Active Scanning Collects Complete Bore ID Form Data

Complete form measurement data on complex bore interiors helps this specialist in precision tubular components hollow out an even more competitive niche.

Share

A bird’s-eye view from a high balcony is the closest look most visitors ever get at Tube Hollows International’s 20,000-square-foot main production area, and that’s for good reason. The 27 gundrills turning exotic-material bar into highly concentric, uniform-walled tubing, often with extreme length-to-diameter ratios, aren’t standard models that anyone can purchase. They’re the company’s own design. That’s not to suggest that these are “magic machines,” says Dave Morse, general manager, explaining that what the company is really trying to protect is the proprietary process that created the need for this customized machinery in the first place.

“For us, everything starts at the center,” he says about the 50-employee company’s “borecentric” approach to drilling. Leveraging this technique, machinists at this specialist manufacturer in Windham, Maine, can locate a tube’s inner diameter (ID) in relation to its outer diameter (OD). That’s a stark contrast from the common approach of drilling a straight hole, centering on the ID and then turning down the OD, Mr. Morse explains. In addition to facilitating total indicator runout (TIR) of 0.008 inch or less on stock as long as 25 feet, borecentric provides savings on costly materials like titanium and nickel-based alloys, and it enables drilling or reconditioning shafts with pre-machined OD features.

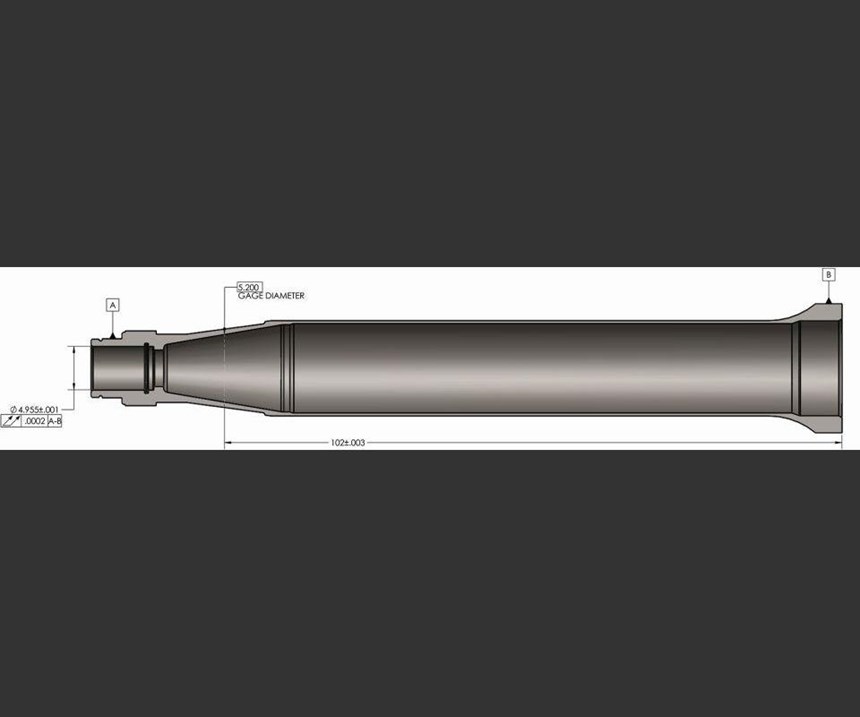

Nonetheless, he insists that the company could never realize the full competitive potential of borecentric drilling without advancing its metrology capabilities to a similar level as its machining capabilities. Andrew March, technical sales engineer, says bore gages and other handheld instruments simply aren’t sophisticated enough to service Tube Hollows’ newest customers: aerospace and energy industry manufacturers that demand more than just straight, uniform-walled tube. Scanning on a coordinate measuring machine (CMM) has proven essential to providing complete geometric dimensioning and tolerancing (GD&T) form data for the complex, feature-rich interiors of tubular parts like turbine actuators and landing gear components.

However, not just any scanning head would do for the company’s new Contura G2 CMM, purchased from ZEISS Industrial Metrology this past June. Measuring recessed slots and notches; protruding geometry like ribs and splines; multiple, contouring diameters with stepped-radii transitions; blind bore bottoms that are perfectly flat; and other complex features deep inside of tubes typically requires long stylus extensions. Too long, in fact, to measure reliably, or sometimes even at all, with a passive scanning head and its static system of springs and displacement sensors. Instead, the company chose the Vast XT Gold, an active scanning head that leverages force generators and other internal components to maintain an even, user-specified level of force on the part surface. In the process, it compensates for any extra force created by long or heavy styli, says Kevin Donovan, senior technical sales engineer at Zeiss.

Given the added complexity, active scanning of in-process parts also plays a critical role in keeping production of these tubular components on track. Finally, it helps slake newer customers’ thirst for comprehensive form data, including for OD geometry and even parts that aren’t tubular at all. “The more complex the feature, the greater the benefits of active scanning,” Mr. March says.

Metrology Catches Up

Along with earning the necessary credentials (Tube Hollows received AS9100 certification this past February), Mr. Morse says he and the rest of the leadership have viewed the addition of a CMM as a key step toward reaching the next phase of the company’s development since its founding.

Getting there didn’t take long. The company was founded in 2011 by a small team from a larger manufacturer that had been acquired. Armed with a small stable of essential hole-making equipment that had been left out of the acquisition, Tube Hollows International moved from a smaller leased space to its current, 50,000-square-foot facility within one year. Mr. Morse credits steady growth since then to the company’s singular focus on its core niche, particularly its reputation for medical industry parts like titanium intramedullary rods and nitinol tubing.

Nonetheless, focusing only on concentric, uniform-walled tubular components would leave out the aforementioned aerospace and energy work, which Mr. Morse and the rest of the leadership consider essential for future growth. Although more challenging—typical lead times range from 8 to 12 weeks, as opposed to 2 to 4 weeks for legacy jobs—these parts have proven to be well within Tube Hollows’ machining capabilities, Mr. March says. However, measuring ID and OD sizes, TIR and surface finish isn’t enough for customers that require fully defining complex-geometry ID forms. Unlike a handheld measuring instrument that would require projecting profile geometry based on a few select measurements, CMM scanning paints 3D contours in thousands of data points that can be interpreted directly. Form callouts like cylindricity, a combination of roundness, straightness and taper measurements, are also easier and more precise.

Still, even those inspections that could be relegated to hand gages are often conducted on the CMM instead. Concurrent engineering is the norm at Tube Hollows, and manufacturing often begins prior to determining precisely what measurements will be most useful for defining the part geometry in the future, Mr. March says. Leveraging the unit’s Calypso software, the company and its customers can apply various algorithms to interpret the same data in different ways. “Once we’ve established a baseline, we might want to look at form from part to part to make things more uniform, or maybe break down the data further or according to different criteria,” he explains.

Precision Becomes an Active Pursuit

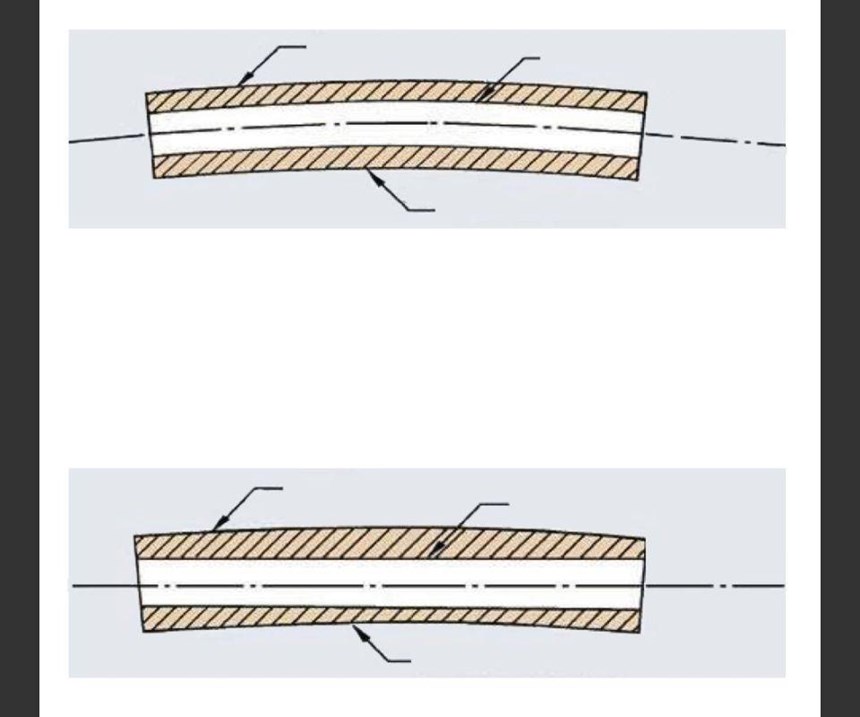

Software capabilities aside, none of this would be possible had the shop opted for a passive head with the new CMM. Passive units collect surface data via internal gages that measure the extent to which springs connected to the stylus compress and relax as the probe deflects off the part surface. Mr. March likens this construction to a common amusement park ride: antique automobile replicas that can turn only so far before contacting a guide rail that lines the center of the track to prevent vehicles from steering off course. Similarly, the accurate operating window of a passive head is dictated by how far the springs can stretch or compress without compromising measurement results. Although typically imperceptible to the human eye, sagging caused by the force of gravity on a longer stylus can partially or even fully close this window before an inspection routine begins.

With capability to adjust in real time to control probing force, an active scanning head suffers no such restrictions. Along with a series of parallelograms that actively stabilize the styli, internal force controllers, sensors and scales ensure that the Vast XT Gold applies the same, even level of probe pressure on the surface regardless of gravity, approach angle, part geometry or any other external factor, Mr. Donovan says. As a result, the probe can accommodate styli as long as 500 mm and as heavy as 500 g.

An active scanning head’s complex internals preclude the use of the articulating holders that are commonly used with passive models. As a result, a complex ID might require multiple stylus extensions, with various combinations of connections and angles that ensure the probe approaches at a normal (perpendicular) vector to measured surfaces. At Tube Hollows, these extensions are typically assembled from Zeiss’s ThermoFit Pro system. As opposed to the more common aluminum or titanium, these units’ carbon fiber construction is designed to provide a combination of stiffness, light weight and thermal stability that Mr. Donovan says is particularly critical in long-reach applications. As for the probes themselves, Tube Hollows tends to favor silicone nitride tips over the more common ruby ones, which wear too fast in Hastelloy, molybdenum and other hard materials, Mr. March says.

Gage repeatability and reproducibility (R&R) studies are critical to minimizing measurement uncertainty with these long styli, Mr. March adds. As for process planning, Calypso software’s Navigator wizard helps greatly in zeroing in on the proper application parameters, he says. With stylus systems configured and programming complete, operators qualify the probe by scanning the same portions of the reference sphere at different force levels. Known as tensor qualification, this procedure determines precisely how much the stylus will bend per unit of force. Guided by the program, the CNC and sensor feedback, the internals of the head do the rest.

Tube Hollows’ metrology procedures can be considered “active” in a broader sense than the company’s choice of scanning technology. The CMM sees a great deal of activity from job to job because production of newer, more complex parts is a constant relay between the quality control area and shop floor, where active scanning data guides every phase of the process. As an example, sales manager Evan Spoerl cites a recent job that involved precisely locating a critical radius at the transition between two ID diameters in relation to a particular point on the OD. In this particular case, pulling the part for offline inspection verified that the boring bar had reached the proper depth. However, such scans often reveal the need for slight process adjustments.

So the process goes, step by step and often amid ongoing back and forth with the customer, until the time comes to prepare a full inspection report. At that point, the lion’s share of necessary data has already been collected, Mr. March says. This saves some measure of time, but it hardly makes up for the fact that in-process inspections require additional setups away from the shop floor between operations. Even so, the disruption is minimal because complex, hard-material parts take a long time to machine, Mr. March says, citing cycle times measured in hours for certain drilling and boring operations. In a way, this is a luxury, because it leaves ample time to plan and conduct scans that generally take about 20 minutes apiece.

This isn’t to suggest that Tube Hollows doesn’t prioritize machining efficiency, Mr. March says. On the contrary, this is always a goal (recently, the company invested in a machine that combines turning and milling functionality). Rather, it reflects the nature of the work. It also reflects the fact that in-process CMM scanning has become a necessity, both for manufacturing parts in the first place and for providing the comprehensive form data that facilitates critical engineering discussions with customers (hence the willingness to perform even simpler measurements on the CMM). In short, customers turn to Tube Hollows not for quick-turnaround work, but to solve challenging design problems and to ensure high precision on mission-critical components that can often put lives at stake when they fail.

Beyond Tube Hollows

Long reaches aren’t the only reason why the team at Tube Hollows considers active CMM scanning to be a critical capability. Force control also facilitates measurements on surfaces with mirror-smooth finish callouts (some parts have required 63 Ra) or precisely honed patterns. Even for a simple measurement, a light touch with a ruby-tipped probe is far preferable to the steel pins of a bore gage on such surfaces, Mr. March says. “We can actually measure expanded polystyrene foam (Styrofoam) with it,” Mr. Donovan adds about Zeiss’s own trials with the Vast XT Gold.

In fact, active CMM scanning is proving beneficial for parts that aren’t tube-shaped at all, but merely complementary, such as a gear that’s part of the same assembly. Tube Hollows sees this typically complex work as an additional opportunity to double down on its core niche, this time by providing a broader service offering. Although a passive head could offer advantages of its own on jobs that don’t require long reaches, the company isn’t considering investing in that technology any time soon. The complete picture painted by active scanning data is too important, Mr. March says.

All things equal, long reach or not, active heads generally provide more data than passive models, Mr. Donovan says. With constant, real-time adjustments during scanning, an active head can be thought of essentially as a mini CMM in and of itself, one located much nearer to the point of measurement, he explains. This adds a level of finesse to the proceedings beyond the axis motors driving the mass of the broader machine. In contrast, a passive head is just that. With no active force control or stabilization, pressure changes with every contour as the deflecting stylus drags the probe across the part surface. As a result, passive systems must rely more on compensating software algorithms to accomplish the same ends.

Mr. Donovan emphasizes that these algorithms are extremely sophisticated, and that Zeiss quotes the same measurement uncertainty for both scanning head varieties. Nonetheless, in industrial production conditions (that is, outside a quality lab environment), “the active scanning head may be able to cope with less-than-ideal part to part variations better,” he says.

That’s just the kind of thing that concerns Tube Hollows’ customers. “The more complex the feature, the more types of algorithms we may want to apply to it,” Mr. March says. Describing the advantage of active scanning for that end, he returns to the analogy of the amusement park antique cars with motion limited to a certain, narrow path. “If you’re driving an active probe up a gear tooth, it’s going to follow that contour and maintain a certain amount of pressure wherever the contour takes it,” he says. “A passive probe is driven by a nominal, and if the nominal and the actual start to deviate, the results are going to deviate, too. For us, active scanning was an easy decision.”

Related Content

4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

Read MoreHow to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreHow to Choose the Correct Fixed-Body Plug Gaging Solution

The two types of fixed-body plug gages are both accurate, fast and easy to use. Consider these factors when selecting one for your gaging application.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More