“Intelligent” Chuck Regulates Clamping Force

Hainbuch is working to develop an “intelligent” chuck that monitors actual clamping forces on the workpiece and triggers necessary corrections automatically.

Share

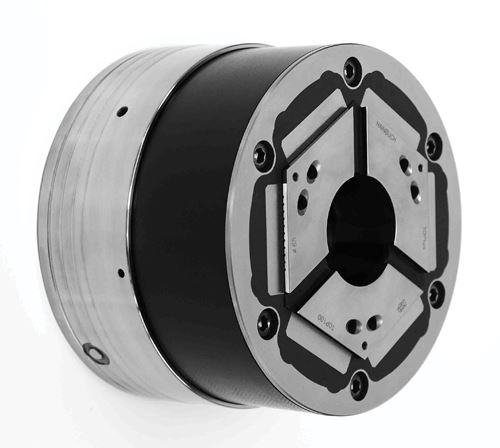

Developments in CNC, robotics and automation systems indicate an increasing trend in manufacturing technology—that is, an attempt to remove as much operator involvement as possible from the machining process. However, one product currently in the testing stages is evidence that this trend isn’t limited to only these obvious examples. At its headquarters in Marbach, Germany, workholding manufacturer Hainbuch is developing a new chuck that almost seems to have an intelligence of its own.

The TOPlus IQ incorporates a sensor that measures workpiece clamping forces throughout the turning process and communicates that information to the CNC for automatic, on-the-fly adjustments. Users can assign different clamping forces to individual operations, such as roughing and finishing, and the chuck corrects holding power accordingly. Unlike traditional means of regulating clamping forces—namely, making manual adjustments after applying a pressure gage to the clamping cylinder or chuck jaws—the device avoids the need for operator intervention or interruptions during the machining process, says Jurgen Bettray, president of Hainbuch America (Milwaukee, Wisconsin).

The ability to adjust gripping pressure as-needed throughout the process makes the chuck ideal for clamping thin-walled or otherwise fragile workpieces, Mr. Bettray says. "As part diameter gets thinner during the machining process, some workpieces will eventually buckle if you don’t release the clamping forces," he explains. "Then, when you unclamp, the workpiece deforms back to its original position, and roundness, concentricity and other essential tolerances will be out-of-whack."

Regardless of workpiece fragility, the chuck is useful at high speeds, Mr. Bettray says. The faster the rotational speed of the chuck, the greater the outward pressure on the jaws from centrifugal forces. This factor is often unaccounted for during a job’s initial setup. Incorporating this "intelligent" chuck could enable users to both measure these forces and compensate for them in real-time.

Mr. Bettray notes that the sensor, which transmits data to the CNC wirelessly, is sensitive enough to register difference in clamping force amounting to only 1 kN. Clamping force is determined by measuring pressure on roller bearings incorporated into the interface between the clamping head and chuck body. Another notable feature is that the transmitter requires no external power supply. Rather, the required energy is generated by the rotation of the chuck.

The "intelligent" version of the chuck won’t be ready for sale to end users for some time, Mr. Bettray says. "Currently, we are testing the system with OEMs and machine tool manufacturers in Germany," he explains. "We need to develop it to a stage that it’s compatible with the various machines and controls that are out there."

Nonetheless, even without the sensor, the TOPlus clamping system offers a number of benefits, especially for hard turning and dry cutting applications, Mr. Bettray notes. Its hexagonal core is constructed of concrete polymer that reduces weight and provides a lower mass inertia torque compared to steel chucks, which can be advantageous during high acceleration. This material also improves vibration damping. Moreover, as opposed to a cone-shaped chuck, the hexagonal interface between the clamping head and chuck body ensures that all surfaces fit snugly together to create a seal against dirt and other contamination. This design also contributes to rigidity and clamping force, he adds.

Related Content

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreShop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreUsing Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)