For This Machine Shop, Licensing Is the Answer to the Inventor’s Dilemma

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreMachining frequently involves invention. Independent machine shops are not mere producers; the work is not that simple. Job shops involved in prototyping often help customers refine and complete their ideas, and job shops also routinely invent the clamping and gaging devices that aid their own work. For the tool shop, the link between machining and invention is magnified — every custom tool is arguably an invention. Invention is so inherent to the work of machine shops that they sometimes invent or see inventions with usefulness to other manufacturers.

What should the shop do when this is the case? How should it advance the idea? A machine shop is not in the business of product development or marketing — pursuits separate from the work the shop’s owner and team have chosen, and do well.

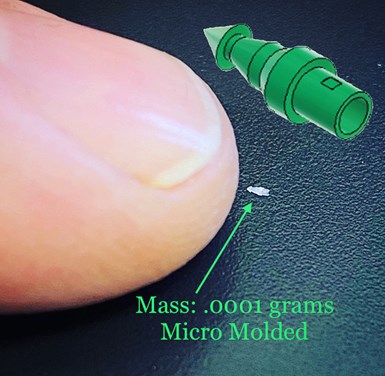

The solution developed by machine shop and moldmaker M5 is this filament-fed molding machine for producing small and precise plastic parts. Photos courtesy of M5.

Jon Baklund faced this challenge. In fact, he expects to face it again and again. The owner of Minnesota Micro Molding, Machining and Manufacturing (M5) is a toolmaker and inventor who wants to keep doing the latter while remaining focused on the former. An invention he and his team have been working on over the course of eight years, and have now proven and provided to customers, is a desktop micromolding machine that provides a repeatable, cost-effective way to mold plastic parts with shot sizes in the tiny range of 0.0005 to 0.1 gram. To advance this technology, Baklund aims to make the system available by licensing it. Rather than making machines and selling them, his company will offer access to the idea to any company that wants to secure the right to make the molding machine for its own use.

Baklund’s own business has seen ongoing invention. M5 began as a general provider of specialty tools and parts. Over the years, we have tracked the shop’s exploration of technology. The shop ultimately found a niche in micro-scale machining, including micro moldmaking. This work led to close relationships with customers developing tiny parts, particularly medical device makers, one of which wondered if there was not a more material-efficient way to mold tiny parts. Baklund suspected there was, and he could never quite let the idea go.

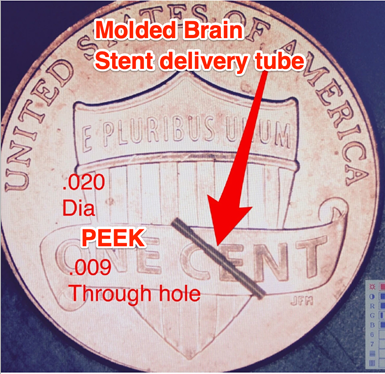

The shop created this image and the one following to show and describe some of the applications of the micromolding system.

Material efficiency is a challenge of micromolding because of the scale of material waste compared to the tiny mass of the parts. An injection molding machine’s screw contains material that has to be purged, and runners between cavities of a mold produce waste that is large relative to the parts. All this material loss can multiply the unit cost of the part when its dimensions are small. Is it possible to micromold in a way that converts a higher proportion of material into sellable product?

M5 specifies the machine for shot sizes down to 0.0005 gram, but has used to mold parts successfully at smaller sizes as well.

Baklund’s small molding machine does not use a screw to extrude material; instead, it is fed by plastic filament. The filament advances in precisely controlled increments into a mold that is heated. Small gates connect the filament to micromold cavities, but except for this, all of the material entering the machine becomes parts. An early production application shifting from a conventional screw-fed micro injection molding machine to the M5 “iE” (for Intelligent Energy) molding device realized material savings of 75%, along with a 50% increase in production rate due to shorter molding cycle times.

The machine is working now; it is ready to sell. The idea is patented. But now that all this is the case (now that the invention is done), Baklund finds himself in the predicament that other machine shop inventors might recognize. He does not want to become a machine builder — this would consume energy and take free attention away from pursuing whatever proves to be the next invention, not to mention the toolmaking work the business is good at. And he does not want to completely sell away the idea, in part because removing himself as an advisor involved with the machine’s applications limits how sellable the idea is, and therefore limits the price he can sell it for. All he really wants is to see the idea flourish and to be compensated for his time in developing the idea. A license fee allowing others to manufacture the system accomplishes this.

The license the inventor is offering is site-specific. Licensees are free to produce the machine for micromolding at a given location.

Each license is tied to a site. The company purchasing a license is free to manufacture the M5 iE for use in that site. “A company with toolmaking ability and micromachining capacity should be able to do it,” he says. The licensee might also hire his shop to make the machines, but this is not required. The license is purchased through a one-time fee and lasts forever. Baklund expects to set the fee at $25,000.

For a business focused on manufacturing, selling the rights to others to do the manufacturing might seem counterintuitive. But again, Baklund does not want to see M5 become a machine builder. Producing a standard product inevitably has to also connect closely to marketing, selling and supporting that standard product. There is a reason why OEMs and machine shops both exist, and why the former contracts with the latter. To stay true to the work of a machine shop, but also share his invention, the shop owner had to get inventive about the way he took it to market.

Related Content

Grob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreCimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreLyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)