How to Use Google Street View in Your Shop

Last week, I wrote about a shop that used Google Street View to provide a virtual tour of its facilities. I’ve recently reached out to the company to learn how they did it and see if they have any tips that might help others do the same thing.

Share

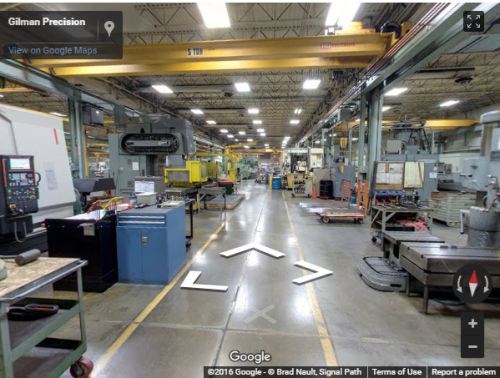

A Google Street View tour of Gilman's facility is available on its website and Google Maps.

How do you let potential customers see your machines and manufacturing capabilities when they can’t spend the time and money to leave work and fly across the country to visit your facility? Gilman Precision of Grafton, Wisconsin, is taking an unusual approach to showcasing its capabilities: providing a virtual tour using Google Street View. I wrote about this virtual tour last week, but I thought it was important to reach out to see if they would share their story and offer some tips for other shops considering a virtual tour.

Google Street View wasn’t Gilman’s first attempt at a virtual tour. YouTube videos ultimately fell short of expectations because visitors couldn’t stop and stare at things that piqued their interest. However, when the Milwaukee Chamber of Commerce sent out information for using Google Street View to tour restaurants, bars, etc., Gilman reached out to Google to see if they would consider a street view of a manufacturing facility.

To start the process, Gilman got bids from some Google-certified photographers in the area. According to Douglas Biggs, vice president of sales and marketing, prices depend on the size of your facility, and how many photos would be necessary to cover it. Gilman paid about $2,000 for photos of its 70,000 square-foot-facility.

Once the company chose a photographer, the rest of the process took little involvement from Gilman, Mr. Biggs says. The photographer used a digital camera with a fish-eye lens on a tripod to capture images around the shop. Every 5 feet, he would stop and take four photos in each direction before moving on. The whole photoshoot took about 2 hours to complete. Afterwards, the photographer loaded the tour online to Google. From start to finish, creating the virtual tour took about two weeks.

After going through this process, Mr. Biggs has some tips for other shops considering a Google Street View photoshoot:

- Consider the lighting. You want to make sure your shop is brightly lit. There is nothing worse than a dark shop.

- Clean up. While he considers it a “home-field advantage” to always have a clean shop, Mr. Biggs suggests going through and making sure to clean out your junk drawers, so to speak. Like inviting guests over to your house, you want to put your best face forward.

- Get as many sets of eyes on your shop as possible. Take several people through your shop beforehand looking for customer-sensitive parts and logos. Gilman used to be part of SFK until it set out on its own about five years ago. Still, there were some old calendars and displays that needed to be removed before the photoshoot.

According to Mr. Biggs, walking through the facility so slowly and deliberately was an eye-opening experience. “I’ve never walked my floor and examined it to that extent,” he says. “It’s a completely different way of looking at your shop. In fact, it sparked some ideas for the future. I now know that if we need a new machine down the road, we can do it by moving a certain machine to another location.”

After a little more than a week, Google Street View is already making a difference with Gilman's marketing efforts. The company promoted the virtual tour through an email blast, which saw significant growth in its open rate for that particular mailing. Moreover, the shop is already getting feedback from customers that didn’t realize it had certain capabilities. Business opportunities are already in the works.

The next step is to look at Google Analytics to see where people are clicking on the website next after taking the tour. Are they wanting more information on the company’s spindles, or perhaps they want to know about a different topic? Using this information, Gilman can better prepare its future marketing content.

Related Content

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreHow to Mitigate Risk in Your Manufacturing Process or Design

Use a Failure Mode and Effect Analysis (FMEA) form as a proactive way to evaluate a manufacturing process or design.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=300;quality=90)