Turning Tools

Lathe Toolholder Allows Quick Insert Changes

This lathe toolholder allows insert changes in a matter of seconds with the push of a button. Its cam-actuated lever provides a uniform insert clamping pressure of 8,000 psi.

Read MoreInsertable Tooling With 90-Degree Angle

Thinbit, manufactured by Kaiser Tools, has expanded its Groove ‘N Turn line of insertable tooling. The inserts have a 90-degree included angle for producing chamfers. They are available in three grades of material: D2 for steels; D5 for non-ferrous and HSS; and TiN, TiCN and TiAIN are also available.

Read MoreSmall Face-Grooving And Turning Tools

Iscar says that the Mincut family of small-face grooving and turning tools is designed for high machining rates, and it is suited for applications prone to high tool failure rates. The tools incorporate a special design and clamping system that is said to prolong tool life. The line of tools includes eight inserts that are screw-clamped into a long pocket in the tool bar.

Read MoreTurning Geometry For Aerospace Alloy

ATI Stellram designed the 4E turning geometry to meet the demands of machining aerospace-type components manufactured from high nickel, high cobalt and titanium-based alloys. Available in grade SP0819, the inserts use an approved aerospace substrate and are enhanced with a nano-TiAlN layer PVD coating. Combining a super-hard coating with a micro-grain carbide substrate significantly improves heat and wear resistance in high-temperature alloy machining, the company says.

Read MoreFace Driver Cuts Large-Sized Workpieces

The Neidlein FSB 75 face driver from LMC Workholding is used to efficiently cut large-sized workpieces. The face driver is able to make heavy cuts on large barstock and forged workpieces up to 12 ft. long, 28″ in diameter and weighing as much as 13,000 lbs.

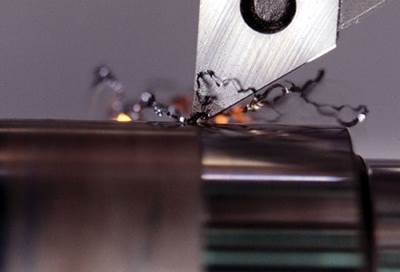

Read MoreChipbreaker For Steel Turning

Seco Tools offers its MR6 chipbreaker optimized for peak performance in the medium-rough turning of steels. The chipbreaker’s main advantage is the open and highly positive design coupled with the company’s Duratomic coated grades, allowing for the use of higher cutting speeds when compared to traditionally designed chipbreakers, the company says. The chipbreaker generates low cutting forces within the main cutting area allowing high cutting speed, depth of cut and feed, which increase machine utilization and productivity for the customer.

Read MoreSpinning Turning Tool Offers Alternative To Single-Point Cutters

CAM developer DP Technology recently performed a successful test cut of a new cutting tool for turning applications that is designed to reduce vibration and heat buildup. The company's CAM software package, Esprit, now contains an add-on for programming the new tool. Developed jointly by machine tool builder Mori

Read MoreThe New Rules of Cutting Tools — Introduction

Cutting tool technology is evolving rapidly to respond to changing demands and more challenging workpiece materials. Shops today need to look at cutting tools differently. They need to look at cutting tool suppliers differently as well.

Read MoreThe New Rules of Cutting Tools — Rule #1: Do More With Your Machine

The tooling has the potential to transform the process.

Read MoreThe New Rules of Cutting Tools — Rule #3: Diamond Shouldn't Be Rare

Consider PCD or CBN wherever capacity is tight.

Read More

.png;maxWidth=300;quality=90)