Published

Why Shops Are Considering Swiss-Types

These days, more traditional job shops are installing—or at least eyeing—Swiss-types. Here are some reasons why.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

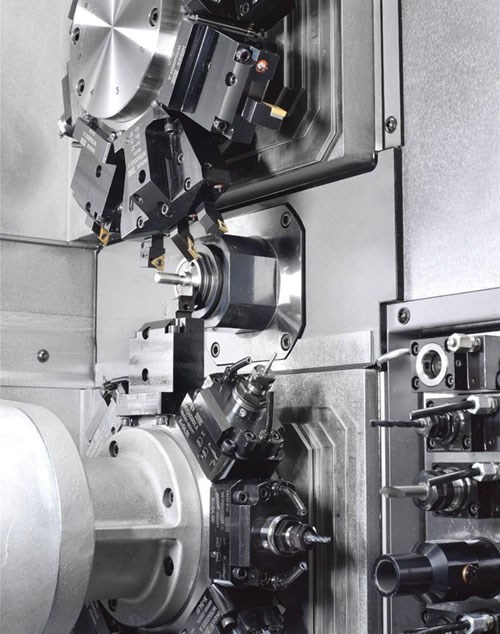

Some shops like that a Swiss-type’s guide bushing can be removed

so they can perform conventional turning.

so they can perform conventional turning.

These days, more traditional job shops are installing—or at least eyeing—Swiss-type lathes. That’s largely because Swiss-types can rapidly perform both turning and milling operations, enabling shops to machine intricate parts complete rather than running them across multiple machines. Recognizing this, manufacturers of Swiss-types have integrated design elements into their sliding-headstock machines to boost their effectiveness in environments where the work is diverse and the batches are small. Learn more.

Related Content

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.