CMMs Provide Reliable, Accurate Measurement Data

Having used a CMM from Carl Ziess for about a decade, this manufacturer turned to the metrology supplier again when it needed additional inspection capacity. The MMZ B and Accura CMMs delivered the accuracy and reliability the shop had come to expect.

Share

Autodesk, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Takumi USA

Featured Content

View MoreFor Gary West, sales and customer service manager at Indiana Technology and Manufacturing Companies (ITAMCO), few parts of the manufacturing process are as critical as the accuracy and reliability of the company’s measuring equipment. “You can talk all you want about making good parts, but the proof is really in the inspection report,” he says.

With that mindset, it seemed natural for the company to turn to an already trusted equipment supplier, Carl Zeiss (Maple Grove, Minnesota), when it sought additional CMMs for increased inspection capacity in 2007. The Accura and MMZ B CMMs delivered not only the quality data the company had come to expect from Zeiss equipment, but also the ability to output that data in various formats to ensure a comprehensive overview of inspected parts.

For more than 50 years, ITAMCO has produced primarily energy-industry parts, including components for coal mining, wind energy and oilfield equipment. The company has two business units: Indiana Tool–Indiana Gear, which provides precision machined components to OEMs, and ITAMCO Energy, which focuses on developing renewable energy projects and technologies. The company’s 100,000-square-foot facility in Plymouth, Indiana serves as its headquarters and is used to manufacture precision parts ranging to roughly 2 meters in size. In 2006, the company began production at an additional facility located about 10 minutes away from the headquarters in Argos, Indiana. Measuring 385,000 square feet, this plant machines parts ranging in size to about 4 meters.

At first, parts manufactured at the new Argos plant were either measured using portable-arm equipment or transported to the Plymouth headquarters for inspection on the Zeiss Mauser CMM there. However, this was only a temporary solution. Properly supporting production at the Argos plant would require a dedicated, stationary CMM in a temperature-controlled inspection lab. Moreover, the energy and commodity markets the shop serves were in the midst of an upswing at the time the shop brought the Argos facility online, leading to a substantial increase in business, Mr. West says. This necessitated additional inspection capacity at the Plymouth headquarters as well.

Thus, in mid 2007, the shop set out to purchase two new CMMs, one for each facility. “We’ve used the Mauser CMM at our Plymouth plant for about 10 years, and that machine has always provided excellent results and reliability. Considering the history we’ve had with it, it was an obvious choice to purchase the two additional CMMs we needed from Zeiss,” Mr. West says. In the end, the company decided on the gantry-type MMZ B model for the Argos facility and the bridge-type Accura model for the Plymouth facility.

The MMZ B features a low-tension, annealed, welded-steel construction that is said to increase thermal stability and reduce measuring uncertainty. Features include antifriction guideways on all axes, interlocking ballscrew drives and covers on all horizontal guideways to prevent dirt deposits and other contaminants. ITAMCO uses the machine to measure primarily ring gears and other components of mining truck wheels, as well as wind energy parts such as 7,000-pound housing for a 1.5-megawatt gearbox and a rotor hub for a 750-kilowatt turbine. Depending on part geometry, it typically measures six to 12 components per day. Mr. West says the CMM is ideal for meeting the tight tolerance requirements of the larger-diameter parts manufactured at the Argos plant.

The Accura features a granite machine table; a lightweight bridge for high flexural strength; thermally neutral, ceramic/glass scales; and four-sided air bearings for stability and precision. Although the machine is capable of both optical and contact scanning, the shop predominantly uses the latter inspection method, Mr. West says. The Plymouth facility uses the machine to measure relatively small parts, including top-drive components for oilfield applications and spindles for mining trucks. “The Accura is user friendly and gives us good data in a very short amount of time,” he notes.

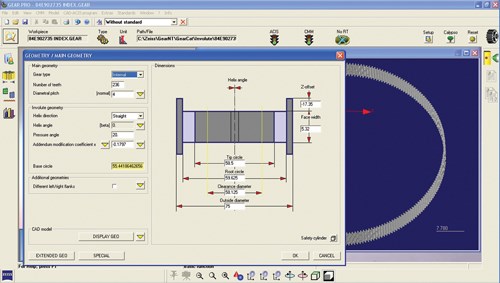

Both machines are equipped with Zeiss’ Calypso and Gear Pro software packages. ITAMCO’s Chip Mersch, who operates the MMZ, says Gear Pro is easy enough to use that he was able to run it after a single afternoon of training. He cites the software’s greatest benefits as the variety of tolerance classes and gear specifications from which to choose, multiple output options that enable a better picture of measurement results and measurement simulation capability that helps ensure the program will run correctly.

With customer requirements ranging “all over the board,” the ability to select a number of different American Gear Manufacturers Association (AGMA) classes is especially useful, Mr. West adds. He explains that these classes specify different requirements for profile error, lead error, tooth spacing, runout and other features, depending on the gear’s size and tooth configuration. Additionally, the ability to output measurement results in various scales makes it easier to see variations in measurement readings and provides a more comprehensive view of the data.

Related Content

Help Operators Understand Sizing Adjustments

Even when CNCs are equipped with automatic post-process gaging systems, there are always a few important adjustments that must be done manually. Don’t take operators understanding these adjustments for granted.

Read MoreChoosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

Read MoreHow to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)