Global Shop Solutions' ERP System Streamlines Production and Sales

Selecting an ERP software can be difficult. Finding a system that was flexible and worked with both sides of its business was important for Brunswick Steel as it switched to ERP from Global Shop Solutions.

Share

Brunswick Steel is a full-service steel production job shop in Winnipeg, Manitoba, that carries sheet, plate and long products used in manufacturing construction companies across Western Canada.

Enterprise resource planning (ERP) software is a significant financial investment, and there are many systems to choose from with a wide variety of features and capabilities. Some are designed to handle specific types of manufacturing businesses while others have the flexibility to handle almost any type of production process. As such, identifying the right ERP system for your business can require a lengthy research process. Before doing that, however, manufacturing businesses need to be very clear on how they want to operate their business and what outcomes they want from ERP systems.

For example, when General Manager Adam Plouffe joined Brunswick Steel several ago, he saw a business with one foot in the past and one in the future. The company operated a variety of modern steel cutting and processing equipment, but many facets of the production processes used outdated manual procedures. The company’s old ERP system handled the stock side of the business fairly well but it needed improvement on the processing side. Having used ERP at jobs prior to Brunswick, Plouffe convinced ownership of the need for new ERP software.

Choosing an ERP system that does it all

Plouffe’s main problem with Brunswick’s former ERP system was that “it was more of a service center software.” He says that while the software performed well regarding stock sales, it didn’t have the capabilities necessary to handle the company’s more complex, custom jobs, especially on the processing side of the business. In fact, he says financials were done in a separate system, and the system wasn’t very flexible. For example, if Brunswick had already nested a part for a specific customer, Plouffe says it was very difficult to go back and change it, add more or remove parts.

The restrictions of this software forced the company to use many workarounds, to the point in which the production team was spending about 25% of its time on administrative activities: manually recording when jobs started, how long they took, what material was used — all the stuff that ERP should automate, Plouffe says. A lack of real-time data also kept Brunswick from understanding its true capacity. For instance, “We would tell sales that we have eight hours of laser capacity available today, and six different reps would sell eight hours each,” Plouffe says. This would result in a scramble to rework the schedule, reset the due dates and keep customers happy.

In order to prevent mishaps like this, Brunswick searched for software that could manage both production processing and stock sales lines. After looking at six different systems, the company was introduced to Global Shop Solutions’ ERP software at a Fabtech tradeshow in Chicago.

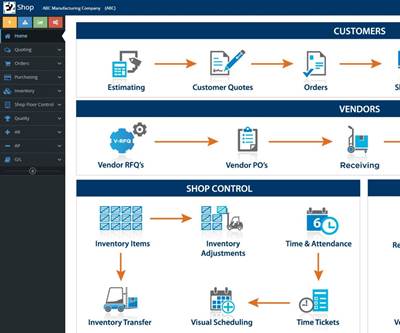

While Global Shop Solutions’ Advanced Planning and Scheduling (APS) module caught Plouffe’s eye with its ability to schedule jobs, automate purchasing supply and demand, precisely track capacity, and provide immediate financial data, it was his meeting with Dusty Alexander, president and CEO of Global Shop Solutions, during the sales process that set the system apart. Alexander told him, “If our ERP doesn’t do what you want it to, we work with you to improve it.” According to Plouffe, this was a new concept for him. “In my experience, when you get an ERP system, you use it the way you think you need to use it and don’t continue with developing or improving it,” he says. Knowing that Global Shop Solutions would add features if enough customers requested them was a refreshing contrast.

Visible improvements with Global Shop Solutions’ ERP

Plouffe says his company saw immediate improvements in its process after switching to Global Shop Solutions’ ERP system. In fact, Brunswick’s CFO emailed Plouffe one month after he first began using the system, thanking him for leading the change and noting how it was simpler to run the company’s financials through the ERP because the data is “tied together.” On the production side of the business, Plouffe says employees kept asking when they would undergo training for the new ERP system, not realizing that by not having to perform manual administrative tasks, they were already using the system as intended.

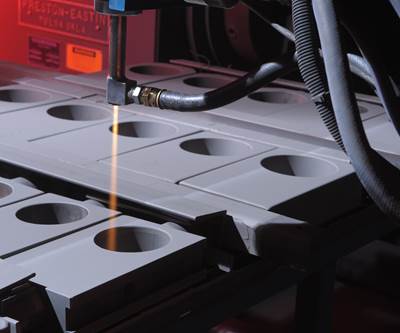

Beyond simple ease-of-use, Brunswick found that updating to a new ERP allowed it to integrate and automate processes it had previously needed to perform manually. For example, the company used to track laser cutting manually. Since integrating its nesting software with Global Shop Solutions, Plouffe says the tracking is much quicker and simpler. “Every time it cuts a part, we have actual data on each part made from the nested sheet. As with so many processes, it’s all about eliminating the time and errors involved with manual data transfer,” he says.

The APS module also provided Brunswick employees with an enhanced ability to coordinate. “The ability for sales, purchasing, finance and production to all work off the same data in real time was a huge improvement,” Plouffe says. In a change from the days of overbooking, using a master schedule has allowed Brunswick to improve on-time delivery for custom jobs and allowed it to change some stock goods from one- or two-day delivery to same-day delivery.

Advice for other companies

Plouffe advises most businesses to adopt some form of ERP. In today’s information age, you need to track how well you’re doing on a regular basis and understand your key performance indicators in as close to real time as possible, he says. However, he does caution that management should know how they want to run their business before investing in ERP. “Be prepared for pinch points during the implementation process,” he says, “but keep at it and the results are well worth the time and effort.”

In terms of Global Shop Solutions’ ERP, Plouffe says Brunswick has gotten everything it has wanted from the software to this point, and the company is still exploring all it can do. “In my opinion, the best feature is the flexibility of the software because it allows us to run the business the way we want to run it,” he says.

Related Content

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreRead Next

ERP Makes Documentation Fast, Paperless

Touchscreen interfaces and digitized part and job data are the latest examples of an aerospace manufacturer taking advantage of its shop management software.

Read MoreERP Software Gives Shop Control Over Scheduling

After relying on time cards for labor tracking and dealing with hot stickers on almost every job, Watson Grinding switched to Global Shop Solutions’ ERP software for automated tracking and intuitive scheduling.

Read MoreComparing ERP: Is the Cloud Right for You?

Make an informed decision by knowing the differences between onsite and cloud-based ERP systems.

Read More

.jpg;maxWidth=300;quality=90)