Most people probably don’t give much thought to how prepackaged food products arrive on grocery store shelves fresh and undamaged. Employees at Freeman Company, however, have a better idea about what goes on behind the scenes to ensure the rest of us can enjoy this modern convenience. Plastic food packaging comes in a variety of shapes, each of which requires specialized metal tooling to form. Producing this tooling is Freeman’s specialty.

In addition to the complexity of many of these tools, the Freeman team must contend with tight production schedules. In fact, they are often required to take complete turnkey packages from design concept to final product in as little as 8 to 10 weeks. To meet these demands, the company relies heavily on an automated, two-machine cell driven by a controller from Erowa (Arlington Heights, Illinois). Since installing the cell, the company has significantly improved job scheduling flexibility and increased both unattended production hours and spindle utilization rates, says Larry Mears, president at Freeman Company.

The tooling produced at Freeman’s manufacturing facility in Fremont, Ohio is used in a process called thermoforming. Each tool features cavities that match the desired shape of the product—in Freeman’s case, this might be a mold of a takeout food container, a foam plate or a sandwich package. A continuous sheet of plastic is then fed or extruded over the mold cavities, typically from a roll that is slightly wider than the tool itself. The plastic is heated until pliable and then blown into the mold cavities with pressurized air. A vacuum system removes any trapped air and sucks the plastic sheet tightly against the mold’s contours. Finally, the formed sheet is cooled, removed from the mold and sent to a trim press that separates the finished product.

Freeman offers engineered or build-to-print solutions in configurations to fit all major thermoforming equipment, along with optional quick-change cavities and plugs to minimize change-over times between jobs. Many tools involve complicated shapes and deep cavities. Work ranges from prototypes to high-volume tools used to produce hundreds of plastic parts per cycle, a rate that translates to thousands of pieces per hour.

The company endeavors to stay up-to-date on the latest technology, as evidenced by some of its more recent equipment acquisitions. Over the past few years, it has added two lathes, a wire EDM and two milling machines to the array of equipment on the shop floor. One of the most significant of these investments was in October 2009, when the company made its first foray into five-axis machining with two Mikron HSM machining centers from GF AgieCharmilles.

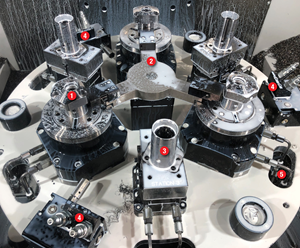

The company purchased the machines with automation in mind, and within the next few months, it installed a 40-pallet magazine as well as a robotic work delivery system and cell controller, both from Erowa. The robot automated loading and unloading, and operators soon found themselves spending most of their time at the cell controller rather than interfacing with the individual machine CNCs. It wasn’t long before the machines were running either lightly attended or completely unattended 24/7.

Today, the company frequently achieves spindle utilization rates as high as 90 percent, Mr. Mears says. Throughput and lead time on cavities have significantly improved. Additionally, the cell provides the flexibility to insert rush jobs or one-piece prototypes in the middle of production runs without disrupting the production schedule. This flexibility and efficient use of time and resources is attributable in large part to the “brains” of the cell, the Erowa EMC manufacturing control software, says Michael Mullholand, COO. “The queuing system can send work to the first available machine or to a dedicated machine,” he explains. “We can have a mix of low- and high-volume work running at the same time, or break into a production run to get out a quick prototype or repair part. The Erowa management software will even send an email or a text message if there’s a problem such as a broken tool or if a machine is out of work.”

More flexible job scheduling makes the company’s substantial equipment investment more justifiable. That is especially important for Freeman, which strives to use as much of the capability of its machines and other equipment as possible. “If you’re going to buy a Ferrari, you have to drive it like a Ferrari and not like a tractor. Otherwise you just spent a lot of money for nothing,” Mr. Mears explains. “The automation provided by the Erowa system allows us to get more bang for the buck on a machine tool purchase.”

The machining centers themselves feature spindle speeds of 36,000 rpm, rapid traverse rates of 1,653 ipm, tool magazines with capacity for 170 tools and Heidenhain iTNC 530

controls. Using Erowa fixtures exclusively in the cell makes it easy to accurately transfer workpieces between the machines, Mr. Mears says. The Erowa Robot Linear that services them can work with as many as eight machine tools and 1,000 pallet positions, leaving plenty of room to expand the cell as needed.

In fact, that expansion might become a reality. The improvements realized so far have prompted the company to consider adding more machines to the cell in the near future, Mr. Mears says. Integrating any new equipment with the Erowa systems should be relatively seamless because the management system and robot can accommodate any other types or makes of machinery. “We can plug in any machine tool as long as it has an automation interface,” he notes.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)