7 Impressions of IMTS 2018

The up-and-coming technologies hinted at during previous shows have now arrived, and they are being accepted as part of the now-standard means of making parts.

Share

The International Manufacturing Technology Show (IMTS) offers a showcase for disruptive technology, but this year’s IMTS faced disruptions of a different sort. Indeed, this was the most harried and challenged installment of the biennial show I can recall. The approach of a hurricane compelled many from the Carolinas to leave the show early or not come at all. In Chicago where the show takes place, hotel employees on strike chanted and beat percussion instruments in front of major downtown hotels throughout the entire week. There were also the small challenges adding to the flavor of this year’s show. One was the failure to find graceful accord between cab lines and the positioning of rideshare stations, resulting in a confusion that prompted drivers to encourage attendees to find them at a nearby hotel instead. And inside the convention center, the debut of a new format for booth numbers required long-time attendees to recalibrate their navigation of the show (though not a difficult recalibration, as it turned out).

Yet if any of the challenges had any effect on the success of the show, you wouldn’t know it from the numbers. The largest manufacturing event in North America had its largest year yet—another point that, like all the points above, I do not need to tell you if you were there. The record attendance is the reason you often had such difficulty making your way down the show aisles.

The technology exhibited this year significantly matured. Specifically, it matured in the way it was represented and in the way exhibitors and attendees understood it. The same currents we have seen gathering strength at previous shows—additive, automation, data, the embrace of higher-end machine tools—now showed that strength this year. Technologies that once seemed novel are now necessary; possibilities that once seemed promising are delivering on that promise.

Here is some of what I found at the show this year:

1. Record-Breaking Attendance and Exhibit Space

The final tally of 129,415 registrations broke the previous record (1998) by more than 6 percent. The over 1,424,000 square feet of exhibit space for 2,563 exhibiting companies also broke a record, making IMTS 2018 the first show since McCormick Place’s most recent expansion to occupy all the exhibit space this venue provides. To put it mildly, the show was busy.

Moreover, it was busy with visitors driven by serious agendas. The previous attendance record was 20 years ago. Back then, manufacturing facilities had more employees per machine, and there was a tradition of bringing large teams to the show. Today, leaner manufacturing facilities have to be more deliberate about who they send and why they send them. To a greater extent than in the historical past, attendees at IMTS are there with a focused mission.

“This is high tide,” said one long-time veteran of the machine tool industry. “You don’t often see an IMTS like this.”

2. Additive Manufacturing’s Sizable Presence

Additive manufacturing (AM) had a small pavilion in 2016, but this year’s pavilion was large enough that it took a determined stroll to traverse from one side to the other. The number of exhibitors in this pavilion tripled from the previous show, with plenty of AM companies and exhibits also spilling over into other booths and pavilions. The large presence for additive and the home it has found at this show demonstrated the widespread acceptance of industrial 3D printing as an option for making parts and tools, and it demonstrated the evolution of IMTS well beyond being a machine tool show.

This year, the additive pavilion was relocated to the West Building, a move that might have seemed like a downgrade until it was revealed how beneficial this change was. The pavilion’s previous position in the North Building near major machine tool builders drew in many attendees who were merely curious. The position in the West Building acted as a filter, because attendees had to be intentional enough to cross a street or causeway in order to see additive technology. Heavy traffic in this pavilion indicated that many were this intentional. A representative of one large, multi-site contract manufacturer said his company had sent a team to IMTS with a primary focus on additive. It was unclear whether this team would make it over the bridge to see machine tools. For all of this, though, the Additive Manufacturing Pavilion accounted for only 1 or 2 percent of the show, by space or by number of companies. We will see an even bigger AM Pavilion in two years.

3. Data as the Next Step for Hardware Performance

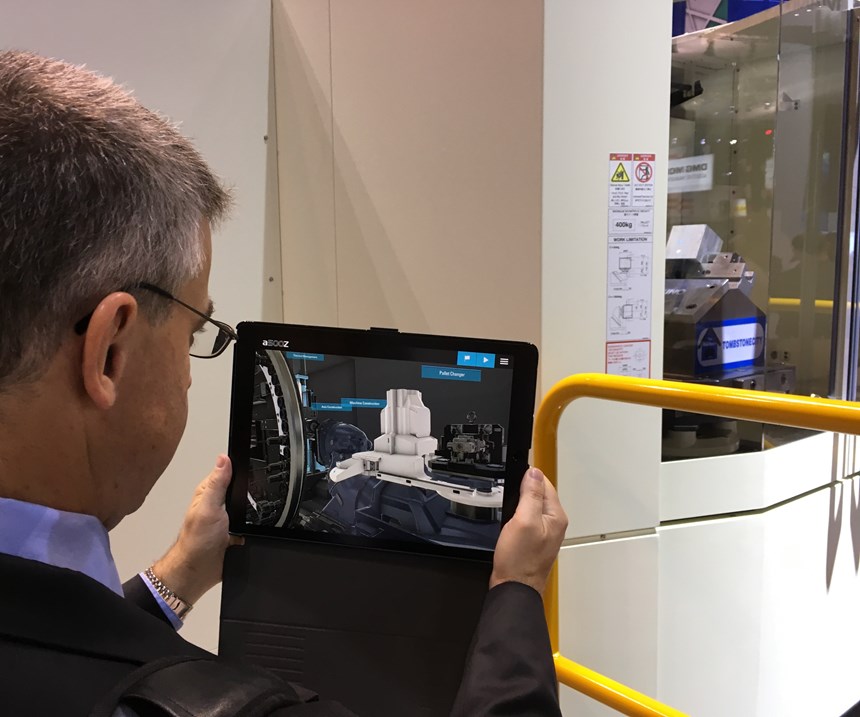

Major machine tool makers and even some tooling companies wished for attendees to see not just their hardware but also their analysis capabilities, and the chance for increased performance available to users willing to allow data about their use of the hardware to flow into analytical tools in the cloud. Mark Albert, MMS editorial director, described the development this way: “Everyone’s a software company now.”

Exhibitor personnel describing this data-analytics capability generally reached for the term “Industry 4.0” as an umbrella or category for what they are doing. They also frequently grimaced or rolled their eyes as they said it. “Industry 4.0” refers to a broad set of possibilities for digital manufacturing, with many of those possibilities still visionary and remote. By contrast, data analysis and data-driven refinement of machining and other part-making processes is on its way to becoming a practical, accepted, nuts-and-bolts part of manufacturing. We need another term for this transition, and we will need it in time for the next show, when we are likely to see greater capabilities for efficiency improvement tailored to individual manufacturing sites as a result of the analysis of those sites’ big data.

4. Automation as a Matter of Course

One major machine tool supplier well-known for integrating robots and other automation with machine tools did not have to imagine elaborate automated systems to show off as examples to exhibit at the show. Instead, every demonstration in the booth was a system currently in development to fill an order from a customer. A machine tool supplier at the front of the hall did not bother to demonstrate much at all in the way of automated systems (or even to show very many machine tools) because of the sense that the demonstrations at this point just get in the way. The options in robots, pallet systems and in-process automation are so numerous that the better display for this booth was a large graphical interactive touchscreen enabling visitors to dial in on the automated configuration possibilities best suited to their needs. Today, in other words, automation is a given. Robots are no longer an exciting draw to a booth exhibit because plenty of attendees see robots in their facilities every day.

5. Tooling and Accessories Revealing Machine Acceptance

The application of Swiss-type CNC lathes has expanded beyond its well-known applications, such as bone screws, with this machining capability now meeting needs such as the miniaturization of valve and control-system components. Cutting tool companies emphasized innovations in tiny, precise tooling in response to the expansion they are seeing of Swiss-type machining beyond specialty Swiss-type shops.

Meanwhile, exhibitors offering workholding for five-axis machining drew steady attention, their booth staffs often breathless from one encounter after the next in rapid succession. Five-axis machining has expanded well beyond specialists or niches as well, with the capability now used as as aid to setup reduction and therefore labor reduction in practically every industry in which simpler machine tools have long been used.

6. Hands Across the Concourse

Here is an observation that initially struck me as an odd surprise, but it has come to seem less frivolous the more I think about it: At IMTS this year, I saw couples walking through the show holding hands. I saw this plenty of times. I was not keeping count because it took me a long time to recognize this as noteworthy, but at a conservative guess I am confident I spotted this 15 times. In most of the previous versions of IMTS I have attended, I am confident I saw this once or not at all.

The crowds encouraged it. When being jostled by a lot of people, hand-holding keeps a couple in step. But the interesting thing is the presence of these couples. The demographic profile of IMTS attendees has changed. There has been a visible increase in attendees under 35—plenty of young faces (relative to mine) could be seen. In addition, there were more female attendees. Most attendees are still male, but women conversing with exhibitors or moving through the exhibits with focused attention were plentiful enough to be spotted with ease. And some women were there in close partnership with a man who was also there.

Indeed, some of the attendees I noticed in this way reveal that we are in danger of allowing our empowering images of women in manufacturing to become narrow clichés. Think “women in manufacturing careers,” and you might imagine a Rosie-the-Riveter-style machinist or a smartly dressed engineer—but in either case, a woman standing independent. Yet in many manufacturing businesses, a woman in manufacturing will be interdependent instead. That is, in many cases, she will be a spouse in manufacturing—a peer and a co-participant in a shared manufacturing enterprise. A woman in manufacturing will sometimes walk hand-in-hand (literally and figuratively) with a man in manufacturing.

7. 90 Years in One Exhibit

One final noteworthy sight at IMTS was one I am proud to say my own employer had on display. To celebrate the 90-year anniversary of Modern Machine Shop magazine, publisher Gardner Business Media displayed every cover of the magazine from the very beginning. Company Creative Director Jeff Norgord designed and helped build this unique display. Attendees slowly walked along the display to pick out covers of particular issues they remembered as meaningful to them in their own history with the magazine, and many took photos with the cover of the month and year in which they were born. Visitors also lost themselves in drifting through the issues, observing how MMS’s covers have marked the passage of time as reflected in manufacturing technology as well as the concerns and priorities of the day. (Our cover from September 1951 bore the copy “Drilling Holes in Communist Hopes.”) Many of the topics haven’t changed—we have been talking about the challenges of hole making for a long time, and a cover story on creep-feed grinding from decades ago caught my attention since that topic will appear on the cover of the next issue you see. Meanwhile, many of the topics have steadily transformed. MMS covers have documented the progression from punch tape to CAM to cloud computing. New technologies appearing, gathering strength and taking their place is an ongoing story spanning decades, and we are gratified to see how we are still watching and documenting that story today.

Related Content

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreProtecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

Read MoreGive Job Shop Digitalization a Customer Focus

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More