Top Shops 2013: JD Machine

Benchmarking is important to our 2013 Business Strategy Honors Program winner.

Share

Benchmarking Value

Shop owners and managers rarely get a chance to see others’ machining processes. Therein lies the value of our magazine’s application stories, which the other editors and I create after visiting a shop. Benchmarking data offer the same benefits because that information provides insight into leading shops’ performance, processes and practices.

Matthew Wardle, president of JD Machine, uses benchmarking to help guide change at his Ogden, Utah shop. (JD Machine is the 2013 Business Strategy Honors Program winner.) Mr. Wardle took over as company president from his father in 1992. JD Machine is the only business for which he has worked, so he understands the importance of comparing his shop’s performance against others and considering the business- and technology-related strategies successful companies are leveraging.

This is why Mr. Wardle and his management team try to obtain as much benchmarking-related information as possible. He says this is one benefit to being a member of the National Tooling and Machining Association (NTMA), which conducts an annual survey of its members to provide data related to operating costs, executive pay, wages/benefits and so on. In addition, Mr. Wardle participates in the annual Top Shops benchmarking survey, which he says nicely complements NTMA’s survey.

Some of the Top Shops benchmarking information he and his team closely review include profit margin, sales per employee, spindle utilization and the lean manufacturing practices shops apply. They also look at pay rates for shopfloor personnel as well as the common benefits that shops offer. There are a number of shops in Utah, but not many of them are as big as JD Machine. Therefore, the company oftentimes has to look outside the state to find new employees. The human resources benchmarking data helps to ensure it is offering a competitive wage and benefits package, Mr. Wardle says.

Overall, benchmarking data show where JD Machine is performing well and where there’s room for improvement. In addition, the shop uses benchmarking data as part of its strategic planning and SWOT (strengths, weaknesses, opportunities and threats) analysis as it set goals for each new year.

Company Description

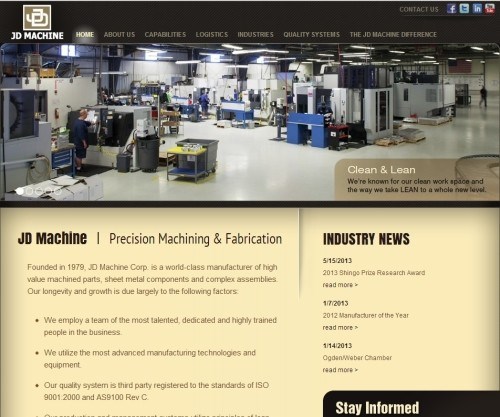

Located in Ogden, Utah, JD Machine is a manufacturer of precision-machined components for customers in various industries. Because the company recognizes the vital impact its employees have on all facets of the business, it provides a working environment that fosters growth while identifying individual and team contributions. JD Machine's lean manufacturing mindset drives continuous improvement and encourages close employee involvement. As shown below, it posts performance metrics and has monthly meetings with employees to discuss how it is performing compared to its goals.

The company’s 45,000-square-foot facility features a climate-controlled manufacturing area, dedicated assembly room and energy-efficient building elements. It also maintains shopfloor organization through strict adherence to 5S principles.

End Markets Served

- Aerospace

- Communication

- Defense

- Energy

- Medical

- Nuclear

Workpiece Materials Commonly Machined

- Aluminum alloys

- High-temp alloys

- Nickel-based alloys

- Plastics

- Stainless steel

- Titanium

- Tungsten

JD Machine

2744 North Parkland Blvd.

Ogden, Utah 84404

Phone: 801-782-4394

Fax: 801-782-4398

Related Content

Creating a Learning Culture at JD Machine

JD Machine, 2024’s Top Shops Honoree in Human Resources, embodies its “Education for Life” core value with a robust apprenticeship program and significant continuous improvement efforts.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreBenchmarking: An Invaluable Business Tool

Modern Machine Shop’s Top Shops program shows shops their strengths and opportunities for improvement, and provides recognition for high-performing businesses.

Read MoreFinding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More