A Place in Manufacturing Should Be Earned, Not Given

How do your children fit into your succession plan?

Share

As a parent, I would love nothing more than to share the legacy of manufacturing with my children and their children. At a young age, my start in the industry arose from no such sentiment. My parents weren’t necessarily looking for a succession plan; they were looking to fill a labor gap. At the time, it was not unusual to look to one’s own family to accomplish that, and my parents were no exception. However, they also made it clear that being family meant being held to the highest standards.

This is not a criticism. Taking it easy on us would have been a gross disservice. Holding us to high standards of performance—higher even than any of their later hired help—was their way of protecting our future selves from exploitation. I have no regrets about my early years, and I know my parents don’t either.

Counting my two brothers, it was just the five of us in those early days. We did it all: cleaning out oil, grinding, answering phones, whatever it took to run our centerless grinding shop. On our commute, we would look for flatbed trucks loaded with barstock and write down the business names so we could find them in a phone book and cold-call them. Though we went to school and dabbled in a social life, my brothers and I would often look for ways to get back into the shop.

With many of today’s successful manufacturing businesses already being well established, less of our children spend the majority of their free hours in the shop. This is probably a sign of progress, one in which they can pursue academic interests and explore other careers. As much as it opens them to new experiences, it can also pull them away from the industry, sometimes permanently. In such cases, our course for finding a successor is clear: hire one.

Yet, when our children delay showing a sustained interest in our business until later in life—perhaps even in their late teens or 20s—questions arise. How hard do I push them to follow in my footsteps? Do I want them to sacrifice work/life balance and weekends? Do they? And if they do want it, can I trust them to safeguard the livelihood of my employees and their families? Will they factor that livelihood into every decision they make?

As it turns out, the answers to those questions lie in what I learned while working for my family. By this, I don’t necessarily mean how to operate the machines, spot defects or keep a clean and organized shop. The most crucial lesson was “amanah,” and in Arabic it means respect, trust, accountability and responsibility.

When I was young, it meant proving to my parents and peers that I could contribute. Now, it weighs heavier because I owe it to my team to find those same things in my successor. The potential critical point of failure is clinging to the belief that our children are the only viable succession options. If I were to look elsewhere, I would read the applicant’s resume, investigate their reputation and examine their accomplishments. However, with children, we can mentor them and witness their growth. It is a tremendous challenge, but also a welcome opportunity.

Respect starts by demonstrating a willingness to learn from others. Few in the shop want to take orders from someone that has not mastered the fundamentals of manufacturing. If our children can accept instruction, then they are also learning how to follow—a lesson they must learn in order to lead effectively.

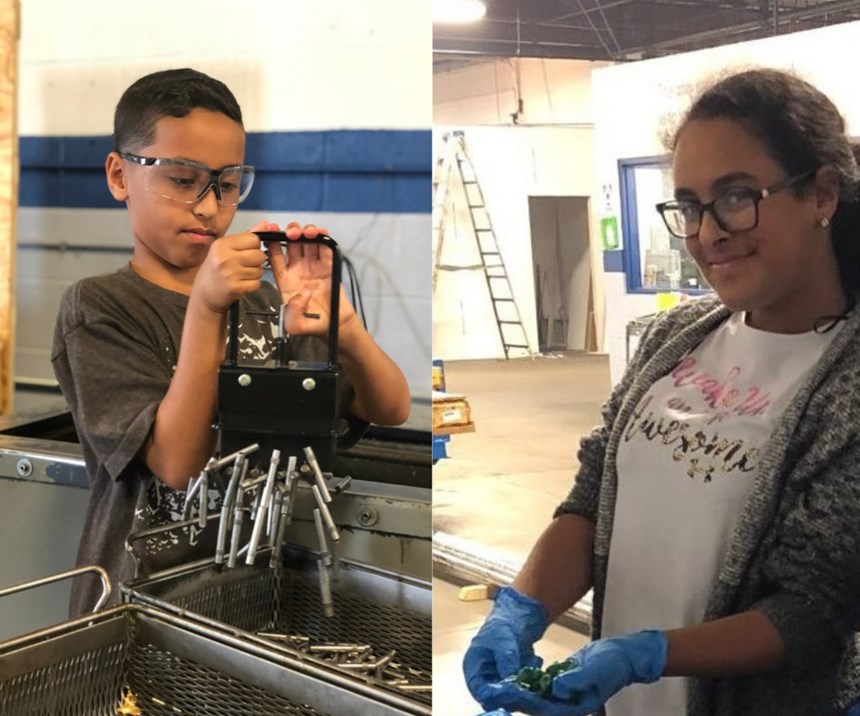

In addition, getting their hands dirty enables them to prove their commitment while simultaneously keeping their ego in check. Few things toxify a work environment more quickly than arrogance. If they are not willing to roll up their sleeves, put in long hours and take orders, how can they motivate their team to do the same? It is not necessary to make them scrub dumpsters, but I would never ask my team to follow someone unwilling to do time in the front lines and learn the standard of workmanship, even if it is just sorting parts.

When our children make mistakes, give them the gift of accountability. When they mess up, the team will notice. Ignoring it deprives them of a learning opportunity and poisons the team with favoritism. Being willing to accept blame and learn from it speaks volume about character and leadership, and it makes our children more likely to share credit for their successes.

In the end, we can only be effective leaders if we love what we do. The absence of such devotion to manufacturing is not a crime, nor is a desire to pursue a career outside of the industry. Not everyone wants to get their hands dirty or even lead a team. Pushing them into unwanted roles can harm our businesses and, most importantly, ruin relationships with our children.

Once again, as a parent, I have a natural desire to share my legacy with my offspring. Finding answers to the above questions means finding balance between protecting my legacy and securing the future for my employees. Thankfully, respect, trust, accountability and responsibility can be taught. If our children are willing and able students, then they have earned that which cannot be given.

Related Content

Solve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreFinding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)