Articles

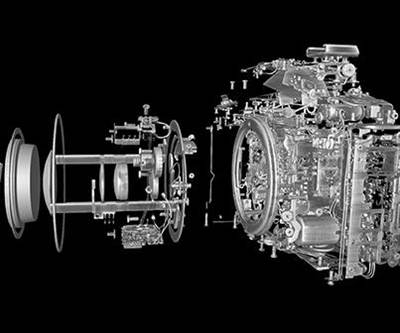

CT Scanning Moves from Lab to Production Line

In addition to raw computing power, new microfocus source designs and intuitive software make this technology ready for the production line.

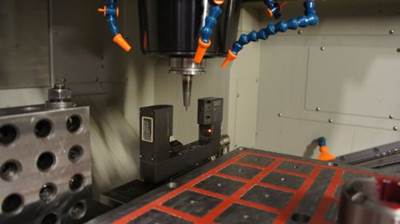

WatchOn-Machine Verification Keeps Process Chain Intact

Measuring on machining centers is no substitute for this mold manufacturer's CMM. Rather, the goal of on-machine probing is to minimize downtime at individual workstations and to maximize overall throughput.

Read MoreRedefining the Rustbelt

From Akron, Ohio, to Albany, New York, former manufacturing towns are charting a course toward a brighter future as a hub of innovative thinking leading to the production of smarter products, not just cheap ones.

Read MoreVirtual Training Helps High Schools Teach CNC Skills

Machine Training Solutions is paving the way to bring virtual CNC training and mentoring to high school honors students.

Read MoreIngenuity Meets Automation. Lunch Meets Learn.

Sponsored Content – IMTS 2016 Technology eNewsletter

Read MoreMeet the Humans Behind Makino Adaptive Automation

Sponsored Content - IMTS 2016 Technology eNewsletter

Read MoreCaterpillar’s Deployment Strategy for Additive Manufacturing

A dedicated AM facility is helping the company discover the technology’s potential for design as well as production.

Read MoreMore Shop Dogs

A few weeks ago, I introduced Bandit, a border collie who runs a continuous mood improvement program at a CNC Swiss shop in North Carolina. More readers responded with notes about their shop dogs.

Read MoreTraining the Manufacturers of Tomorrow

With help from Edgecam, Northern Maine Community College trains the next generation of skilled manufacturers.

Read MorePut Employees’ Skills on Display

A shop interested in cross training publicly scores its employees according to how much time they spend with different types of equipment.

Read MoreDoosan Technical Center Offers Collaborative Environment

Customers, industry partners and U.S. distributors gathered recently to celebrate the opening of Doosan Machine Tools’ new site for demonstrations and collaborations.

Read MoreBroken-Up Programs Limit Broken Tools

Posting tool paths for different operations to the machine individually rather than as a single, combined part program helps this heavily lights-out operation quickly address the causes of tool wear and breakage.

Read More