Workholding

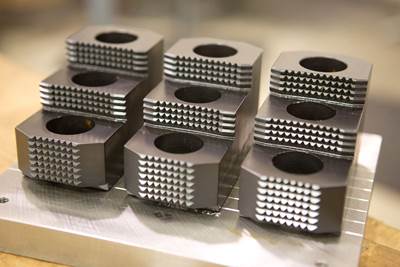

Dillon Manufacturing Provides Top Jaws With Custom Dimensions

Dillon’s custom, special or modified hard-, soft- or full-grip top jaws are said to be compatible with virtually any chuck manufacturer.

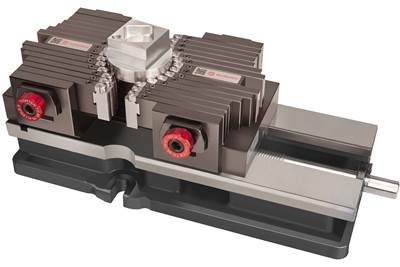

Read MoreKurt Workholding Adds New Compact Robotic-Arm Gripper

The RV24 Robotic Gripper’s design enables automated finger/end effector changes without changing the gripper body itself.

Read MoreModern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

WatchInternal Clamping Collet Adapts to Workpiece Contours

Andreas Maier GmbH & Co. KG’s new collet attachment can be machined to match the internal contour of the workpiece.

Read MorePhillips Precision Introduces Flexible Fixturing System

Phillips Precision’s Cross-Member turns any clamp or vise on its side, providing more versatility for access to critical part features.

Read MoreChuck Lubricant Prevents Metal-to-Metal Contact

Dillon’s HPG500 premium boundary lubricant is said to have exceptional mechanical stability, very high load carrying capacity and excellent water and moisture resistance.

Read MoreSchunk Makes a Gripping Debut at IMTS

By taking inspiration from gecko feet, Schunk has developed a residue- and particle-free adhesive robotic gripper that holds up to 35 pounds.

Read MoreNew Direction: An Interview with Kurt Manufacturing

IMTS 2022: Brent Donaldson, executive editor of Modern Machine Shop, sits down with Paul Carlsen of Kurt Manufacturing, to chat about the company’s redesigned booth and how it’s designed to solve customer problems.

Read MoreNew Division, New Product: An Interview with Norgren Workholding

Brent Donaldson of Modern Machine Shop chats with Corey Shidler of Norgren Workholding on the company's new soft jaw.

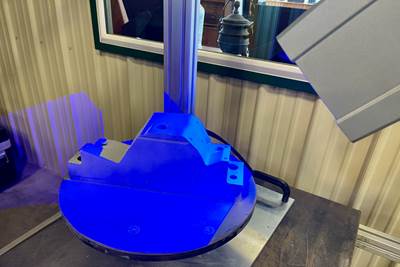

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read More