Share

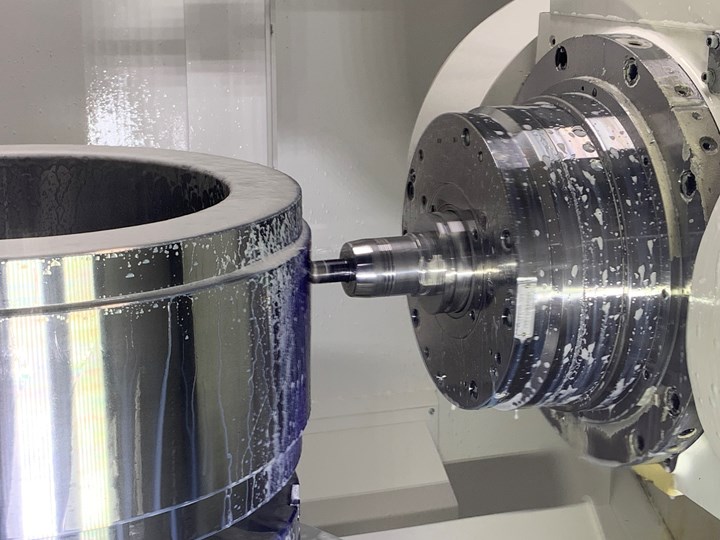

To speed up its briquette roll production process, Komarek purchased a Mazak Integrex i-630 turn-mill machine to pair with Ceratizit tooling and machine alloy, stainless and tool steels.

Photo Credit: All photos courtesy of Komarek

Briquettes are dense blocks created by compressing certain materials. For instance, charcoal and water softener salt are prepared as briquettes using charcoal dust and sodium chloride, respectively. These blocks can be compressed in cantilevered removable cutting rolls like those machined by K.R. Komarek, a Wood Dale, Illinois, company whose founder, Gustav Komarek, patented briquetting processes in the early 1900s to make coal less dusty and easier to transport.

With a wide variety of briquette designs, sizes and materials, machining these rolls is a demanding task for machine tools and, in particular, tooling. To overhaul a lengthy, hands-on process, Komarek paired a Mazak turn-mill machine with Ceratizit ISO-P-grade tooling to reduce production cycles and eliminate an arduous hand-grinding process.

A Historically Hands-on Process

In Komarek’s design, two rolls run in opposite directions while the material runs down the middle to be compacted. Materials for these cutting rolls – which measure from 12 inches up to 28 inches in diameter – range from stainless steels to alloy steels and tool steels with hardness from 25 to 40 RC.

Until recently, Komarek’s manufacturing process relied heavily on drilling and high-speed milling to rough each roll, turning the rolls in two operations on one machine, then moving the workpieces to a horizontal mill. The shop would then hand-grind its roll pockets and rely on lengthy hand-polishing operations to achieve the necessary surface finish.

This labor-intensive process made unattended operations impossible, which in turn meant that a single roll took three workdays to produce on a one-shift, eight-hour schedule. Even then, the manual operations made high-quality surface finishes and other specs more difficult to attain with high repeatability.

Modernizing Milling and More

Growing the company would require a smoother, more repeatable production cycle. Komarek decided to replicate its existing process as a milling operation with two setups. To achieve a surface finish of 16 Ra for all pockets, the company invested in a Mazak Integrex i-630 turn-mill machine with a two-pallet changer and modular automated pallet-stocking system. The machine incorporates an 800-mm pallet size, plus a tilting spindle and rotary table for simultaneous five-axis operations and multiple-surface machining of large, complex parts up to 28" in diameter and 27" high. With some rolls containing up to 50 pockets, a machine that could handle complex maneuvers while holding large parts was ideal for Komarek’s workload.

In addition to a versatile machine, Komarek needed durable tooling that could machine its complex roll pockets. Operations Manager David Rammacher came to Komarek from a position at Ceratizit, so he was already familiar with the company’s indexable carbide tooling. He believed that using a version of this tooling with round inserts could improve milling performance on the roll pockets.

Komarek now relies on some of Ceratizit’s ISO-P grades. These include HSK100 CNMG holders and CTCP135-P carbide turning tools for rough turning with interrupted cuts. For finish turning, HSK100 DNMG holders with CTCP115-P ISO-P15 wear-resistant grades provide optimal resistance to high temperatures for ideal tool life during steel machining at high speeds. Additionally, to handle milling chores, Komarek chose Ceratizit’s K2002 ball-nose indexable cutters in diameters ranging from 8 mm to 32 mm mounted in HSK100 hydraulic chucks.

Once Komarek added new equipment on its shop floor, the company called on Ceratizit to assist with tool-drawer setup for inventory management.

In addition to this new tooling arsenal, Komarek brought in Mastercam and began utilizing 3D tool paths after previously relying on 2D tool paths. Rammacher says the ability to utilize more complex tool paths in conjunction with new tooling helped achieve an improved surface finish, so much so that Komarek eliminated the need for hand grinding, the most labor-intensive process in the production cycle. At the same time, the palletization abilities of their new machining center enabled them to run lights out, which lengthened their production days without increasing demands on staffing. What once required three eight-hour workdays became a one-day job.

“We can save hours and even days just (eliminating) the pocket grinding,” says Rammacher. “And nowadays, finding somebody that’s willing to do that day after day, it’s increasingly tougher.”

Employees who formerly would have been tackling manual tasks on the briquetting roll production line can now work in Komarek's reconditioning and repair department. These new processes also eliminated the potential for human error from hand-ground pockets, and by previewing milling paths through simulation features within Mastercam, Komarek is seeing less than a thousandth of an inch of variance in pockets. Tool life has also become much more predictable.

“Now, we can predict tool life on each material," says Dan Diemer, CNC machinist at Komarek. "Our process improvements include huge gains in repeatability and reliability.”

The briquette rolls Komarek machines can have anywhere from 20 to 50 pockets depending on the material that is getting compacted and the machine the roll will be used in.

Rolling Out Orders

At any given time, Komarek has 40 orders in its shop for two-roll sets, of which it typically produces up to three each week, more than it was machining under the old processes.

“It wouldn’t have been three going from start to heat treat in a given week,” Rammacher says. “It would’ve been maybe two. It could even be less depending on the rolls.”

Not only do customers need replacement and spare cutting rolls, but briquette shapes change frequently and some jobs call for the addition of lettering or logos to the briquetting pockets. Some Komarek customers process steel, which requires a high roll hardness. Some operate on corrosives such as salt or cyanide, which can eat away at the roll material. As a result, the processed material itself, as well as the desired final shape of the briquettes, determines the specifications and size of each roll.

With new machining and tooling support, Komarek has cut its production steps, boosted its accuracy and repeatability, and increased overall efficiency throughout the shop. "What we've been doing is working. We're just trying to reduce costs and bring value to the customer," says Rammacher. After seeing the results of their new approach, Komarek ordered a second Integrex i-630 machining center to continue to optimize its production process.

Related Content

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)