Robot Frees EDM Drill From Machine Enclosure

CNC integration with a six-axis arm provides precise enough positioning to shape air- and gas-flow holes in aerospace and power generation parts.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Takumi USA

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

SpaceX — much less the commercial space industry — did not yet exist the first time Ed Beaumont seriously considered experimenting with robotic fast-hole EDM drilling. Now, he says he couldn’t have envisioned a better case study for a high-production hole making and shaping process that seems tailor-made for an era of scarce talent and supply chain tangles.

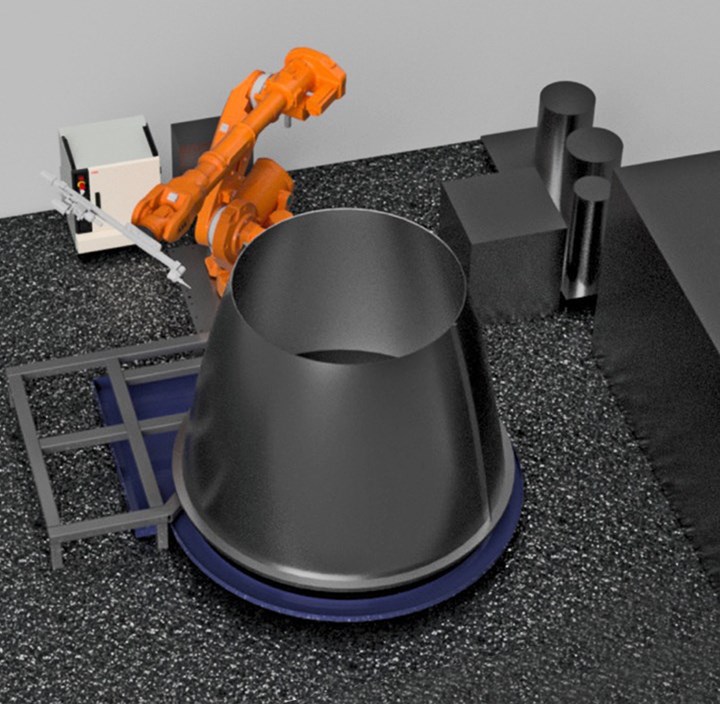

Beaumont Machine, the fast-hole EDM equipment specialist that Beaumont founded nearly 30 years ago, has supplied robots with its EDM machines before. However, there is no EDM machine at SpaceX, at least not in the traditional sense. Rather, the manipulation of the electrode is left entirely to the robot: a massive arm from ABB Robotics that maneuvers a 2-foot-long, syringe-like EDM drill around the even more massive, conical part, which spins on an 8-foot-diameter rotary table. Too large for even the largest machine enclosure, this workpiece required an alternative means of drilling the numerous holes around its diameter, which are precisely positioned and shaped to mold the cooling airflow that will keep the material intact in the upper reaches of Earth’s atmosphere.

“Robots have never really been used for EDM in this fashion before,” Beaumont says, although this is not because the task has been impossible. Rather, it has been impractical, at least until recently. Now, he hopes to see others replicate SpaceX’s success, and not just for large parts.

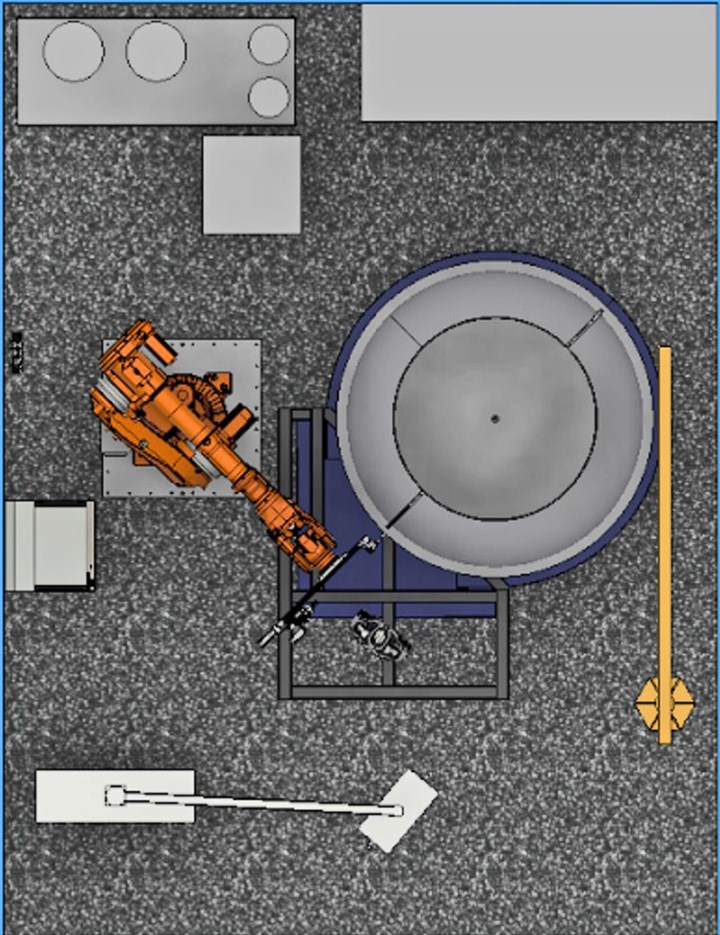

Although the EDM drilling system at SpaceX trades a machine tool enclosure for a six-axis robot, the overall system is still enclosed for safety reasons. All images courtesy of Beaumont Machine.

In fact, he envisions rows of smaller six-axis arms running all day, injecting charged, wire-thin cylindrical electrodes into nickel-based alloys and other aerospace-grade materials and pausing between cycles to swap tooling. Whatever the size of the part, robot arms can occupy less space than enclosed machine tools, are easier to replace or rearrange and have a longer meantime failure rate.

However, robot-articulated fast hole EDM is possible for reasons beyond the continued advance and adoption of robot automation. Overcoming the most significant hurdle — robot positioning accuracy — required significant ingenuity on the part of the Beaumont Machine team. The chief challenge was integrating the arm with the Siemens control system as tightly as any set of ballscrew-driven machine axes.

As seen in the 3D models, the system also relies on more than just a robot. Elements also include a rotary table; a large crane (visible in yellow); a storage station for elecrodes and guides swapped by the robot; of course, the EDM power supply. Other considerations common to any fast-hole system include water management and electrical isolation for the entire system.

In the world of EDM, the CNC control feedback loop leaves no room for the kinds of data handoffs between machine tool and robot that characterize part handling, tool-changing and other traditional applications in which the automated arm is essentially an add-on. “Putting the robot in the driver’s seat,” as he puts it, requires direct control, and for that, “there’s a lot we can do with a true interface with the CNC.”

History Repeats

Beaumont Machine is no stranger to deep CNC work. In fact, listening to Ed Beaumont explain what he is willing to reveal clarifies the extent to which the SpaceX application is an echo of the past. One example is the work of calibration and error compensation. “If you really understand how the CNC works, you can essentially program around any issues you may have,” he says.

Beaumont’s Southwest Ohio team provides EDM equipment, consumables and application engineering support to customers all over the world from the company’s Southwest Ohio facility.

CNC compensation and calibration is essential no matter how the drilling apparatus is manipulated. Peppering part surfaces with minute, precision holes requires coordinating a complex dance between the workpiece and the drilling unit, Beaumont explains. The company’s machine tools offer various means to that end, including angling heads, multiple linear axes and tilting rotary tables. Some machines even include a separate axis for manipulating the electrode itself to move along X or Y, a capability typically employed to shape the flared tapers and contours of turbine diffuser holes.

The EDM control loop can never truly be closed.

In robot-articulated applications, hole shaping depends on coordinating the arm with another means of motion, such as the custom-built, high-precision rotary table at SpaceX. Nonetheless, the same concepts apply. Given the complexity of the company’s turnkey equipment, working with a robot that can “twist any way your own arm can and also do a 360 at the end” required flexing essentially the same competitive muscles that differentiated Beaumont Machine in the first place, he says. “The way we’ve handled these challenges is what has gotten us to where we are.”

In fact, Beaumont says he had considered flexing those competitive muscles on robotic EDM drilling as early as the mid-2000s. Back then, however, the challenge would have been far greater. With modern software tools, “you can actually get the motions figured out,” he explains. “It becomes more of an X-Y-Z thing instead of ‘joint 1 and joint 2.’”

However, obtaining capability to move the drilling unit into position is not the only reason for direct CNC robot control. In EDM, Beaumont says, simply moving the drilling unit into position is not enough by itself. Precise control of material removal, particularly at the tolerances customers expect (ranging to +/- 0.0003 inch for some aerospace applications), requires a data feedback loop fast enough to provide control at the level of the material-removing spark.

The EDM Control Feedback Loop

Efforts to develop the CNC-to-robot interface mirror the company’s past work to link the other end of the control feedback loop: the EDM power supply that shapes the spark. Three years of collaboration with Siemens, which supplied the 840di CNC that runs the SpaceX system, has been critical to ensuring proper hole shapes and breakthrough rates, as well as overall process quality, Beaumont says.

The connection with the power supply matters for robot positioning because in a Beaumont system, the electrode plunges into the workpiece along its own axis (W). “The W axis is a true CNC axis,” he says. This means it can be precisely programmed to extend to a certain depth, which enables using the tip of the electrode essentially like a probe to aid in positioning. “Every time that electrode comes down it resets zero,” Beaumont explains. “We probe several points, and make the controller do the math to recenter the part.”

The SpaceX application is yet another indication that automation possibilities are expanding, and that manufacturers’ thinking must expand to match.

For robots and machine tool axes alike, feedback from these repeated “probing” cycles is critical to positioning, because the EDM control loop can never truly be closed, Beaumont says. Consider the means of material removal: a long, hollow tube that threads through a cylindrical guide, spins at thousands of rpm and provides a conduit for a stream of 2,000-psi, deionized water that flushes material through the gap between the work and the electrode tip. The control essentially attempts to maintain a the specified gap, but maintaining the gap is an inexact science because the amount of material eroded as the arc fires from electrode tip to workpiece is highly and inherently variable.

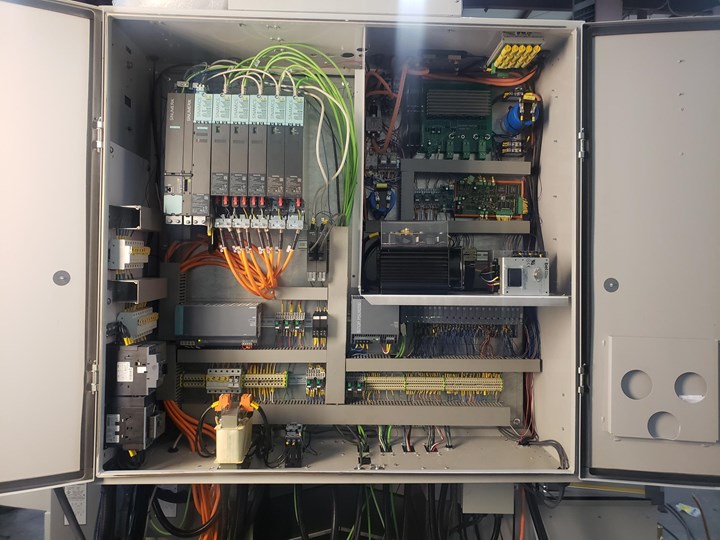

The electrical panel of one of Beaumont’s FH line of machine tools is like the rest of the machine in that it features as few components as possible, all of which are easy to source and replace.

All this adds up to the need for near-real-time dataflows from power supply to CNC to motion system, whatever the nature of that motion system. “The process is changing all the time,” Beaumont says, citing sources of variability ranging from water and electrode quality to material inconsistencies that can play unpredictably with the complex forces behind electrical material erosion. “Information has to come back to the controller in current and volts and speed and distance, and all these things have to be calculated in microseconds to pump that info back out.”

Incentive to Innovate

As for the prospect of robot arms filling similar roles in other applications, it should be noted that EDM lends itself particularly well to the process. For example, precision does not require the same level of rigidity as contact machining operations, which often rely on the mass of the machine. Nonetheless, the SpaceX application is yet another indication that automation possibilities are expanding, and that manufacturers’ thinking must expand to match.

All it took in this case was incentive. For Beaumont, that incentive included both supply chain difficulties and the chance to take the next steps toward the same goal the company has always pursued: to provide standard, modular EDM platforms that can be easily serviced from anywhere in the world, yet are also “truly made in America,” he says. When the application is right, robot articulation could be the key to limiting imported components and building a “truly great product” that is still deserving of that label.

Related Content

Kennametal Turning Tools Enhance Small Part, Medical Machining

TopSwiss Micro Boring Solid tooling and KCU25B turning inserts are well suited for the small parts and medical machining space.

Read MoreBroaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreSchwanog Custom Form Tools Reduce Cycle Times

IMTS 2024: Schwanog’s insertable form tool system supports the manufacture of precision parts for industries such as medical, automotive, aerospace and others.

Read MoreRead Next

Micropulse Technology Comes To Fast-Hole EDM

Holes in turbine blades are critical because the internal cooling airflow provided by these holes prevents the parts from overheating during operation. One of the most promising technologies for making these holes is fast-hole electrical discharge machining (EDM).

Read MoreAerospace Hole Making Takes Shape

The demand for fast hole making will intensify as more fuel-efficient jet engines are introduced. Electrical discharge machining is emerging as the answer.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)