Articles

Fear Kills More CNC Machining Businesses Than Recessions Ever Will

Look at hard data to make fact-based decisions.

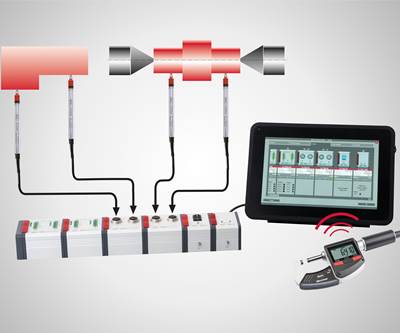

Read MoreTool Setting Fixture Boosts Process Security for High-Volume Shop

Along with switching to a different milling tool to improve surface finishes on aluminum parts, Alupress also employed Mapal's Uniset-P setting fixture to make the process reliable and efficient.

Read MoreDrilling and Chamfering Tool Solves Machine Shop's Vexing Problem

An oil & gas part with a lot of holes required that Utex use two different tools to ensure burr-free inner and outer diameters. With Heule’s Vex-S tool, the shop realized time savings per cycle of an entire minute by performing drilling and chamfering in a single step.

Read More3 Major Trends in Manufacturing (And They All Begin with “A”)

Peter Zelinski sees three long-term trends that continue to reshape manufacturing.

Read MoreWhat Makes a Top Shop Profitable?

The data from Gardner Intelligence's Top Shops survey can show us how technology and management tools relate to earnings and profit in machine shops. Register for this webinar to learn about some of the specific findings from the survey.

Read More10 Steps to a More Organized Work Area

Workplace organization can be overwhelming. Break it into smaller steps to make it more manageable.

Read More5 Mistakes We Find in Most CNC Machine Programs

While the mistakes listed here will not sound an alarm or cause a program to fail, they will cause confusion, wasted time and scrap parts.

Read MoreTemperature-Activated Adhesive Overcomes Limits of Magnetic and Vacuum Workholding

This new chemistry-based solution for five-sided machining allows for a diversity of metals and other workpiece materials to be used along with aggressive cutting forces.

Read MoreCan This Metal 3D Printing System Make Production Additive Manufacturing Common in Machine Shops?

A new metal AM system for batches of end-use parts was designed to permit productivity and machine pricing comparable to a CNC machine tool.

Read MoreReshoring News: November 2019

Program to provide $100 million to develop apprenticeship programs, legislation introduced to help close trade deficit, and Reshoring Initiative president has been appointed to the Department of Commerce Investment Advisory Council.

Read More5 Benefits of Sourcing CNC Machining Work Online

Machine learning saves time, makes pricing fairer, inspires improvement initiatives, and even insulates manufacturing businesses against economic shocks.

Read More