Share

“Everybody was doing the right thing, but somehow we still weren’t making any money.”

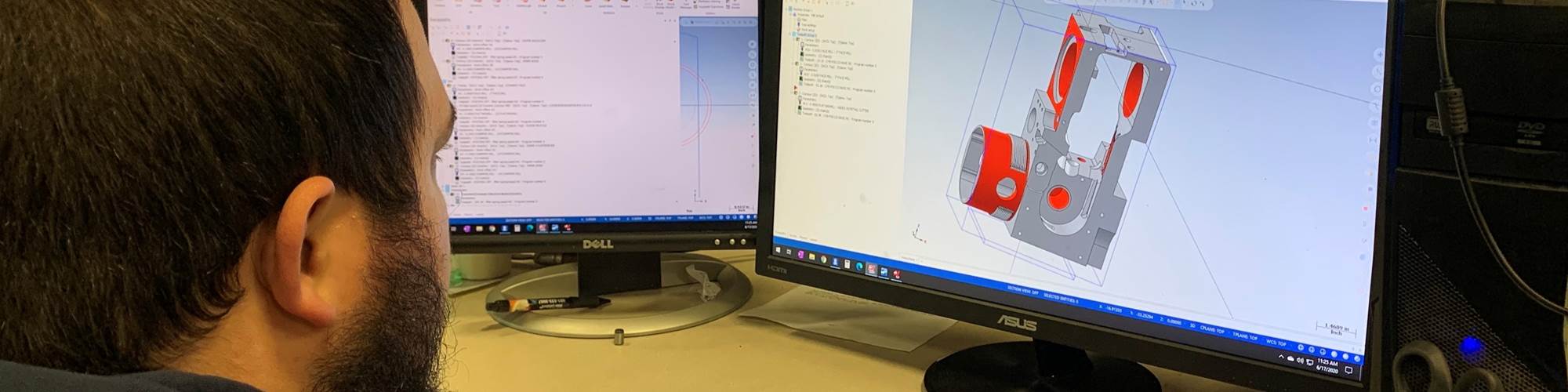

Automatic ballooning and report generation dramatically speeds the creation of documents essential to the work of Chris Kancel-Lengyel, quality control inspector. All Photos: Marzilli Machine Co.

Job shop owner James Marzilli was discussing a specific job when he said this, but the problem was bigger than any single project. One lesson of this Boston area manufacturer’s recent, rapid growth is that mismanaged inventory, lack of standardization, documentation errors and other systematic inefficiencies that do not always show up on a balance sheet can have as much impact as anything happening on the machine tools. “Everybody is talking about automating, but what they’re really saying is just, ‘Let’s put a robot in front of this and replace the person,’” Marzilli says. “They’re not really considering how much manual work goes into just administrating the company.”

Software automation has impacted the work of the entire Marzilli Machine Co. team, from management and office staffers to machinists and other shop-floor personnel. As of this past spring, various company meetings were focused largely on redefining the roles of office personnel who found themselves suddenly free of hours of busywork, particularly tasks associated with inspection plans and reports. On the shop floor, paper travelers are no more, replaced by digitalized work instructions and point-of-collection data entry. Planning, programming, and even tool purchasing and assembly are conducted more efficiently and further in advance than ever before.

As of this past spring, this transition was still ongoing. However, Marzilli hopes the new way to be fully in place by the time social distancing requirements relax. A few large, well-known OEMs have already expressed interest in visiting the shop, and his team aims to impress. “We’ve been all-hands-on-deck getting everything turned over into the new systems and figuring out how we are going to start processing all of our jobs digitally,” he says.

Work Without Busywork

Housing 18 employees and nearly 20 machine tools, Marzilli Machine’s roughly 5,000-square-foot facility is cramped. Nonetheless, capability to accommodate new work has been limited more by the time and effort required to manage it than any constraint on space or machining capacity, Mr. Marzilli says.

“It was death by a thousand papercuts.” – James Marzilli, Marzilli Machine Co.

Even with a clear path to growth — one made easier by HUBZone certification from the U.S. Small Business Administration— the best opportunities have tended to require more clerical work, he explains. Traceability requirements for the target work are strict. Every measurement must be carefully planned and thoroughly documented to comply with demand for Production Part Approval Process (PPAP) requirements, ISO 9001 quality standards, and AS9100, a quality certification that the shop likely will have earned by the time this article is published. “It’s way too much work for one or two people to manage if you want to scale,” he says.

Christian Zapata, machinist, blows chips from a setup on one of the shop’s vertical machining centers.

One task that can be particularly burdensome is notating drawings — that is, hand-drawing balloons and marking features and tolerances on part blueprints for use in inspection plans and reports. Overall, Marzilli estimates that this process took one person an average of two days per week. Upon seeing a customer’s print that stood out for its crisp, obviously computer-generated ballooning, the team began investigating available software. The eventual choice was High QA’s Inspection Manager system, a software package that uses optical character recognition technology to scan paper or PDF prints and identify features. It then fills in all the balloons and populates reports with the relevant data. “If it’s a modern drawing with a modern font, it takes about 30 seconds to assign a bubble everywhere it sees a dimension,” Marzilli says.

Much of the shop’s work cannot be photographed. One exception is this support bracket for a precision medical device, which was machined from a single block of aluminum in multiple operations on a three-axis VMC.

From there, inspection planners make any additional notes required for the job and check the print for errors. Upon approving the print and deciding how each feature should be measured, inspection planners can output step-by-step instructions, information on tools, and other inspection plan data in any number of standard formats. The case is the same for the format of reports documenting the inspection results. “First-op inspections, second-op inspections, AQL-level inspections — it generates whatever documentation we need to do the job properly to aerospace standards,” he says.

With no worries about generating additional work for themselves, quality personnel are free to plan additional in-process inspections. Counting fast cycles as a given, he says stopping for first-, second- and third-op inspections is worth it for the sake of ensuring greater confidence in machining complex geometries from high-temperature alloys. The company is also free to pursue more work requiring first-article inspections and/or complete inspections of every part. As a result, he estimates the shop is processing twice as many jobs since before the software was installed.

Prior to automating the process with software, prints like this one had to be “ballooned” – that is, filled in with geometric dimensioning and tolerancing (GD&T) information relevant to specific features – by hand.

Automating ballooning and other tasks associated with inspection documentation enables scheduling more inspections to improve quality and meet more stringent customer requirements.

However significant, these gains only whet the teams’ appetite for more. What other tedium could be automated by software, and why should software automation be limited to quality control? “We started to think maybe we should look at everything like this — that maybe everything we had been taking for granted as needing to be done was just wrong,” Marzilli recalls. “We started to think maybe we could run the whole company this way.”

Closing the Loop

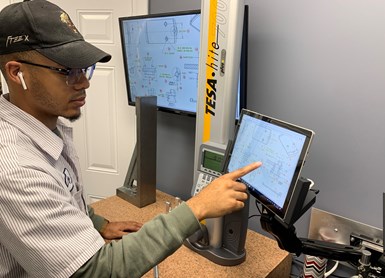

The new thinking embodied by Inspection Manager led directly to the next addition to the shop’s digital infrastructure:Proshop ERP. Travelers – paper packets of job information that move from workstation to workstation — are no longer necessary. Rather, shop-floor employees take direction from individual displays at each workstation that broadcast step-by-step instructions, complete with pictures of setups and hand gages and other needed items, tailored to that particular stage of the process. Rather than filling out inspection reports by hand to be scanned into a PDF later, employees enter the data at the point of collection into digital interfaces at each workstation, checking each task as complete before the system advances to the next.

“Our old process was not designed around planning jobs; it was designed around executing them. Now, we focus on planning, and the execution happens on its own.” - James Marzilli

If a part feature is out of specification, or even if the data is in an unexpected format for the task at hand, the software issues an alert. Depending on the situation, the user might then be prompted to create a material noncoformance report and asked whether to notify others of the situation. Anyone notified in this way can access all information about that job through a hyperlink from any Web-enabled device (although Marzilli emphasizes that access to sensitive information is restricted outside the shop).

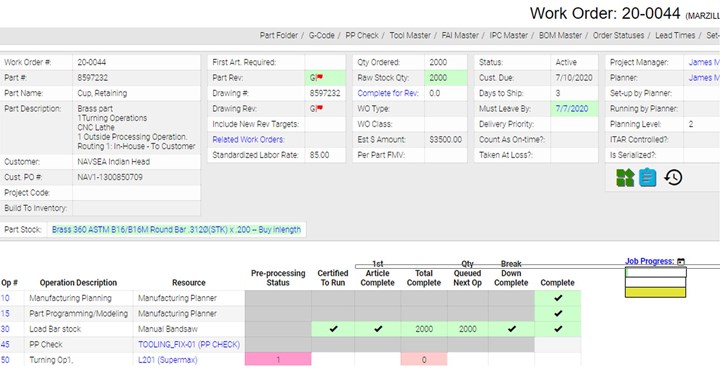

Such easy access is possible because the system runs in a Web browser. In fact, hyperlinks are the primary way of navigating the information for any given job. For instance, the bill of materials section might feature a link to a purchase order for consumables as well as information on when it was received, when it was inspected, any certifications, and the location in the shop. Color-coding can reduce the need to drill down for such information, Marzilli says. For example, blue indicates that material has not yet been ordered, but a person has been assigned to make the order. Yellow indicates the order has been made, and green indicates the material received.

Hyperlinks, shown in blue on this portion of a work order, are the primary means of navigating about the new ERP system. Other color-coding makes information easier to digest.For example, green highlights indicate needed material has been received, while yellow highlights indicate a new work order has been planned and tools are ready to be staged.

However, he emphasizes that jobs are planned and organized not by work order, but at the level of individual parts. This makes traceability easier in the event of questions about, say, which hand gage measured which part feature, when that gage was calibrated and who conducted the measurement. He adds that individual part design revisions no longer require copying the entire work order. Once approved, the new print is entered into Inspection Manager like any other, setting off a cascade of activity driven by that software and ERP with little effort from shop personnel. “The office administrator puts in the new, approved print and balloons it, and the quality control manager gets a message saying, ‘There’s been a revision to the print, please update the inspection planner,’” he explains. “The inspection planner gets a message saying, ‘Please make sure the programmers are up to speed.’ All this stuff just queues up automatically.”

Focus on Planning

For employees like Brandon Gervasio, machine operator, digitalization makes locating items in the new tool crib or anywhere else in the shop is easy.

With a broader focus for digitalization than quality control, Marzilli Machine’s processes continue to evolve. One of the most recent and significant changes involves tool inventory management. That is, the shop now has a tool crib. Within, the thousands of tools the shop has built up over the years are no longer organized by type and size, as they once were. Rather, bins are labeled in seemingly random fashion. Tools must be checked in and out through the ERP system, where each is associated with a photograph and an identification number denoting its location. “There’s no more searching,” Mr. Marzilli says. “You just query ERP right from your workstation, then go to the bin it tells you.”

The organization of the tool crib might seem random, but the new ERP software makes needed items easier to find than ever before.

Purchasing is also based on demand, rather than a simple “fill the drawer when it’s empty” strategy, he adds. CAM programs are developed as soon as inspection plans are complete, at which point Proshop scans the G-code and determines which tools are required to machine the part. Based on tool life estimates, the software might determine that there are not enough and prompt an order for more. By the time machining begins, all tools will have been assembled and preset in the tool crib, a contrast from the previous practice of having operators do the work themselves. “We can tool up a 15-tool job in 10 to 20 minutes, which is down from 45 minutes or even an hour in some cases before,” he says.

Marzilli Machine’s new digitalized process illustrates more than just the advantages of the software packages. It also demonstrates how the Marzilli Machine team has come to think differently about manufacturing in general. “Under the old way, we’d sometimes order tools the day the material was being cut because maybe someone had turned down what we thought was a half-inch countersink,” he says. “It was death by a thousand papercuts.”

Eliminating those cuts has enabled this small shop to find capacity where none existed before. “Our old process was not designed around planning jobs; it was designed around executing them,” he explains. “Now, we focus on planning, and the execution happens on its own.”

Related Content

Building Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreManufacturing Madness: Colleges Vie for Machining Title (Includes Video)

The first annual SEC Machining Competition highlighted students studying for careers in machining, as well as the need to rebuild a domestic manufacturing workforce.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreRead Next

Four Keys to Establish a Digital, Paperless CNC Machine Shop

Paperless digital workspaces can help CNC machine shops save money and improve workflow through improved internal connectivity, but getting there requires the right tools and careful strategies.

Read MoreERP Makes Documentation Fast, Paperless

Touchscreen interfaces and digitized part and job data are the latest examples of an aerospace manufacturer taking advantage of its shop management software.

Read MoreManufacturing Scheduling System Keeps Shopfloor Priorities Straight

Focusing on the now rather than adhering to a plan improves throughput, allows for variation and lays a strong foundation for predictive analysis.

Read More