Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Originally appeared on our sister site, Additive Manufacturing.

Cutting tool maker Kennametal used additive manufacturing to answer a machining challenge in electric vehicle (EV) production. The motor housing of an EV includes a large, precise bore for the motor’s stator. Machining this bore rapidly calls for a large-diameter tool — potentially too heavy for the machine tool intended to use it. Enter additive manufacturing! Kennametal engineers designed a large, lightweight boring tool made through laser powder bed fusion along with carbon fiber composite. | This episode of The Cool Parts Show brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related resources:

- Cutting tool maker Kennametal

- Our previous cutting tool episode, featuring an end mill made through 3D printing

- Other AM successes for EVs, including the drive housing and batteries

Transcript:

Peter Zelinski

How additive manufacturing will help us make electric cars on this episode of The Cool Parts Show.

Peter Zelinski

I'm Pete.

Stephanie Hendrixson

I'm Stephanie.

Peter Zelinski

Welcome to The Cool Parts Show.

Stephanie Hendrixson

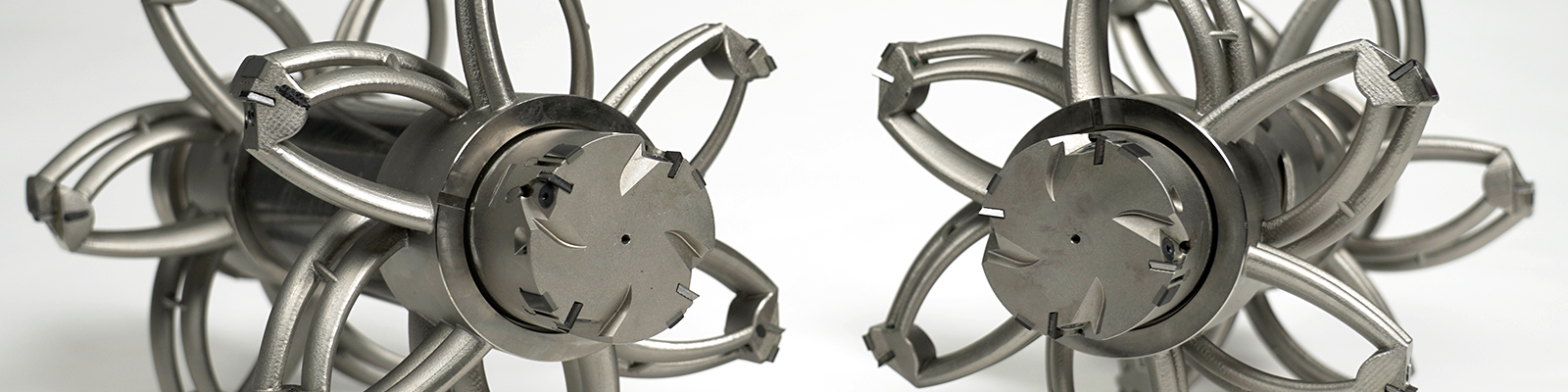

This is our show all about cool, unique, interesting, amazing 3D printed parts. And Pete, what is this crazy looking thing we're going to talk about today?

Peter Zelinski

So like, this looks intense, doesn't it? Um, let me tell you about this. This is the solution to a challenge in making electric cars. Machining is the answer to the challenge but 3D printing is vital to the machining.

Stephanie Hendrixson

Okay, so be a little bit more specific, how does this big cylindrical spiky thing help me make an electric car?

Peter Zelinski

The motor for an electric car, the housing of the motor has this big hole in it this big bore. It is the bore that holds the stationary part of the motor, the stator. It has to hold it precisely in the right position. So that bore is machined precisely and that's what this tool does, it precisely machines out that stator bore in a car's electric motor. But the thing is, this is automotive manufacturing so you have to make a lot of these housings, machine a lot of these bores, you got to do it efficiently. How do you machine it, that big bore, that big hole in the part. One way is a lightweight tool, maybe like in a helix shape, like to make that big hole, not very fast. Another alternative, like one really big honking tool, just like shoooom, just like machine the whole thing out in one pass, the problem there is that tool is liable to be super heavy, likely too heavy at that size for the machine tools that are doing this work to be able to wield a tool like that effectively. So the question is, can you make a tool that is both big and lightweight? Enter additive manufacturing.

Stephanie Hendrixson

Okay, so I'm with you so far. Electric vehicles need these large stator bores, the fastest way there is to use a very large cutting tool. But building a tool this large conventionally might mean that it is too heavy for the machine tool to use. And so here, 3D printing is providing the lightweighting, right? Except this tool does not feel lightweight at all.

Peter Zelinski

So yeah, like lightweighting is relative, isn't it? For reference, a tool this size made conventionally, a comparable tool made without additive manufacturing probably weighs twice what this tool does, two times. And a tool that heavy like so the machine tool in question, it probably wouldn't be able to swing a heavy tool like that around in its tool changer and load it up into the spindle and the weight might deflect and might work against the tolerances you're trying to hold because of all of that mass. Yeah, this is still kind of heavy when you try to pick it up, but it's super light for a tool this big. And that's what additive manufacturing brings, that like cutting the weight in half at least results in a tool that is light enough for the machine tools to use, make use of effectively to efficiently machine these big precise holes.

Stephanie Hendrixson

Okay, very cool and I want to hear more about that. But let's talk 3D printing who made this and how?

Peter Zelinski

This tool was made by Kennametal, well-established cutting tool maker and Kennametal has an additive manufacturing group. And Kennametal is starting to take that additive manufacturing knowledge and apply it to cutting tool manufacturing. And the company has standard products now, off-the-shelf catalog products that are manufactured through 3D printing. But these are smaller tools. They're very small tools. This is an extreme case of additive manufacturing to make a cutting tool. Very big tool does a lot. We actually have two versions of this lightweight tool, including one that's even a little lighter than this one I'll get to that. But this one, this version, you can kind of see three metal 3D printed sections that were assembled together. Additive Manufacturing doesn't account for all of the components or all the functionality. These cutting edges, cutting inserts are made of a very hard material good for cutting metal made in a separate process. For more about this tool and how it's made, let me introduce you to someone. This is Werner Penkert. He is a manager for advanced machining and additive solutions for Kennametal.

Werner Penkert

We use laser powder bed fusion 3D printing processes to manufacture the steel components of this tool, which enables us to reduce the weight and incorporate complex geometries that would have been difficult or impossible with traditional manufacturing techniques. After creating the body of this tool, we use milling, drilling, EDM machining processes to create the pocket seat of the PCD, the polycrystalline diamond reaming inserts. We also epoxy PCD guide pads and grind them for precision. overall leverage of the 3D printing technology resulted in the part requiring significantly less machining having a much lower weight and allowing more complex geometries than traditional manufactured tools would have.

Stephanie Hendrixson

Okay, so we sort of started this conversation by talking about light-weighting. And I can sort of see some of the choices they made to reduce the material used to get the weight down. But from what Werner just said, I'm gathering that there's a little bit more going on, like what are the other design opportunities that they realized through 3D printing.

Peter Zelinski

So we've covered 3D printed cutting tools before. Do you remember that episode? And so it was a 3D printed endmill and part of the reason for 3D printing, in that case, was to get coolant through the tool, get the cooling fluid to flow through the body of the tool, with channels 3D printed in to sort of channel that cutting fluid exactly where you want it to go. Okay, so that's going on here too. And again, it's more extreme in this tool. So built-in coolant passages, all through this tool flowing through the body of this tool so that coolant exits everywhere these cutting edges need it, all around the tool, all around these cutting edges. And the coolant not only helps with the cutting, it helps with something else too. This tool's machining is so precise that in order to guard against the tool, rubbing against the inside of the bore, as it cuts, the pressure of the coolant, going through this tool and kind of spraying out in all directions at once, it guides the tool. The cooling itself acts as a hydrostatic bearing and it's part of the functionality of how this cutter precisely cuts.

Stephanie Hendrixson

Okay, so the 3D printing is actually doing a lot here. It's helping to provide the lightweight, it's allowing for those coolant channels that are actually guiding the tool. And the tool itself is doing a lot. It's cutting that big hole in just one pass.

Peter Zelinski

Can I jump in there because I've actually kind of undersold all that this tool does? There's even more going on than just machining one straight hole in one pass, it's actually machining a variety of different features. So this front part here, it machines the bearing surface, the place where the bearing for the rotor mounts, the rotor the part of the motor that spins inside of the stator. Very precise. Then this part, this sort of like array of cutting edges, that's what machines that long central bore, the stator bore. And then this part at the back, it's actually cutting at a diameter that's a little larger than this first section. And that larger diameter, it creates sort of the recessed surface where a cover plate goes in. All of that has to be machined at very tight precision. And in fact, this bearing mounting section, in particular, it has to be on centerline with the rest of this larger bore. So precisely like the margin for error is something like 20 microns. And so having this one big, solid tool, it allows for accuracy and efficiency all at the same time. All of these different features are machined in that one pass.

Stephanie Hendrixson

So this is not just one 3D printing cutting tool. This is like three cutting tools all together doing three different things all at the same time.

Peter Zelinski

So Yeah, at the very least, this one tool performs a series of operations and it replaces at least three different tools.

Stephanie Hendrixson

Okay, so where are they at with this? Is this a tool that's actually being used in automotive production right now?

Peter Zelinski

Yes, a different version of this is. So let me show you like the next iteration of this design. It's a little lighter weight, it's a little lighter weight. And you can see the difference here. You can see the difference. So, the simplest 3D printed section which is this sort of central shaft, in this next iteration, it was replaced with carbon fiber composite. And so this is cutting tool maker Kennametal basically using all the different options and technologies they have available to try to get the lightest weight, best performing tool they can. So these cutting sections are still made through additive manufacturing and looking for a little more weight savings using carbon fiber composite.

Werner Penkert

So both versions of the tool provide a significant advantage in terms of weight. Our all-steel version is 10.7 kilograms, which equals 23.5 pounds. Our steel CFRP steel version has a weight of nine and a half kilograms, which equals 21 pounds. Compared to the conventional aluminum or steel tool bodies, that represents about 40 to 50% weight reduction. That matters because spindle interfaces are limited with weight and momentum of inertia.

Peter Zelinski

So you asked has this been adopted? And the answer is yes. So these tools are demonstrator models. This is Kennametal's engineering team demonstrating, proving out that a tool like this is a powerful effective solution for manufacturing electric vehicles, electric motors. And yeah, there is one automaker who is convinced this is the effective way to go. And the tool has continued to develop. That automaker, along with Kennametal has refined this design and sort of taken it to the next level improved it even more. But essentially, yeah, this tool is now used in serial production day after day, producing electric motors for EVs.

Werner Penkert

Our mission is all about improving performance for our customers. We want to help them to cut faster, run longer, and machine with greater precision and process security. We see this 3D printing as a key innovation enabling technology because it offers huge opportunity to improve performance and deliver value to our customers. It enables lightweighting with strength, production of complex parts not possible with traditional methods, optimizes the design and the performance. The demonstrator tools generated interest from a number of customers from the automotive industry, their tier one, tier two, and their broad subcontractor base. e are currently implementing an enhanced version of the steel CFRP steel version into the production of a serial production of an automotive OEM customer.

Stephanie Hendrixson

Okay, I think I've got this. So these are two different versions of a cutting tool made with 3D printing. They are designed to cut the main stator bore in an electric vehicle motor housing. But actually, they're doing a little bit more than that. They're cutting the main bore but they're also cutting the bearing seat and the housing cover seat. So it's really like three different tools in one. So creating a cutting tool this large allows you to cut all those three things in just one pass, which saves you a lot of time. But building a tool like this conventionally would mean that it's probably too heavy for your machine tool to handle and that might influence the kind of cutting results that you get. So Kennametal, which is an established cutting tool company, took a stab at creating a new type of cutting tool. They developed this design first looking to save weight, and they reduce the weight by about half versus a conventional version. But moving to laser powder bed fusion also allowed them to include these internal cooling channels to help this tool be even more efficient and functional. Looking for additional weight savings, they then went to this design which incorporates a carbon fiber body in place of the 3D printed piece. And a version of these tools is actually currently being used in the production of electric vehicles.

Peter Zelinski

Thanks for watching. This is actually the second time we've gotten to talk about 3D printing for tools for machining. We'll put a link to the earlier episode about a 3D printed cutting tool in the show's description. Find all of our previous episodes at TheCoolPartsShow.com

Stephanie Hendrixson

If you liked the show, we hope you'll subscribe leave us a like leave us a comment and if you have a cool 3D printed tool or other parts, you can email us at CoolParts@AdditiveManufacturing.media. Thanks for watching.

Peter Zelinski

This episode is brought to you by Carpenter Additive. We are at the company's powder production facility in Athens, Alabama and we are standing on top of an atomizer. The Z1 is Carpenter Technology's largest vacuum atomizer and it is the heart of the process for making additive manufacturing metal powder here at Carpenter Additive.

Stephanie Hendrixson

This facility is capable of producing up to 18,000 pounds of metal powder per day. Plant Manager Jordan Ralph talked us through the process.

Jordan Ralph

So an atomizer is a piece of equipment that is capable of melting and pouring molten metal into the stream of high-pressure gas that turns that molten metal into tiny tiny droplets that ultimately cool and form our powder which looks like grey dust. So to start our process in the ultimate end-to-end solution that we have here we bring in raw materials, all the way down to individual elements. So nikel, cobalt, chrome, moli, niobium, we bring all of those raw materials into the shop, we utilize those materials to build charges that go into the atomizer. As you walk that flow path, you run through our charge makeup area where all of the materials are weighed out in very exact quantities. That ensures that we're able to hit our customer specifications and hold the tight tolerances that we're looking for on a chemistry perspective. From there, the material is flown to the top of the atomizer and charged into the furnace. As the materials produced it is poured out and is collected at the bottom of the atomizer. The material is then taken and transferred into a bulk container for processing through the rest of the value stream. The next stop for any of our atomized powder would be the screener. So that will remove the course portion of the powder. From there, we take it through air classification that takes the fine portion of the particle size distribution out and makes the final cut for an additive material like a 10 to 45. From there, we stack up all of those individual lots and put them into the 12,000 pound blender to make the single homogenous blends. At that point, we're able to pack in any configuration that the customer is looking for, whether that be drums, bottles, PowderTrace hoppers, we've got a lot of options to meet the customer's needs. The atomization capability and all of the powder capabilities gives us a unique position where we're actually able to produce the powder, run testing through additive machines all the way through hip and heat treat, do final testing on those products, and then make additional changes or try to optimize you know things like our chemistry or sizing so that we ultimately can serve our customers better.

Related Content

JTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreDesigning a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read MoreRead Next

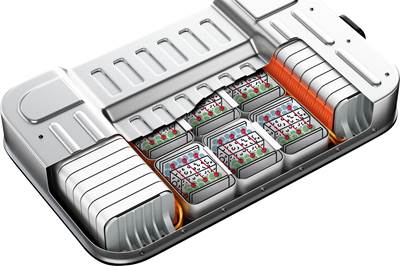

Photocentric Explores How 3D Printed Battery Electrodes Could Drive Electric Vehicles Forward

Precise control of battery electrode architecture through photopolymerization opens the door to new cell geometries and lighter battery packs for EVs and more, Photocentric says.

Read MorePorsche Advances Electrification with Generative Design

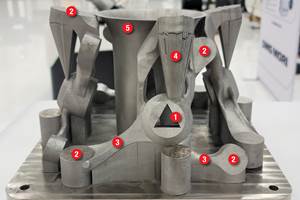

The sports car manufacturer achieves weight savings and assembly consolidation using additive manufacturing instead of casting for an electric drive housing.

Read More3D Printed Tool for CNC Machining: The Cool Parts Show #17

Guhring uses additive manufacturing to make an end mill with optimized internal channels. We visit a machine shop to test the tool on this episode of The Cool Parts Show.

Read More