Keeping It in the Family

This small job shop utilizes CAD/CAM software to increase efficiency of older machines, improving part production and creating new business opportunities in the process.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

KPI Machining is a five-man manufacturing operation that produces a variety of components, fixtures and tooling for several different industries. It didn’t start out that way, however.

Barry Carpenter started the company out of his garage in Sheridan, Illinois, in the late 1970s with a single manual mill and a manual lathe. He found a niche specializing in gearbox production. The company soon added CNC machines and staff and moved to a larger facility. At its peak, the company employed eight. However, 2008 was devastating. Scott Carpenter, Barry’s son, recalls that the recession that year was particularly hard on KPI’s largest customer, and therefore on KPI. The shop had relied heavily on this customer’s business, and that strategy seemed to have backfired. “My father, like many small business owners, had one customer that made up 80 percent of his work,” the younger Mr. Carpenter says. “He had to close his doors because he didn’t diversify.” The elder Mr. Carpenter retired in 2008 and began putting KPI’s equipment up for sale. Seemingly, that was the end of the company.

Fortunately, the equipment didn’t sell quickly. Scott Carpenter and a friend, Eric Pine, were working together at a shop in Aurora, Illinois. Both were interested in what they saw as an opportunity to lead a small shop and build it into something larger. In 2011, Scott returned to KPI to help his father prep a machine that had recently sold. He informed his father during this visit that he was interested in buying what remained of the company. “I asked my parents not to sell any more of the equipment,” he says. But Mr. Carpenter’s parents were skeptical. “They weren’t going to just hand over the keys without a business plan,” he says. “It took six months of negotiating, but at last we came up with an agreement and I took over the business.”

Thus, KPI Machining officially re-opened its doors in 2012, initially with a staff of just two—Mr. Carpenter and Mr. Pine—and equipment from the original shop that included an older CNC machining center and a CNC lathe. They also added a newer (but still used) 1997 Haas VMC. The long-term goal, according to Mr. Pine, was to establish a diverse customer base and purchase multi-axis machinery to expand the company’s capabilities.

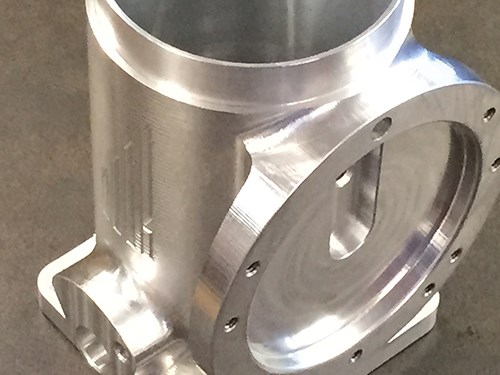

There was work from the very beginning. The shop immediately received orders for components in the oil and gas industry. The shop went on to produce other components as well, including pulleys, hubs, brackets, bolts and aircraft throttles. “The business actually took off fast,” Mr. Pine says. The challenge was how to take the shop’s existing machines, which are not fast relative to modern equipment, and apply them so they kept up with the business the shop was seeing.

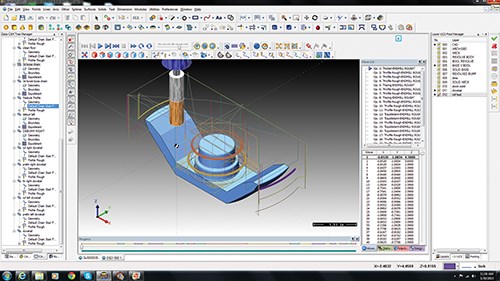

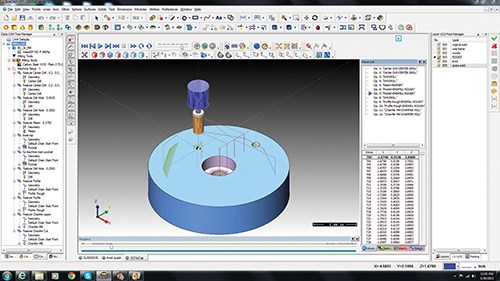

Both men say one feature that has proven particularly valuable in meeting this challenge is the high-speed adaptive roughing option in the shop’s CAM software, BobCAD-CAM. This option improves cutting efficiency by minimizing the stop-and-go action typical of traditional offset tool paths. In tool paths created with this feature, the tool remains engaged with the material throughout the cut. Because this produces a more steady load on the tool, free of stops and starts, KPI says it has been able to use this CAM feature to cut deeper, cut more productively and even utilize more of the length of the cutting tool itself in milling.

The high-speed option has saved even more than just time on several KPI projects, Mr. Pine says. With a conventional tool path, “you take a left, take a right,” but the adaptive tool paths, by contrast, are comprised of overlapping circular motions that follow the part geometry to keep the tool in the material. As a result, Mr. Pine says this feature produced no gouges or chirping in the corners of parts. “It not only saves the company a lot of cycle time, but it also saves a lot on tool wear,” he adds.

The constant engagement even applies in three dimensions. For example, another CAM feature that has benefitted KPI’s operation is contour ramping, which can be used for helical milling, slot machining, creating O-ring grooves, part profile roughing and hole milling. In all of these cases, instead of milling at a single Z level, the operator chooses either a depth per pass or an angle of cut. The resulting program then mills continuously down into the part instead of milling down in steps.

And in a way, CAD/CAM features enable the shop managers to stay engaged as well. Mr. Pine says that design changes to components or part families are no longer as time-consuming as they were for him in the past, thanks to the software’s ability to associate the part model to a CAM “tree” of the programmer’s choices. This enables features of the part to be changed without the program having to be rewritten.

If the design of the part does change, says Mr. Pine, he simply re-draws it, re-selects the changed model and re-computes the tool path by allowing the software to associate the new model to the existing CAM tree. This feature has been particularly helpful for designing part families. By associating a new part in a family to an existing CAM tree, the tool path can be programmed within minutes, he says.

These and other software features and functions have produced a variety of benefits for KPI. The leaders of this still-small, now five-employee shop were hesitant to buy up to the new capabilities at first, but they soon realized that pushing forward was part of the reason they wanted to run this shop in the first place. Fortunately, the software investment has paid off for the shop in that it has enabled KPI to realize a great deal of success with its existing hardware. With the profits of this success, investment in new multi-axis machinery will be next.

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)