Tooling

4 Considerations for Electropolishing Machined Parts

Manufacturers considering this non-contact finishing process should expect test runs and close collaboration with service providers before production begins.

Read MoreSetting Up and Operating Fine Boring Heads Just Got a Lot Easier

The combination of a digital boring head integrated with tool data software dramatically reduces the time required to set up a fine boring head. And still more IIOT-enabled advancements are just around the corner that will finally automate many boring operations.

Read MoreArch Global Precision Acquires Siem Tool Co.

The acquisition adds both carbide tool manufacturing knowhow to Arch’s Cutting Tools division as well as coating capabilities.

Read MoreAdvanced Machine and Engineering's Inverted Stud Ball Element Designed for Five-Sided Machining

Westec 2019: Advanced Machine and Engineering’s inverted stud ball element enables full five-sided profile machining, which decreases overall machine time.

Read MoreWhizCut’s WhizTwin Reduces Production Costs

EMO 2019: WhizCut’s WhizTwin cutting insert is said to reduce waste material by employing two cutting edges in the front for increased stability and strength.

Read MoreKitagawa NorthTech's DKF Collet Chuck Ideal for Tight Work Environments

The low-profile collet chucks in Kitagawa NorthTech’s DKF series feature a compact nose for when additional tool clearance is needed in tight turning environments.

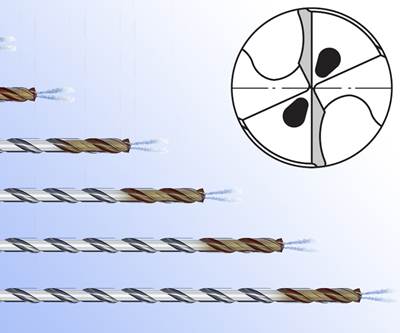

Read MoreMikron’s CrazyDrill Cool SST-Inox Delivers More Coolant for Deeper Holes

EMO 2019: Mikron Tool’s CrazyDrill Cool SST-Inox is able to machine small diameters and deep bores in stainless steels, nickel-based super alloys and CrCo-alloys because of its internal coolant ducts, geometry and coating.

Read MoreJM Performance Products Changes Material Used in Retention Knobs

Westec 2019: JM Performance Products has begun changing the material used in the production of its retention knobs from 8620H to 9310H grade steel.

Read MoreCeratizit Group’s FreeTurn Allows for 360 Degrees of Turning

EMO 2019: Ceratizit Group’s High Dynamic Turning (HDT) method combines its FreeTurn tooling systems with a turn-mill’s B axis or milling spindle.

Read MoreWhen a Swiss-Type Is a Lathe and a Five-Axis Mill

Swiss-type lathes with a swiveling B axis enable this shop to machine parts complete and unattended that it otherwise couldn’t using its five-axis machining centers. Here is some of what it learned adopting this new technology.

Read More

.jpg;maxWidth=300;quality=90)