Share

Multiprocess or multitasking machine tools are typically thought of as machines combining operations such as milling, turning and perhaps grinding within a single machine tool. A more focused metalcutting operation that multitasking machines might also perform is gearcutting.

But when does gearcutting on a more versatile CNC machine make more sense than a conventional dedicated hobbing machine? I spoke with Mazak Senior Applications Engineer Mike Finn and Cybertec Hybrid Multi-Tasking Manager Joe Wilker to find out. We discussed the Mazak Integrex i-630V AG Hybrid multitasking machine, which is designed to cut gears through CNC milling and skiving.

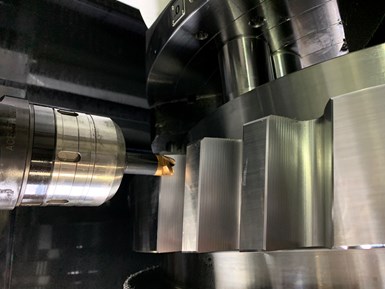

Multitasking machines benefit from being able to perform multiple machining operations in a single setup. Here, we see an Integrex i-630AG using a skiving operation to cut teeth into the ID of a part. Photo Credit: Mazak

To Hob or Not To Hob

Although dedicated gear hobbing machines are the dominant production method for making metal gears, this process has faced competition in recent years from milling and skiving as customer demand has changed. Just-in-time and lean manufacturing philosophies have led many traditional gear customers to avoid keeping large backstocks, which has led to smaller order sizes across many industries.

While hobbing is the fastest method of gear manufacturing, its economic viability is questionable for shops with high-mix, low-volume work. According to Finn, the flexibility of a multitasking machine makes up for the difference in speed. “While specialty gear machines are best for high-volume gear applications producing tens of thousands of units of a single part, the trade-off is what happens to this specialty gear machine once the job is over,” he says. “Multitasking auto-gear machines like the i-630AG can be easily changed over to a new job or even a different process.”

The reason it is so easy to change to a new job with a CNC milling or multitasking machine is simple: While a hob must be designed with the final profile of the gear teeth in mind, a single end mill can cut numerous gear tooth geometries without needing changed. The economics of scale mean that high-mix, low-volume shops will get far more use out of their tooling using CNC end mills that can cut numerous features, while low-mix, high-volume shops will get more use out of a few hobs that can produce identical gears more quickly.

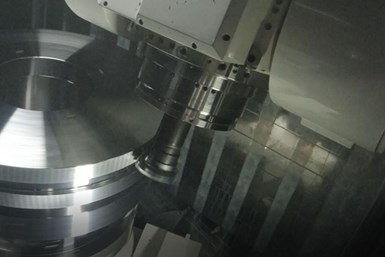

MIlling gears on a multitasking AG machine provides flexibility to the user. An end mill can be used to machine numerous features, which means they can be useful for complex parts with gear features, as well as low-volume work. Photo Credit: Mazak

Another draw to multitasking machines is their ability to fully machine parts with splines or gear teeth in a single chucking. Rather than using different machines for the gear features and the milling or turning processes, the user can produce a complete product in a single setup. This reduces the amount of time a shopfloor worker must spend loading and unloading machines, making them much more competitive in smaller batch sizes.

According to Finn, we also cannot discount the changeover between different processes. “A multitasking auto-gear machine has a quick changeover from gear skiving to gear hobbing to gear milling,” he says. “This enables users to more quickly produce complex gears with multiple features.”

Flexible Gearcutting in Five Axes

According to the company, the i-630AG is capable of five-axis machining and is designed to produce large, complex parts. Additionally, it can machine difficult materials such as hardened steel using cutting tools with a maximum diameter of 10.24 inches and max length of 19.69 inches. With large, complex gears being ideal for low-mix, high-volume work, it is well positioned for outcompeting dedicated hobbing machines in its niche.

There are other benefits specific to multitasking machines, according to Wilker. “Using a multitasking machine simplifies the programming, in comparison to using both a hobbing machine and a mill,” he says. Additionally, it enables in-process gear measurement, making it easier to avoid scrap. And according to Wilker, “Datum points can be held in relation to gear teeth with one chucking, improving part accuracy.”

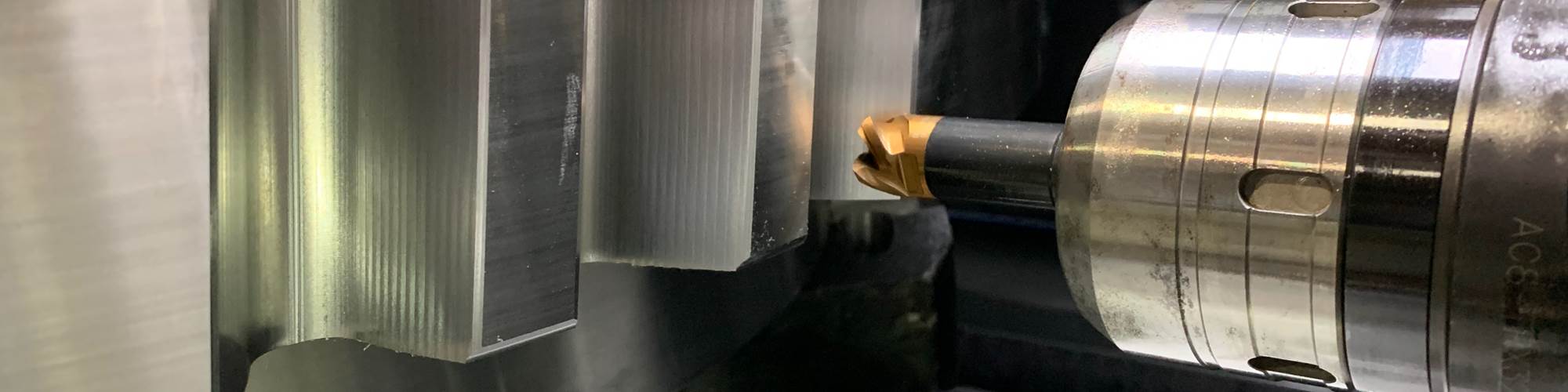

Every machine shop must make its own economic calculations on how to make purchases. For some, the batch sizes of customers’ orders can justify investing in a dedicated hobbing machine. However, the flexibility of being able to skive the OD while milling complex features without changing machines will appeal to others. Photo Credit: Mazak

Both the C and B axes are monitored in the i-630AG using rotary-axis scale feedback, and both are synchronized to prevent fluctuations in the spindle speeds from producing out-of-spec parts. The machine uses Mazak’s Mazatrol SmoothAI control and includes Smooth Gear Cutting software, which automatically adjusts cutting parameters if either the milling or turning spindle drifts away from the target speed. “Thanks to the machine’s synchronization, we’ve increased productivity,” says Wilker. “Additionally, heat-treated materials can be cut with carbide cutters and cut small-to-large / heavy-ID or -OD gears based on machine models.”

According to the company, the machine’s control is designed to enable the user to completely program a job at the machine, rather than offline or at a dedicated CAM system. “This lets users create a part program in its entirety, including turning, drilling, milling and gear-tooth machining on the machine control without additional software and without a part model.” For users nervous about programming entirely on the machine control, each gear-cutting module can be verified through toolpath simulation accessible on the control.

For a machine shop, it is dangerous to rely on old orthodoxy when it comes to growing the business, as we can see with this machine. While experience can guide shops well, it is important to dispassionately interrogate the way parts are processed and decide if that is still the way forward. Where once productivity and precision were the only measures of a machine’s value, it seems that more shops are performing this calculus and concluding that flexibility is vital to their success.

Related Content

Industry Analysis: Machining Semiconductor Components

With many machine shops anticipating long-term growth in demand from the semiconductor industry, it is worth the time to heed the advice of manufacturers who have already been servicing this end-market for years.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreCustom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

Read MoreMultitasking Machines Cut Days From Shop’s Setups

Adopting WFL Millturn machines enabled BWXT to condense operations and setups while also providing a simple way to simulate and secure processes.

Read MoreRead Next

A Job Shop Approach to Automation

Through patient research and smart investing, this job shop has slowly grown its capabilities and is moving toward lights-out manufacturing for prototype work.

Read MoreAn Introduction to Superfinishing

Learn what superfinishing is, what applications it should be used for and why you should take care when specifying surface finish parameters.

Read MoreSurvey Sees Machine Tool Buyers Seeking to Reduce Costs and Add Operational Flexibility

The 2021 Metalworking Capital Spending Survey from Gardner Intelligence shows overall purchasing declines but increased investment in higher-end machine tools such as turn-mill machines and five-axis machining centers.

Read More

.jpg;maxWidth=300;quality=90)