Turning Machines

Machine Tools Feature Integrated Control

Hurco features 11 machine tools with its integrated control powered by WinMax, which is software is designed to expand a shop’s capability. An interactive space with the control consoles is set up for booth visitors to test.

Read MoreVideo: Form Tools On CNC Lathes

Form tools are traditionally associated with non-CNC machines, but in certain applications they make sense on modern machines as well.

Read MoreVideo: Increased Productivity With More (Not Fewer) Setups

VIDEO. Valve maker Richards Industries took a part that used to machined at one machine tool and added an additional setup on a vertical machining center. Higher throughput was the result.

Read MoreHigh-Performance Universal CNC Lathe

Ganesh says its KSL-7612T heavy-duty boxway CNC turning center with Fanuc control is suited for manufacturers looking to reduce cost. It features full bar, chuck and shaft machining capability; 3" bar capacity; a 10" chuck; a 15.

Read MoreIf You Want to Improve Something, Measure It

This shop involves all of its employees in the daily exercise of analyzing just where time is being spent.

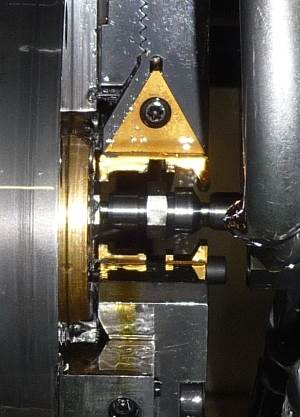

Read MoreHobbing on a Turning Center

This manufacturer’s use of live-tool lathes overcomes labor cost in various ways. One of the latest sources of savings involves bringing another operation—hobbing—into these machines. INCLUDES VIDEO.

Read MoreSubspindle Turning System Designed For Large Diameters

Bardons & Oliver’s Big Bore subspindle machine is designed for challenging through-hole applications. The heavy-duty, column-style machine can process complex bar and tube components with virtually no limitations on diameter, weight or length, the company says.

Read MoreSee The Tool's Value Instead Of Its Cost

This company is embracing high-performance tooling on its turning centers. The "sticker shock" is no reason not to do this. In one case, though, the shop found a way to limit the cost of the tool and increase productivity at the same time.

Read MoreThe Part Is Longer Than The Lathe

Here is one custom machine builder’s system for producing a 40-foot part that has to be passed through the turning center and out the other side. INCLUDES VIDEO.

Read MoreHigh-Performance Turning Center Built For Rigidity

The Quest CHNC turning center is available with either a 27-mm, 5C or a 42-mm, 16C collet-ready spindle. The machine is designed for high accuracy and quick job changeover to meet the demands of the medical, aerospace, defense and computer/electronics industries. This design configuration allows the use of top plates and tooling used on thousands of previous-generation CHNC machine installations worldwide.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)