Open-ended survey questions yield answers that do not lend themselves to tabulation or strict statistical analysis. Nevertheless, the results can be useful and revealing. They are especially valuable as an indication of what ranks as a high priority in the respondent’s mind. Therefore, reviewing the answers is a matter of noting patterns and interpreting their meanings.

Our “Top Shops” benchmarking survey asked this question: What one strategy or technology has had the biggest influence on your success? About 40 percent of the survey respondents offered their unprompted comments. Most of these were very brief and to the point, suggesting assuredness in their formal answer.

Overall, the most striking characteristic of the responses is their diversity. Although it is significant that several technologies and strategies emerged, there was no clear winner or broad consensus indicated by the results. During the development of this survey, we speculated whether a “silver bullet” might emerge as the one strategy or technology most capable of striking down the usual barriers to productivity and profitability. No such cure-all emerged. However, it is clear that shops have distinct views of what is most important based on their own experiences.

Lights-Out Machining

The term “lights out,” as in lights-out machining, appeared most frequently in the responses. Including responses that mentioned the terms “unmanned,” “unattended machining” and “24/7 operation,” approximately 10 percent of those who answered this question referred to this method of operation.

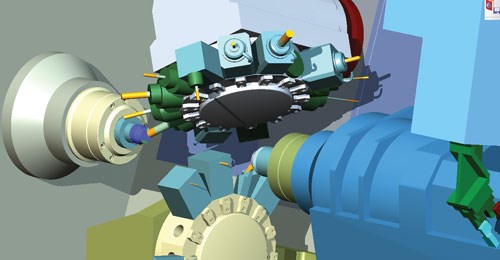

Lights-out machining requires organization, preparation and automation. A shop must devote its workforce to preparing its machining resources for maximum productivity when they are absent. This means readying workpieces, cutting tools, CNC programs and more for “unstoppable” operation during long periods when human intervention is unavailable. Finally, hardware and software systems must have the capability to operate on their own.

These requirements are reflected in the following survey responses:

• “By buying high speed machinery with broken-tool detection and automatic measure-ment systems, we can run jobs/machines unmanned.”

• “We are currently undergoing several automation projects to enable better spindle utilization through unattended lights-out machining. We have invested significantly in equipment and human resources in order to make this leap.”

• “We are operating 24/7 with only one day shift.”

A number of respondents cited “automation” but did not specify what form it was taking in their shops. These answers are probably best summarized by the spirit reflected in this comment: “We are adding automation and doing more with less.” Survey results show that Top Shops are more than twice as likely to use machine-tending robots as other shops (10.1 versus 4.1 percent.)

High Speed Machining

At least a half-dozen respondents specifically mentioned that high speed machining has the biggest influence on their success. This is significant because high speed machining is also the machining strategy most often cited as employed by all shops taking the survey (46.6 percent) and by the Top Shops (54.1 percent).

High speed machining does not have a precise definition, but it generally refers to techniques for achieving high metal-removal rates with quick milling passes. High speed machining is applied in different ways in moldmaking, aero-space and production work, but implementing the strategy almost always represents a distinct “break from the past” for the shops that have adopted it.

Like lights-out machining, high speed machining calls for a disciplined, rigorous approach that is a challenge to shop management as well as shopfloor personnel. The far-reaching effects of high speed machining are invoked by these two representative comments:

• “High speed machining/faster spindles and tool changes have made a significant difference in profitability.”

• “The high speed machining techniques I have picked up have boosted every aspect of my shop.”

It is not surprising then, that high speed machining would be associated with top-performing machine shops.

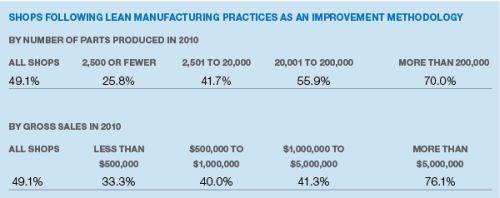

Lean Manufacturing

The survey shows that 72.2 percent of Top Shops and nearly half (49.1 percent) of all survey respondents are following lean manufacturing as an improvement methodology. As might be expected, a number of shops claim that lean manufacturing has had the biggest influence on their success.

Here are some of the comments:

• “The implementation of a lean management system has dramatically improved our competitive edge.”

• “Even though we are 12 years into lean, it continues to remove waste and contribute to the bottom line.”

• “We are focusing on increasing job profitability and efficiency while reducing lead time through efforts such as kaizen events.”

It is significant that each of the statements links lean with an important economic benefit. Lean manufacturing helps shops make money.

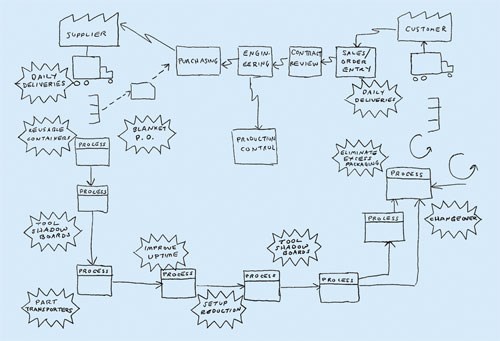

Lean manufacturing was originally developed as a methodology to make a production process (building automobiles at Toyoda plants in Japan) highly efficient. Applying some of the most important elements of lean manufacturing in the job shop setting has therefore been problematic. For example, it is difficult to create valid

value-stream mapping when the highly variable work in a job shop creates a moving target for lean implementers to capture. (Only 10 percent of surveyed job shops report practicing value-stream mapping.)

Nevertheless, a study of the survey data shows that 41.7 percent of the respondents who identified themselves as job shops are following some form of lean manufacturing. This may be at the basic level of 5S workplace organization, however. About 27 percent of surveyed job shops do 5S. Notably, 54 percent of the survey’s Top Shops are practicing 5S.

The table below shows that lean manufacturing is more prevalent in larger shops.

CAD/CAM Software Counts

Several respondents pointed to CAD/CAM software as the technology with the biggest influence. In fact, most of these comments named the specific software product that made a difference. This is perhaps an indication of how important design capability or programming features from a certain developer are in a shop’s perception of its success factors.

For example, one shop cited a CAM package for its help in “dealing with challenging parts (geometry).” Another shop pointed out that its 3D design software “helped us upgrade our design and quality functions.” For another shop, a particular roughing program merited mention because it “cut cycle time and increased tool life.”

Customer Focus

A few thoughtful respondents turned this question around to say that neither a strategy nor a technology had the biggest influence on success. Rather, it was a matter of customer relations. Consider these representative comments:

• “It is important to retain customers but always deliver quality and on-time product regardless of job performance or profit.”

• “Being friendly, personable and honest is important. It is also important to be ready, willing and able to do whatever the big customer needs—and be honest when I can’t do something.”

• “Working with the customer to redesign for lower cost-to-manufacture parts is our key to success.”

Making the Investment

Regardless of the technology or strategy indicated in the various responses, a willingness to invest is implicit in many comments. Frequent action words in the statements are “investing,” “upgrading,” “purchasing,” “buying,” “adding” and “replacing.”

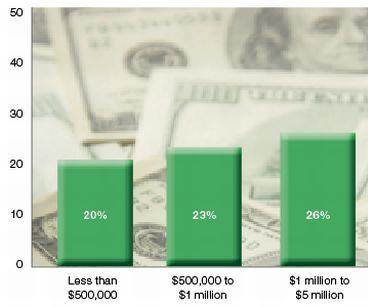

Survey results show that Top Shops invest more heavily in capital equipment than other shops. These heavy investments equaled 10 percent of sales for 2010, on average. These shops are also likely to maintain or increase this level of investment in 2011.

Investment, of course, reflects a faith in the future, and that is perhaps the one big thing every shop needs in order to succeed.

.png;maxWidth=45)

.png;maxWidth=150)