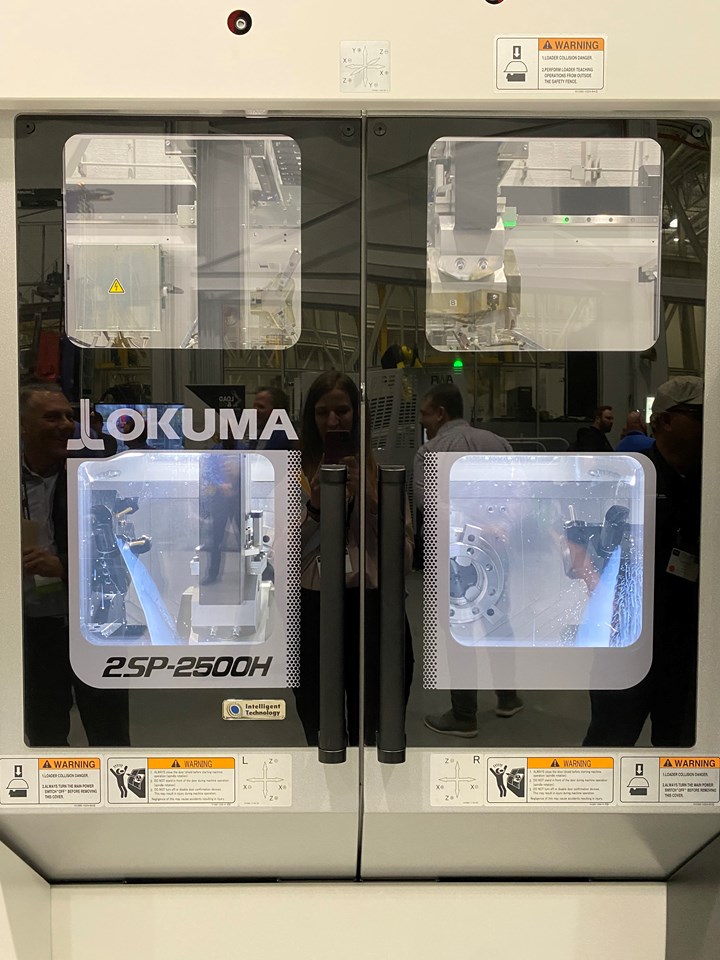

This mindset was on full display at Okuma’s 2023 Technology Showcase, held March 7-8 in Charlotte, North Carolina. Many of the machines featured at its newly renovated headquarters and its Partners in THINC facility had some form of automation. Highlights included the MB-80V, a large-capacity bridge mill in a compact footprint, which was paired with a two-station automatic pallet changer (APC), as well as the 2SP-2500H, a horizontal lathe with two front-facing chucker spindles. The machine’s orientation is designed to work with one or two gantry loaders, reducing cycle times and loading/unloading times.

The 2SP-2500H is a horizontal lathe has with two front-facing chucker spindles that are designed to work with gantry loaders, as shown at the event.

Okuma works with a number of companies that specialize in automation through its Partners in THINC program. This is a collaborative network of more than 45 companies that serve the metal-cutting and manufacturing industry that works together to solve problems and explore new ideas to increase productivity for real-world manufacturers, including automation. Members include software providers, integrators and OEMS that make everything from robotic arms to bar feeders to tooling, workholding and inspection equipment.

Related Content

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

-

Facilitating Lean Manufacturing Through Modularity

Knowing how to subdivide machines and jobs has enabled Danobat to create a lean manufacturing process that improves its lead times by up to 25%.

-

Custom Motorcycle Parts Made Here: Video Tour of a Family-Owned CNC Machine Shop

Lee Wimmer invited us to tour his second-generation family-owned machine shop in Perkasie, PA. This video explores the production processes behind precision-machined parts for both Wimmer Custom Cycle and LS Wimmer Machine Co., and shows how ingenuity and determination are still at the heart of American manufacturing. Today, both companies are now managed by Wimmer’s three sons.