Turning Tools

Turning Grade Designed For Demanding Environments

Valenite’s VP9605 is designed for difficult-to-machine materials and for aerospace industry applications such as semi-finishing and finishing. According to the company, the turning grade offers production cost savings and increased tool life.

Read MoreSteel Cutting Grade For High Speed Turning Applications

Mitsubishi Materials offers the UE6105 steel cutting grade. This grade represents the latest two-in-one, nano-texture coating technology designed for increased wear resistance at high surface feet per minute.

Read MoreSee The Tool's Value Instead Of Its Cost

This company is embracing high-performance tooling on its turning centers. The "sticker shock" is no reason not to do this. In one case, though, the shop found a way to limit the cost of the tool and increase productivity at the same time.

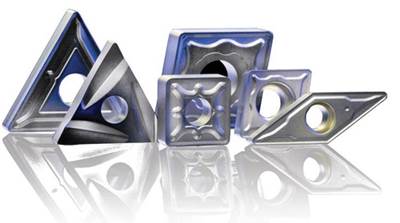

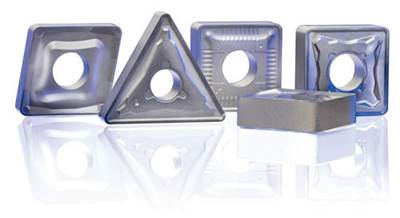

Read MoreGrades Improve Titanium Turning Productivity

Kennametal’s Beyond line of high-performance turning products includes 11 additional grades for improved productivity in steel, stainless steels and cast iron applications. The latest grade, KCS10, is a medium positive (MP) geometry with the capability of improved titanium designed to improve surface finish while extending tool life.

Read MoreSteel Turning Grade Family Expands

Valenite introduces its tough grade, VP5635, to the 5600 series steel turning grade family. For applications such as roughing steels, stainless steels and cast iron, this grade is said to increase production cost savings and lower total production time.

Read MoreInserts Offer Long Life, Tight Tolerances

Kennametal has added screw-on, positive chipbreaker inserts to its Beyond line, which includes 11 grades for improved productivity in steel, stainless steel and cast iron turning applications. The chipbreaker inserts, which include the FP (finishing positive), MP (medium/roughing positive) and MW (flat top) models, are said to provide significant tool life savings across a range of applications and materials. Additionally, the inserts’ tight dimensional tolerances can improve indexability, the company says.

Read MoreSwiss Tooling Line Covers Range Of Applications

Swiss tooling and a range of machine-specific adapters from European manufacturer Dieterle are now available in North America from the CIMtek group. The Dieterle line includes the Eco-Star Extrenal Tooling System, which consists of hardened and tempered toolholders designed for easy insert change and precise insert location. Featuring a pressed steel bushing, this design allows users to change inserts without removing the toolholder from the machine.

Read MoreLive Tools for Lathes

Designed to enhance the performance of a CNC lathe, the company offers a variety of live tools. These tools are designed to improve milling, drilling and tapping capabilities in turning operations. The company stocks a range of standardized live tools for CNC turning centers from major builders.

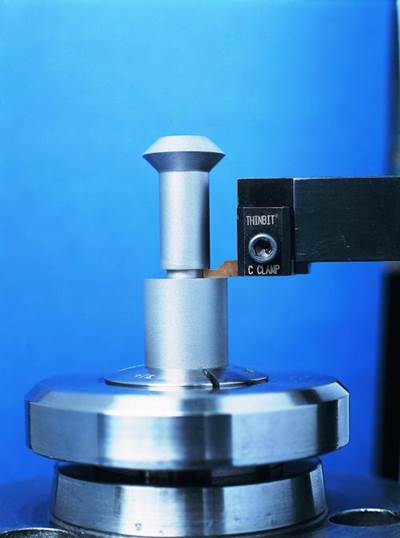

Read More10 Considerations When Using Grooving Tools

The dynamics of chip formation and evacuation make grooving in turning operations unique in almost every way. Innovative insert designs and coatings can improve your grooving operation, but to be completely successful, there are some other things you should know.

Read MoreMultitasking Tools Cut More Than Grooves

Once, grooving tools were only thought of for making grooves or cutting off the part. Improved designs, materials and coatings make them perfect sense as all-purpose tools under the right conditions.

Read More

.png;maxWidth=300;quality=90)