Turning Machines

“Turning” defines the work that is traditionally done on a lathe. “Turning centers” is a term sometimes applied to machines with secondary spindles and/or rotating tools for milling and drilling. Another term, “turn/mill or multitasking” describes machines that can be thought of as being just as capable at milling and drilling as they are at turning. Lathes, turning centers and turn-mill machines can have horizontal or vertical spindles, with horizontal being most common. Machines with a vertical spindle are generally called a vertical turret lathe, or VTL. If the workpiece is held from above by the vertical spindle, then this type of turning machine is generally called an inverted vertical lathe.

ESSENTIAL READING

VIEW ALL4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreHow to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.

Read MoreBuying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Read MoreThreading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read MoreChoosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

Read MoreLatest Turning Machines News And Updates

The Human Impact of Machining Technology

SSP’s commitment to adopting the latest machining technology benefits not only the business, but its employees as well.

Read MoreFacilitating Lean Manufacturing Through Modularity

Knowing how to subdivide machines and jobs has enabled Danobat to create a lean manufacturing process that improves its lead times by up to 25%.

Read MoreRomi Turning Machines Provide Enhanced Precision

IMTS 2024: Romi features both a custom CNC lathe and a 12-axis horizontal turning center for wear resistance and precision in turning, milling and drilling operations.

Read MoreDN Solutions Announces Twin Spindle, Twin-Turret Horizontal Turning Center

IMTS 2024: DN Solutions introduces a twin spindle, twin-turret horizontal turning center with 4″ bar capacity for increased productivity and simultaneous machining performance.

Read MoreCustom Motorcycle Parts Made Here: Video Tour of a Family-Owned CNC Machine Shop

Lee Wimmer invited us to tour his second-generation family-owned machine shop in Perkasie, PA. This video explores the production processes behind precision-machined parts for both Wimmer Custom Cycle and LS Wimmer Machine Co., and shows how ingenuity and determination are still at the heart of American manufacturing. Today, both companies are now managed by Wimmer’s three sons.

Watch4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreFeatured Posts

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read MoreSecond B-Axis Improves Efficiency of Swiss-Type Machining

A highly stable, fully programmable B-axis on the subspindle of Nomura DS’s 20J3XBTC enables users to more quickly machine complex parts complete.

Read MoreIndustry Analysis: Machining Semiconductor Components

With many machine shops anticipating long-term growth in demand from the semiconductor industry, it is worth the time to heed the advice of manufacturers who have already been servicing this end-market for years.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreFAQ: Turning Machines

What is turning?

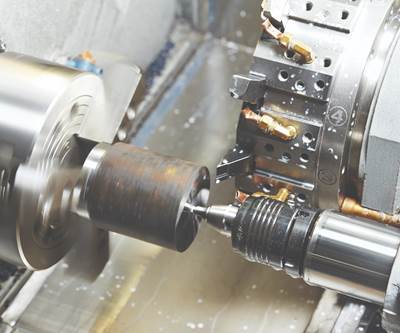

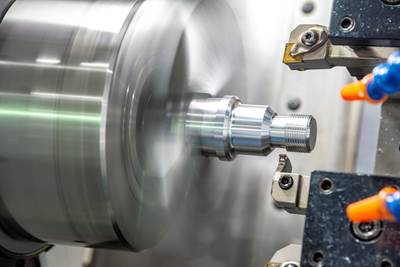

Turning is the process of using lathes to remove material from the outer diameter of a rotating workpiece. Single-point tools shear metal from the workpiece in (ideally) short, distinct, easily recyclable chips.

Source: Machining 101: What is Turning?

What is a lathe?

One of the key characteristics of a lathe, unlike a vertical or horizontal milling machine, is that the workpiece turns, as opposed to the tool. Thus, lathe work is often called turning. Turning, then, is a machining process used to make round, cylindrical parts.

Source: Buying a Lathe: The Basics

What is the basic configuration of a lathe?

The basic two-axis lathe consists of a headstock with spindle, chuck for holding the part, lathe bed, carriage and cross-slide, tool turret and tailstock. While most lathes have a moveable tailstock to support the workpiece at the end, away from the chuck, not all machines come with this feature as a standard. A tailstock is particularly useful, however, when the workpiece is relatively long and slender.

Source: Buying a Lathe: The Basics

What kinds of spindles do lathes typically have?

The spindle on a turning center is either belt-driven or direct-drive. Generally, belt-driven spindles represent older technology. They speed up and slow down at a lower rate than direct-drive spindles, which means cycle times can be longer. If you’re turning small-diameter parts, the time it takes to ramp the spindle from 0 to 6,000 rpm is significant. In fact, it might take twice as long to reach this speed than with a direct-drive spindle.

What are the types of programmable tailstocks?

A built-in, numerically controlled tailstock can be a valuable feature for automated processes. A fully programmable tailstock provides more rigidity and thermal stability. However, the tailstock casting adds weight to the machine.

There are two basic types of programmable tailstocks—servo-driven and hydraulic. Servo-driven tailstocks are convenient, but the weight they can hold may be limited. Typically, a hydraulic tailstock has a retractable quill with a 6-inch stroke. The quill also can be extended to support a heavy workpiece, and do so with more force than a servo-driven tailstock can apply.

What are some variations of the basic lathe configuration?

Slant-bed lathes provide a number of advantages, while multitasking lathe configurations might open up possibilities heretofore unthought of.

The slant-bed lathe design is probably the most common and well-known configuration in today’s CNC lathes. Typically, the bed of the lathe slants at a 30- or 45-degree angle, although some 60-degree models also are available.

Multitasking machines are often built on a turning center platform. These machines use rotary tools to combine several cutting processes such as turning, milling, drilling, tapping, grooving, threading and deep-hole boring on one machine.

Source: Buying a Lathe: Slant-Beds and Multitasking Configurations

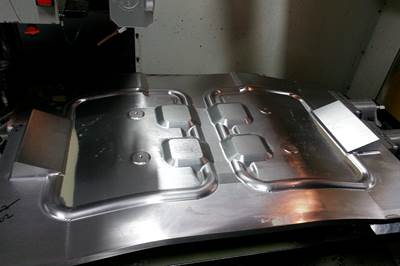

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)