ERP Makes Documentation Fast, Paperless

Touchscreen interfaces and digitized part and job data are the latest examples of an aerospace manufacturer taking advantage of its shop management software.

Share

Although Cox Machine had the necessary capabilities and capacity to increase aerospace parts production, something had to give. More parts meant more paper — so much more paper that, in the words of Chief Technical Officer Jason Cox, “It became ridiculous. So, we decided to eliminate all paper.”

The means to this end was already in place: Global Shop Solutions’ enterprise resource management (ERP) system. Now, all document distribution and control is electronic. Rather than packets of paper, machine operators view and enter data on screens installed at individual workstations. As a result, lead times have increased, and labor hours are easier to track. The software also helps ensure first-article documentation is ready at the same time as the work.

Customizable Dashboards, Flexible Scheduling

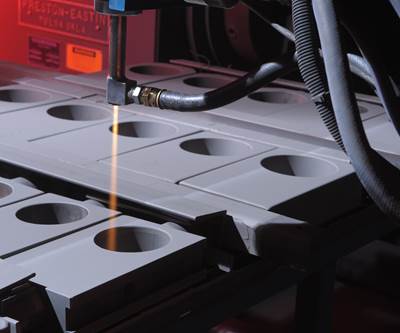

Originally consisting of four machines in a shop built from scrap material by Ernest “Bud” Cox, Cox Machine is now a 160-employee business that supplies aluminum brackets, ribs and other structural components to customers like Spirit Aerosystems, Cessna, Hawker Beechcraft and Gulfstream. ERP software, installed in 1997, provides the operational insight necessary to streamline operations across two separate facilities (an 80,000-square-foot building in Wichita, Kansas, where machining occurs, as well as a 24,000-square-foot sheet-metal fabricating plant nearby).

Cox Machine produces aerospace structures in machining cells like this one, each of which is considered a “workstation” in ERP software.

For example, the software’s flexible scheduling capabilities are particularly important. “We don’t choose our delivery dates; our customers choose them for us,” Mr. Cox says. “When we get conflicting delivery dates on large jobs, the system allows us to easily adjust capacity by adding shifts or moving people and workcenters around.”

In addition to both quick overviews and detailed, granular data on jobs and parts, the software offers a graphical overview of capacity. This is part of the “Advanced Planning & Scheduling” (APS) screen, which flexes to allow partially finite and partially infinite scheduling. This helps identify potential problems before they happen. “Looking out the first two weeks, we load up the system only for what the capacity of a machine will allow so that our dispatch lists are accurate,” he says. “But once we get a couple of weeks out, we have the ability to open it up so we can see if we have a capacity issue four, six, or even eight weeks from now.

Meanwhile, customizable ERP dashboards displayed on large screens throughout the plant help keep production on track. For example, the Customer Service Department has a dashboard with a split screen. The left side displays a customer’s inventory at their site and shows how many parts they have below their minimum inventory level. The right side lists every job that is either past delivery date or close to being there. “We have a 99+% on-time delivery rate,” Mr. Cox says. “This dashboard screen shows the 0.5% or so where we’re late as a way of helping people focus on what needs to get done.”

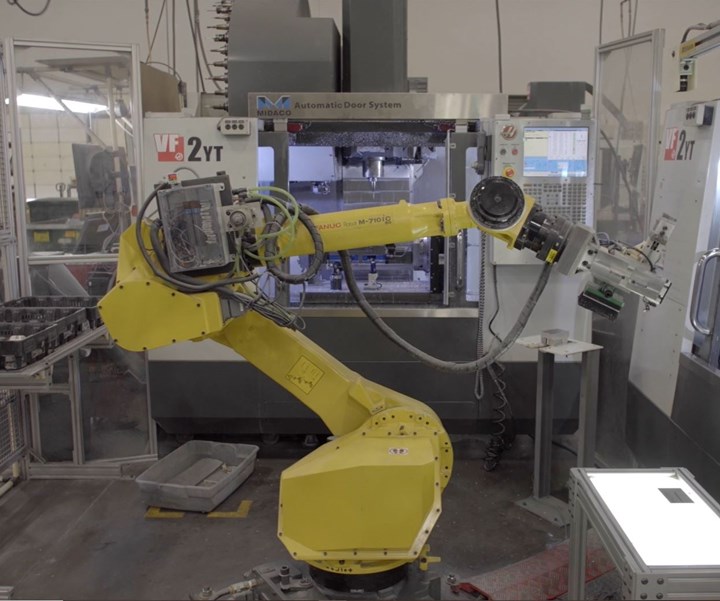

Thanks to ERP software capabilities, the shop floor at Cox Machine is paperless.

Paperless Cuts Lead Time

The decision to go paperless was a result of reducing run quantity from six month’s worth of inventory to one. This meant that the company was now creating six times as many jobs, which resulted in six times as much paper.

To avoid overwhelming the shop floor with plastic packets full of drawings, routers, specifications, part lists and more, the company installed data collection touchscreen stations at every machining cell.

Upon clocking in, operators receive the workcenter’s (that is, the cell’s) dispatch list, which shows when the previous operation was completed as well as the order of jobs that come next. Employees can access customer and part histories, first-article inspection sheets, setup sheets with workholding and other instructions; and anything else necessary to do the job without leaving their workstations.

All of this is possible thanks to the software’s Document Control functionality, which links the ERP system to more than 60 of these touchscreens. “We learned early on that the only way you can truly go paperless is for everyone to have their own station,” Mr. Cox says. “Having so many stations also helps us do other things like track direct and indirect labor more accurately. Our operators even do their own inspection at their workstations.”

As a result, Cox Machine has reduced its standard lead time for a regular machined part from 16 weeks to an average of four. It can even turn some parts in less than a week when the opportunity arises to set up a work cell with stock material already available in inventory. And in the event of a problem, there’s also a place to turn. “We’re able to get help when we need it,” Mr. Cox says. “We usually get a response either by phone or the web-based support system in a couple of hours.”

Related Content

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreRead Next

Workflow as a Competitive Advantage

As the cost of machine tools drops and the Baby Boomer generation enters retirement, the nature of competition between machine shops is trending toward data democratization and shop management software.

Read MoreERP Software Gives Shop Control Over Scheduling

After relying on time cards for labor tracking and dealing with hot stickers on almost every job, Watson Grinding switched to Global Shop Solutions’ ERP software for automated tracking and intuitive scheduling.

Read MoreManufacturing Scheduling System Keeps Shopfloor Priorities Straight

Focusing on the now rather than adhering to a plan improves throughput, allows for variation and lays a strong foundation for predictive analysis.

Read More