Bio-Based Machining Fluids Improve Efficiency and Tool Life

New bio-based machining fluid formulations improve tool life and productivity without troublesome films and foams.

Share

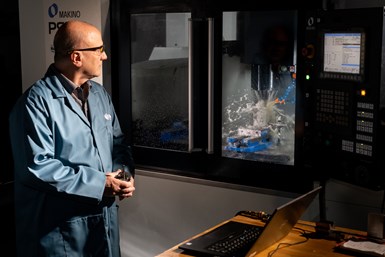

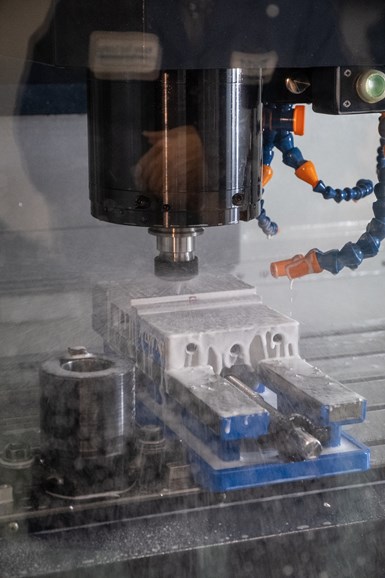

Preliminary case studies for MFS’ USDA BioPreferred TRIM HyperSol 888NXT suggest that modern bio-based cutting fluids are not only beneficial for the environment, but for users’ pocketbooks as well. The coolant doubled one customer’s productivity and led to widespread tool life increases and usage improvements. Images courtesy of Master Fluid Solutions.

If Master Fluids Solutions’ (MFS) latest synthetic fluids are any indication, the next generation of bio-based coolants could surpass traditional coolants in both environmental and economic performance. As Inconel, titanium and heat-resistant superalloys deliver some of the lowest tool life and productivity of machining applications, MFS focuses its bio-based coolant development on applications with these materials — and MFS’ business development manager, Justin Geach, describes the latest generation’s test results as “almost too good to be true.”

Case studies with MFS’ TRIM HyperSol 888NXT bio-based coolant show these massive improvements carry through to real-world applications. A manufacturer of impellers for automotive turbochargers and aerospace turbojet engines replaced the conventional coolant for its automated five-axis titanium machining with MFS’ bio-based coolant and increased tool life by 22% while reducing coolant concentrate usage by 50%. Another aerospace parts manufacturer machining 35NCD16 steel alloy achieved higher speeds, lower coolant makeup concentrations and a 234% tool life increase on its CNC lathes. A jet engine and high-speed airframe component manufacturer in California tripled tool life and cut coolant concentration from 35% to 15% when grooving in Inconel 718. Topping it all off, a precision machining manufacturer working with 17-4 stainless steel more than doubled its productivity, from between 16 and 18 parts per hour to between 36 and 40 parts per hour.

What Are Bio-Based Coolants?

The precise boundary between synthetic-based fluids (a category which includes bio-based coolants) and petrochemical-based ones is not always clear — a fully synthetic fluid may not include mineral oils, but may still contain ingredients that are petrochemical-based. For their part, Geach and MFS define bio-based fluids as those “where the majority of the components in that formula are based on renewable or bio resources. For example, our TRIM HyperSol 888NXT is made of 54% renewable resources.” Besides coolants, other candidates for bio-based fluids include straight cutting oils and forming, drawing and stamping compounds.

Reduced tool usage and consumption have knock-on effects for other stages in the machining process, such as machine cleanouts and waste hauling, and as such greatly impact emissions.

Whereas conventional coolants have historically forced users to choose between lubricity or cooling, bio-based coolants can provide both simultaneously, Geach says. Despite this flexibility, bio-based coolants have historically seen limited use due to their tendency to form residues and foams, as well as their shortened sump life. Newer formulations like MFS’ TRIM HyperSol 888NXT reduce and can even eliminate these issues.

Process efficiency can make a larger impact on the carbon footprint of machining fluids than actual oil content — thankfully, recent advancements in bio-based machining fluid formulation mean these fluids not only have lower oil content, but they also perform better for difficult applications.

Economic and Environmental Improvements

The environmental impacts of bio-based machining fluids extend beyond lower carbon in the fluid itself. Reductions in tool usage and coolant consumption like those achieved by the customers mentioned above have knock-on effects for other stages in the machining process, like machine cleanouts and waste hauling, and as such, usage improvements impact emissions even more than first appearances suggest. Lower oil percentages are an environmentally friendly bonus of these fluids rather than the primary benefit.

The environmental impact of synthetic straight cutting oils like MFS’ ester-based cutting oils also extends beyond the fluids themselves. These oils achieve higher lubricity with lower viscosity, and that lower viscosity improves recyclability through lower chip carry off and drag out. Users need less of the fluids for the same jobs, lowering costs and carbon emissions.

Related Content

Managing Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Read MoreSTLE Opens Registration for 2024 Annual Meeting

The Society of Tribologists and Lubrication Engineers’ 2024 STLE Annual Meeting & Exhibition will take place May 19-23 at the Minneapolis Convention Center in Minneapolis, Minnesota.

Read MoreRego-Fix Toolholding System Reduces Coolant Consumption

MQL PG collets are designed for machines using one-channel, internal through-spindle MQL systems.

Read MoreMaster Fluid Solutions Semisynthetic Coolant Inhibits Corrosion

Trim MicroSol 685XT is designed to provide enhanced corrosion inhibition on all ferrous and nonferrous metals.

Read MoreRead Next

Can Nanotechnology Redefine Metalworking Fluid?

Tiny onions provide a maintenance-reducing alternative to hazardous chemicals for cooling and lubricating parts.

Read MoreCoolant Recycling System Improves Tool Life, Reduces Costs

This Canadian aerospace manufacturer cut coolant costs by 75 percent by installing a PRAB Guardian coolant recycling system, eliminating terrible smells in the process.

Read MoreSynthetic Cutting Fluid Keeps Shop Cleaner without Sacrificing Performance

Sometimes synthetic metalworking fluids end up negatively impacting tool life when used with tough materials. Wells Manufacturing overcame that issue when it converted to a new product from Blaser Swisslube.

Read More