3D Printing Aids Setup at Caterpillar

Lightweight 3D-printed models have helped the heavy equipment manufacturer save time and money.

Share

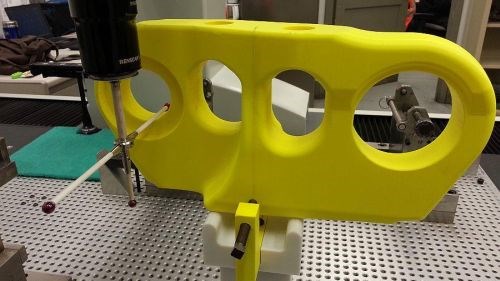

3D-printed models like this allow Caterpillar to set up CMM programs and other systems before foundry parts arrive.

A long-term goal of the Additive Manufacturing Group at Caterpillar is to explore how additive technologies like selective laser sintering (SLS) and fused-deposition modeling (FDM) could be applied for the production of end-use components, such as low-volume plastic parts or one-off replacements for legacy equipment. However, it has also found ways of improving current production with additively manufactured gages, assembly fixtures and other manufacturing aids.

The 3D-printed part shown above was created to speed up setup tasks for a production line. The part is a model of a forged track link, a component of the chain-like assembly found on dozers and other track-type equipment. In the past, workers would have used heavy models made from wood when creating fixturing and programming CMMs. Or, they would have waited for the parts themselves to arrive from the foundry. With 3D printing, Caterpillar made 36 ABS polycarbonate models of the track link. The lightweight models were much easier to handle and allowed employees to complete setup more quickly. The company estimates that making this change saved $160,000 in time and labor. Read more about additive manufacturing at Caterpillar.

Related Content

-

The Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

-

A Fond Farewell to My Additive Friends

In his final “Additive Insights” column, Tim Simpson reflects on how additive manufacturing has progressed in the last six years. Standards and software are two examples.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

.jpg;width=70;height=70;mode=crop)