Articles

A Hair’s Width—Micro Grooving on Swiss Machines

An article about cutting grooves to the width of a human hair came within a hair’s width of appearing in our April issue. It got yanked at the last minute, so it’s offered here as it awaits publication in an upcoming issue.

Read MoreCenter Rock and Setups

Just because a machine can run a part in one setup, that doesn’t mean it should.

Read MoreSwiss-Type Sculpting Serves Complex Parts Complete

With capability for continuous cutting using a swiveling B axis tool post, this Swiss-type lathe enables users to machine complex, sculpted geometry without moving parts to another machine.

WatchWhy Shops Are Considering Swiss-Types

These days, more traditional job shops are installing—or at least eyeing—Swiss-types. Here are some reasons why.

Read MoreMicro Grooving on Swiss Machines

In any turning application, grooving can be a critical, even challenging, operation.

Read MoreNew Idea in Shopfloor Gaging

In many manufacturing facilities, production measurement and programmable measurement are two separate things. Read how one company’s new product represents a new idea in gaging.

Read MoreDesign the Parts Around the Process

To guarantee that components for a new helicopter could be readily produced, the company looked at the capabilities of available machine tools in the market first, and then finalized the design of the components accordingly. It created a Precision Components Technology Center to embody this concept as a process for R&D prototype work. What has emerged is a flexible production model that can be duplicated at its other facilities.

Read MoreA New Milling 101: What Customers Demand

Part 5. For W Machine Works in San Fernando, a custom variation of the WIDIA-Hanita VariMILL II solid end mill proved especially effective in roughing and semi-finishing applications in stainless steels, high-temp alloys, nickel- and carbon-based alloys, and titanium.

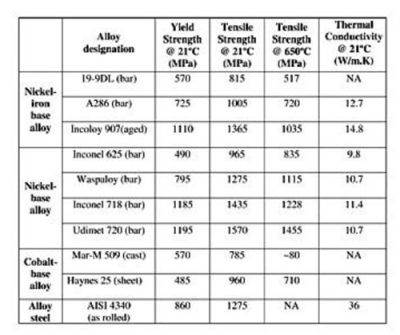

Read MoreA New Milling 101: Selecting Tool Materials and Coatings

Part 4. The emergence of new workpiece materials is driving the development of new cutting tool materials and tool coatings. These, in turn, are driving the development of new milling processes and techniques.

Read MoreA New Milling 101: What Milling Is, Then and Now (Plus a Glossary of Milling Terms)

Part 1: Greater understanding of milling tools, what they can accomplish, and the optimum circumstances in which to employ them, is always valuable. The continuing development in milling tools in the face of changing customer requirements, advanced workpiece materials, and the constant need to improve productivity while reducing costs make this even more important today.

Read MoreA New Milling 101: Cutter Design and Application Considerations

Part 2: Cutting tool geometry governs almost all design and application considerations related to various milling choices.

Read MoreMachine Tool Sales Still Strong – Up 131% in January

According to USMTC, machine tool sales in January were 130.5% (units) and 178.8% (real dollars) more than in January 2010.

Read More