Deep Hole Drilling Without Drift

A deep hole drill with intuitive controls and minimal hole drift was one shop's pipe dream — until the shop helped a machine tool builder make it.

Share

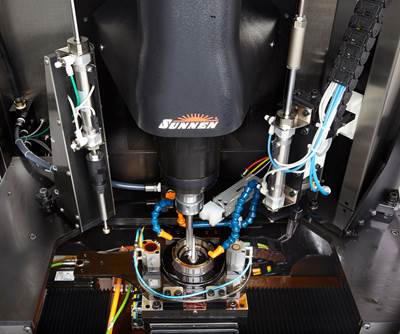

Sunnen’s SHDD-4500 can solid drill inner diameters between 0.8 and 5.0 inches and perform counterboring or trepanning on inner diameters up to 7.0 inches, with Midwest’s general manager, Tom Huiras, saying the machine stays accurate at any hole size with minimal hole drift. All images courtesy of Sunnen.

The cylindrical workpieces coming off Midwest Precision Manufacturing’s Sunnen SHDD-4500 deep hole drilling machine bear a distinct difference from the deep hole drilling work the shop is accustomed to. On parts from the Sunnen machine, it is extremely difficult to tell which end is the entrance and which the exit. Beyond this higher standard of hole alignment, the SHDD-4500 has also shortened Midwest’s cycle times and streamlined deep hole drilling programming compared to the shop’s other deep hole drills.

Midwest Precision Manufacturing is a job shop that performs deep hole drilling, precision gun drilling and precision honing for a wide array of customers, with a special focus on those in oil and gas, die casting or the medical industry. The company has also been softening its customers’ supply chain issues by running replacement parts for steel mills and steel hoses.

The SHDD-4500 has been key to keeping Midwest’s lead times low since its arrival in December 2020. This machine is one of few that is genuinely tailor-made for a shop’s purposes — as Midwest was one of 10 shops to provide feedback on the machine while it was in development, contributing to the final design.

Hole sizes have held at ±0.005 inch, according to Huiras, with hole drift at less than 0.001 inch per inch drilled on the SHDD-4500.

This machine was honing technology provider Sunnen’s first foray into deep hole drilling, so Midwest consulted on the challenges and requirements of deep hole drilling. The shop then tested the mechanical reliability of Sunnen’s prototype vibration dampers and chip conveyors to ensure the final machine would be compatible with the steady stream of Inconel, titanium, 4140 and 8620 steel workpieces Midwest regularly drills. Midwest senior team leader Chris Braby also played a significant role in the design of the Sunnen machine’s control.

On-Machine Database

“Older drilling systems require a degree of operator expertise, and that takes a lot of training,” Braby says. As such, he worked with Sunnen to ensure the deep hole drilling machine’s control would streamline the operator experience and make the machine easier to run.

Key to streamlining machine operation was enabling the control to save individual part numbers’ speeds and feeds for later access via drop-down menus. This enables new employees to make use of more experienced personnel’s knowledge by saving time on repeat jobs or using successful parameters as starting points for similar parts made from the same material.

Midwest was able to improve its drilling speeds and feeds between 20-30% for parts on the SHDD-4500 compared to parts on its older drilling machines.

(W)hole Machine Stability

Aside from the control, Sunnen and Midwest prioritized stability and accuracy for Sunnen’s first generation of deep hole drilling machines. Servo-driven ballscrews for the tool feed provide more precise positioning and a longer service life than a rack and pinion system, while heavy-duty linear rails transport the tool driveshaft vibration dampers and tool drive spindle carriage.

The SHDD-4500 supports parts up to 13.12 feet (4 m) in length, with a maximum part outer diameter of 508 mm. For solid drilling, the machine supports inner diameters from 0.8–5.0 inches (19 to 127 mm), with counterboring and trepanning up to inner diameters of 7.0 inches (177.8 mm). But despite the wide range of potential sizes, Midwest has found that the machine holds close tolerances on hole size and drift. According to Huiras, hole sizes have held at ±0.005 inch (0.127 mm), with hole drift at less than 0.001 inch (0.0254 mm) per inch drilled.

This level of accuracy surpasses Midwest’s other deep hole drilling machines and enabled the shop to increase speeds and feeds 20-30% on alloy and stainless steel workpieces that go on the SHDD-4500. This increase in pace has helped Midwest keep its lead times down to a week and a half, even in the face of increased demand.

Related Content

Inverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreCustom Motorcycle Parts Made Here: Video Tour of a Family-Owned CNC Machine Shop

Lee Wimmer invited us to tour his second-generation family-owned machine shop in Perkasie, PA. This video explores the production processes behind precision-machined parts for both Wimmer Custom Cycle and LS Wimmer Machine Co., and shows how ingenuity and determination are still at the heart of American manufacturing. Today, both companies are now managed by Wimmer’s three sons.

Read MoreA History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read MoreRead Next

Answering 5 Honing FAQs

Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Here, a leading honing equipment manufacturer answers a few commonly asked questions about this process.

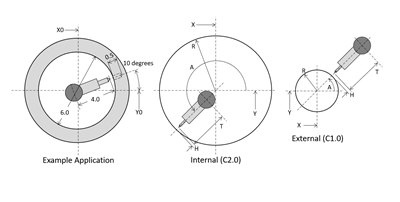

Read MoreHow to Drill Holes With a Right-Angle Head

Drilling with a right-angle head in a machining center spindle can be tricky – doubly so if the hole must be peck-drilled. A custom macro and careful attention to positioning help ensure smooth production.

Read MoreDeep-Hole Drilling Automation Is More Than Part Load/Unload

Automation inside deep-hole drilling machines can be more valuable than part handling outside of them.

Read More