Die Manufacturer Embraces IIoT to Move to Shorter-Run Production

As a punch and die supplier’s customers implemented leaner strategies, it needed to shift to shorter-run manufacturing. An ethernet communications system enabled machine CNCs to communicate with bar feeders to automatically switch part programs without operator intervention.

Share

American Punch Co. (Euclid, Ohio), a punch and die supplier for both heavy-gauge stamping markets like construction and smaller-gauge markets like automotive, has to stay apace with its customer base. This has meant shifting from large-volume production to effectively machining smaller runs with shorter turnaround times in order to meet just-in-time delivery orders demanded by its customers’ implementation of lean strategies. As one would expect, adapting to these demands has created its own set of challenges, including finding ways to keep costs down despite the potential for increased labor involvement.

Faced with these issues, production engineer Brian Cain began re-evaluating the company’s manufacturing processes in 2012. A visit to the International Manufacturing Technology Show (IMTS) that year put Mr. Cain in touch with LNS, whose e-Connect system introduced American Punch to the Industrial Internet of Things (IIoT) as well as a way to automate program switches between bar feeder and lathe.

Searching for a Way to Move to Shorter Production Runs

While American Punch’s high-precision punches and dies were well-received by its customers, its manufacturing process was geared to standard production practices that produce hundreds of a single part, rather than the smaller lots of five,10 or 20 pieces increasingly demanded by customers.

“Short runs like these require multiple setups and increased attention from the machine operator which, of course, adds time and labor cost to the parts,” Mr. Cain says. “An alternative is to make longer runs and stockpile the finished products until the customer wants them. Although we do stock a number of high-turnover parts for certain customers, adding many of these lower-volume parts ties up additional working capital, requires more floor space and increases our work in process. So, I began looking for ways to make these small-volume runs more efficient. We were already using an automatic bar feeder to load material into our CNC machines, which worked well for high-volume production but not for the shorter runs our customers wanted. Each time we changed to a new part meant calling up another program on both the turning machine and the bar feeder.”

Encountering a Solution at IMTS

Mr. Cain had decided that the ideal solution would involve ganging together a family of similar parts that had a variety of lengths and characteristics, and then run them all at the same time with one setup. However, no one he spoke with at the trade show could come up with a good way to run multiple parts from barstock in a single setup.

Then he visited the LNS America Inc. booth and discussed his needs with systems software and control manger Randy Lewis. They discussed the e-Connect ethernet communications system, which enables the bar feeder and CNC machine control to share data.

When e-Connect and the machine tool CNC “talk” to each other, the former can look at the production schedule upon completion of a part run in order to select the next part to be produced, then hand off this data to the bar feeder. The bar feeder consults its internal part library that stores all of the bar-feeder parameters for as many as 500 part programs, selects the program that matches the one chosen by the master schedule, then automatically adjusts itself to the new program.

This was exactly the solution for which Mr. Cain was looking. “I learned that we were on the ground floor of this kind of data sharing that’s now becoming more widespread,” he says. At that time, Mr. Cain’s machines were not ready to share data, so LNS worked with American Punch’s machine tool supplier and the original equipment manufacturer to get them up to speed.

Putting Machine Tool Connectivity to Work

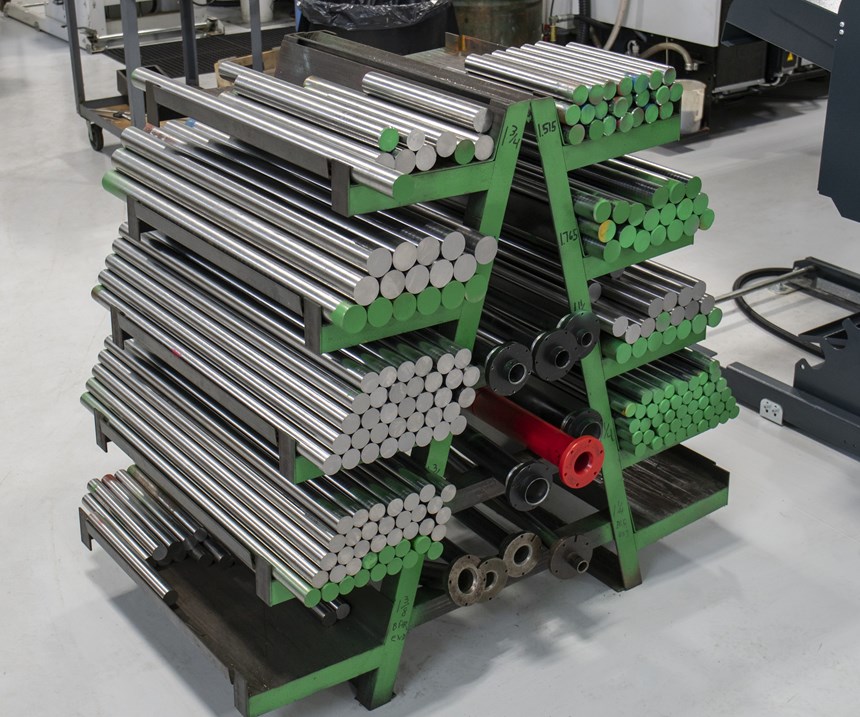

In that application, the e-Connect system resided in the LNS Quick Load Servo 80 S2: a spindle-length, all-electric, servo-controlled, fully automatic bar feeder that loads 14- to 63-inch bars with diameters ranging from ¼ to 3 1/8 inches. The American Punch machine operator would load the bar feeder with 1 ½-inch tool steel barstock and run a macro program that enables the lathe control and bar feeder to change from one family of parts to another on the fly.

A typical setup would include loading the appropriate-diameter barstock to make various quantities of different lengths of parts. For example, it would use 1 ½-inch-diameter bars to produce 50 parts measuring 2.500 inches long, 10 parts measuring 3.025 inches long, 75 parts measuring 3.500 inches long and so on. The parts could vary in form, as well. This setup enabled unattended, even lights-out production on short part runs.

Today, with four work cells using the LNS e-Connect system and bar feeders, American Punch runs more than 300,000 parts each month and is in the process of adding additional capacity to meet customer demands. The newest work cell consists of an LNS Quick Load Servo 80 S2 bar feeder loading barstock into a Doosan Puma 2100SY turning center capable of milling, drilling and tapping. In addition to interfacing with the LNS bar feeder, the machine’s CNC also communicates with a programmable high-pressure system to apply the precise amount of coolant for each machining operation.

Another benefit of the e-Connect system is reduced material waste. In addition to storing the bar-feeder parameters for each of the part programs, e-Connect tracks material usage and communicates this information to the machine tool. The master schedule looks at the amount of available material and the lengths of parts in the production queue to determine if there is enough material to run the required quantity of a particular part. If there is not enough material for the entire run, the system determines the length of any remnant, calls up the next part in the schedule that fits the remaining stock, and the lathe and bar feeder automatically adjust to make the new part. Once the bar is used, the bar feeder loads the next bar and the system repeats the process until it makes all of the scheduled parts.

“These work cells have made a significant improvement in our cost-per-part through unattended operation and by adding a labor-free overnight shift,” Mr. Cain says, adding, “We not only solved the time-to-delivery issue, we’ve expanded our capacity to take on additional work.”

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreManaging Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Read MoreFour-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)