More In The Know

This shop is in the early stages of integrating Internet-based training tailored specifically to the brand of Swiss-type lathes it uses. The goal is to bring prospective employees up to speed quicker while enabling existing employees to progress to more advanced roles in the shop.

Share

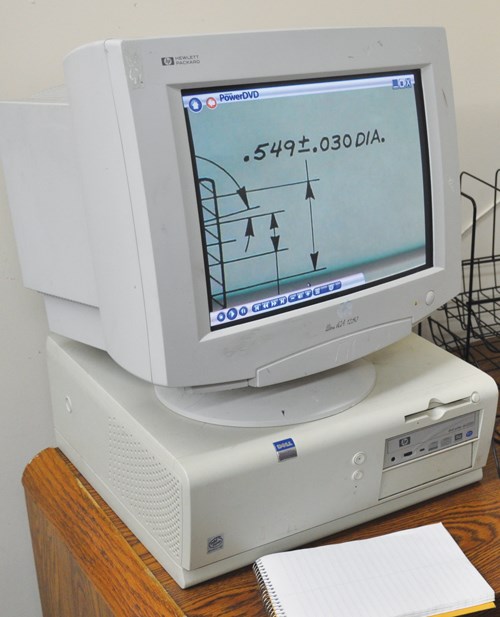

This video from the MasterTask training course for Tsugami Swiss-type lathes demonstrates how to adjust the main collet tension on a Tsugami machine.

Business for Swissline Precision was down last year, but the New England shop faired much better than others in its area. And things are starting to pick up. The shop’s manufacturing engineer, Mike Chenevert, attributes this to two key resources.

The first is its wealth of advanced machining equipment. The Cumberland, Rhode Island shop specializes in intricate Swiss turning work. It currently has 48 Tsugami Swiss-types it purchased through REM Sales, although this number is likely to grow. That’s because the shop continues to add capacity to keep pace with the latest sliding-headstock turning technologies. In fact, it purchased nearly $2 million in Swiss-types from 2004 to 2009 and is expanding its floor space to meet an increasing workload.

The second is its dedicated workforce. Swissline employs 52, and many of those people have been there for more than a decade. Shop management understands the importance of supplying these valuable employees with the tools they need to perform their duties efficiently and effectively. Examples of those efforts are evident when touring the shop.

For instance, all shopfloor workers wear eye loops around their necks so they can quickly scan the small, precision-turned parts the shop produces. Optical comparators and stereo microscopes are spread throughout the facility, too, so more powerful inspection capabilities are never far away. Likewise, 5S organizational efforts reduce the time it takes to find tools, gages and other essential items. In addition, heavy use of macros streamlines the creation of new part programs. Oftentimes these programs include helpful process alerts, such as those that flag operators to change an insert after a specified part count so they don’t have to keep close track of tool usage.

One of the best examples of Swissline’s willingness to invest in its employees is the new approach to training it is adopting. The shop recently began using online machining courses—courses tailored specifically to the brand of Swiss-types it uses—as part of a more formal process to instruct both existing employees and new prospects. The shop’s goal is to bring new hires up to speed quicker on its multi-function machines while giving eager employees the chance to assume more advanced roles in the shop. Mike Chenevert described the shop’s initial efforts to apply this new training approach during a recent visit.

Machine-Specific Training Tool

David Chenevert, Mike’s father, reinvented Swissline which, in 1985, was in a garage and featured six cam-driven Swiss machines. Today, the operation resides in a 36,000-square-foot facility that includes the aforementioned CNC Tsugamis plus some Okuma turret lathes and Akebono gang-tool lathes. Swissline, which is certified to both ISO 9001-2008 and ISO 13485-2003 standards, has made a name for itself machining complex parts from tricky alloys primarily for medical, aerospace and fluid handling customers.

While it’s burdensome for most shops to find and then train new employees in-house, such exercises can be more daunting for Swiss-turning shops. Experienced Swiss machine operators and setup personnel are few and far between. Plus, sliding-headstock lathes are fundamentally different from conventional lathes, meaning prospects who might have a wealth of experience with standard CNC turning equipment still often struggle when placed in front of a Swiss machine. After all, these lathes move the material to the tool rather than feeding the tool to the material, and they can often perform operations on both their main and subspindles simultaneously.

Swissline had applied what might be considered conventional in-house training methods, whereby new hires essentially shadowed experienced operators as they learned the ropes. Once those new employees were deployed out on their own, they often still required some support from veteran workers until they became comfortable with the Swiss machines. Both of these situations hamper the shop’s key personnel in effectively carrying out their own production duties.

At a recent Eastec trade show, the senior Mr. Chenevert discovered an online instructional course developed by MasterTask Training that offers an alternate training approach for shops like his. In fact, the detailed courses are tailored specifically to the brand of Swiss-types that the shop uses. The Swiss machining course for Tsugamis is divided into 77 instructional sections (courses for Star and Citizen equipment are also available from MasterTask). Preliminary sections explain the basics of the machine coordinate system and introduce primary machine components, including the bar feeder, guide bushing, sliding headstock assembly and main and sub-spindles. Subsequent sections address more advanced concepts, such as programming codes, machining cycles, collet tension adjustment, live-tool setup and process troubleshooting.

The courses use photos and videos of actual machines in addition to simulations of primary mechanisms and components. For example, the Fanuc control common to the shop’s Tsugamis is accurately depicted, allowing trainees to become comfortable with the control’s screen, buttons and overall interface. These real and simulated representations help acclimate trainees to a complex Swiss machine without tying up an actual one for instructional purposes.

Employees can progress through the course at their own pace. However, they cannot advance to a new section until they pass the previous one. Most sections last 10 minutes, and users are able to review each section as often as needed before being tested. Shop administrators can log in to track how long it took users to complete sections, how many times it took them to pass tests and so on. This allows supervisors to identify subject matter with which trainees seem to struggle.

Initially, Swissline asked two employees to take the online course: David Hamel, who has been with Swissline for 11 years, and Gordon Morissette, who has worked there for a year and a half. Since completing the course, both commented that they have a much better understanding of the inner workings of the machines they operate. They also say that they can more easily follow along with what’s being executed in a part program, even though they admittedly don’t have the chops to fully program a job yet.

Mike says the guys’ confidence levels have risen a great deal since taking the course, and they no longer require basic direction when running their jobs. On the other hand, the two are more apt to ask the types of questions that might result in improving an existing process, he notes. For example, they may question the type of insert used for a job if the current one is generating sub-par finishes. Alternatively, they may ask whether an increase in speed might give the insert the chip load it likes to cut more effectively. They are also more likely to notice subtle problems that may have previously gone unnoticed and undiagnosed, such as an oversized channel set installed in a bar feeder that causes the stock to whip around while rotating.

A more solid understanding of Swiss turning principles has also enabled these operators to more quickly advance from straightforward machine layouts to more complicated ones. The two machine photos to the right show the type of jump the training course facilitates. The Tsugami Swiss-type that David Hamel is operating cannot perform operations on both the main and subspindles simultaneously, while the machine shown in the following photo can perform these overlapping operations.

Rapid progression to more complex machines is ultimately what the shop hoped the online courses would provide for its existing operators, Mike explains. There’s always the risk that a well-trained person may be lured away by a competing shop offering a bit more money. However, taking a gamble on integrating comprehensive, in-house training is better than the alternative of having a stagnant workforce that’s not becoming better or more valuable to the company.

Related Content

Workholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

Read MoreFinding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreManufacturing Madness: Colleges Vie for Machining Title (Includes Video)

The first annual SEC Machining Competition highlighted students studying for careers in machining, as well as the need to rebuild a domestic manufacturing workforce.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)